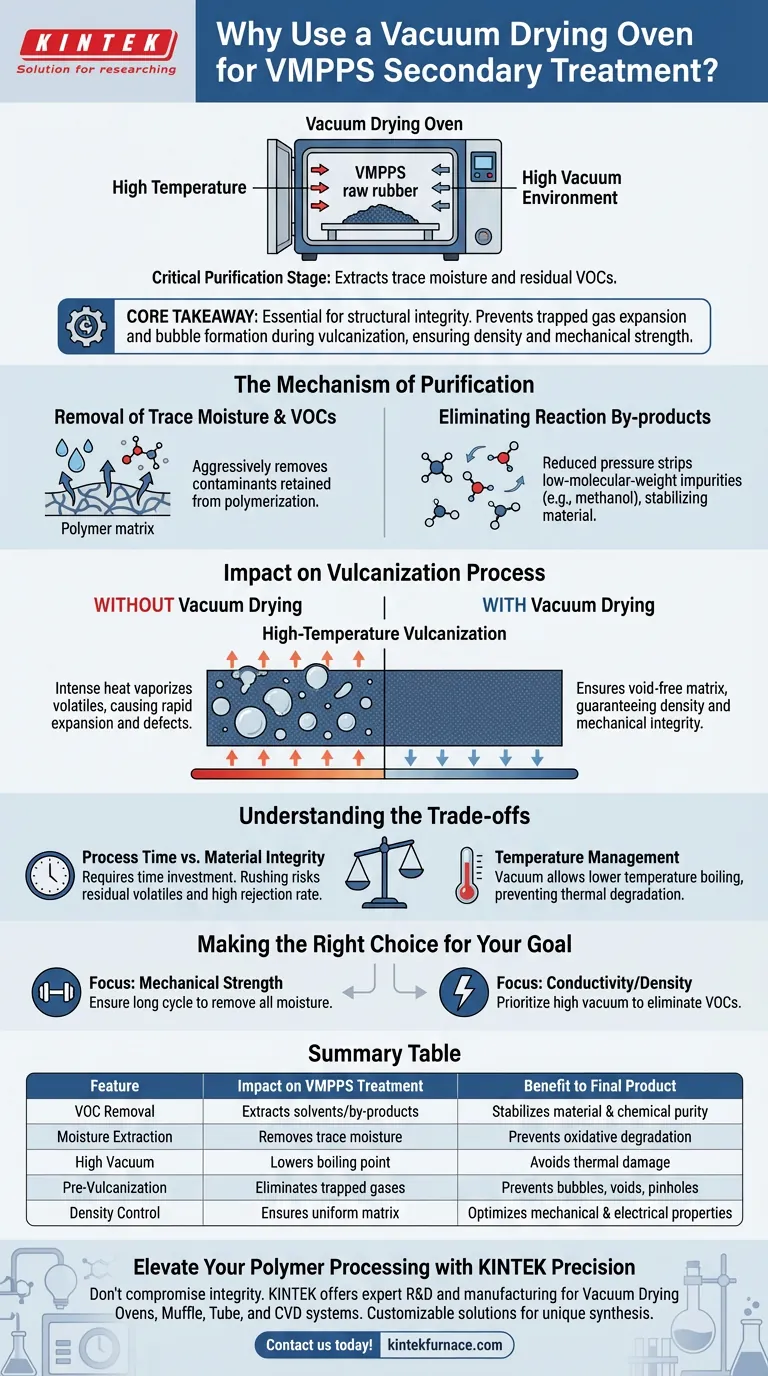

The secondary treatment of Vinyl Methyl Phenyl Polysiloxane (VMPPS) relies on a vacuum drying oven to act as a critical purification stage before final processing. By subjecting the raw rubber to a high-temperature and high-vacuum environment, the equipment forcibly extracts trace moisture and residual volatile organic compounds (VOCs) that are trapped within the polymer matrix.

Core Takeaway The vacuum drying process is essential for structural integrity, not just chemical purity. By eliminating volatiles prior to high-temperature vulcanization, this treatment prevents the expansion of trapped gases, thereby stopping the formation of bubbles and pinholes that would compromise the density and mechanical strength of the final conductive silicone rubber.

The Mechanism of Purification

Removal of Trace Moisture and VOCs

The primary function of the vacuum drying oven is the aggressive removal of contaminants. Synthesized VMPPS often retains trace moisture and residual volatile organic compounds (VOCs) from the initial polymerization phase.

Eliminating Reaction By-products

Beyond simple moisture, the process targets reaction by-products. Similar to vacuum distillation principles, the reduced pressure environment helps strip away low-molecular-weight impurities (such as methanol). Removing these components is crucial for stabilizing the material at room temperature.

Impact on the Vulcanization Process

Preventing Gas Expansion Defects

The subsequent step in VMPPS processing is high-temperature vulcanization. If volatile components remain in the matrix during this stage, the intense heat causes them to vaporize and expand rapidly.

Ensuring Material Density

This expansion creates bubbles or pinhole defects within the rubber. By using a vacuum oven beforehand, you ensure the polymer matrix is void-free. This guarantees the density and mechanical integrity required for high-quality flexible conductive silicone rubber.

Understanding the Trade-offs

Process Time vs. Material Integrity

While vacuum drying is effective, it introduces a processing bottleneck. It requires specific time and energy investments to reach the necessary equilibrium. Rushing this step (reducing time or vacuum levels) risks leaving residual volatiles, leading to a high rejection rate in the final vulcanized product.

Temperature Management

Although the primary reference suggests high temperatures for VMPPS, the vacuum environment fundamentally allows solvents to boil off at lower temperatures than they would at atmospheric pressure. This creates a safety margin that helps prevent thermal degradation or oxidation of the polymer backbone during the drying phase itself.

Making the Right Choice for Your Goal

To optimize your VMPPS production line, align your drying parameters with your specific quality targets:

- If your primary focus is Mechanical Strength: Ensure the vacuum cycle is long enough to remove all moisture, as even microscopic bubbles will act as stress concentrators and lead to failure.

- If your primary focus is Conductivity/Density: Prioritize high-vacuum levels to eliminate VOCs completely, ensuring a dense, uniform matrix that facilitates consistent electrical properties.

Secondary treatment is the invisible step that determines whether your VMPPS becomes a high-performance component or a defective scrap.

Summary Table:

| Feature | Impact on VMPPS Treatment | Benefit to Final Product |

|---|---|---|

| VOC Removal | Extracts residual solvents/by-products | Stabilizes material & chemical purity |

| Moisture Extraction | Removes trace moisture from matrix | Prevents oxidative degradation |

| High Vacuum | Lowers boiling point of volatiles | Avoids thermal damage to polymer |

| Pre-Vulcanization | Eliminates trapped gases | Prevents bubbles, voids, and pinholes |

| Density Control | Ensures a uniform, solid matrix | Optimizes mechanical & electrical properties |

Elevate Your Polymer Processing with KINTEK Precision

Don't let bubbles and pinhole defects compromise your material integrity. At KINTEK, we understand that high-performance Vinyl Methyl Phenyl Polysiloxane (VMPPS) requires meticulous thermal management. Backed by expert R&D and manufacturing, we offer a comprehensive range of Vacuum Drying Ovens, Muffle, Tube, and CVD systems tailored for lab and industrial high-temperature applications.

Whether you need standard equipment or a fully customizable solution to meet unique synthesis requirements, KINTEK provides the reliability and precision your research demands.

Contact us today to find the perfect vacuum system for your lab!

Visual Guide

References

- Ao Liu, Chaocan Zhang. A High-Temperature-Resistant and Conductive Flexible Silicone Rubber with High Phenyl Content Based on Silver-Coated Glass Fibers. DOI: 10.3390/polym17091187

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Induction Melting Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- Why is a vacuum oven essential for the degassing treatment of composite luminescent films? Ensure Optical Integrity

- How does high-temperature vacuum annealing affect GdFeCo thin films? Unlock Superior Magnetic Control

- What role does a high-temperature vacuum furnace play in the desilication of biomass? Achieve Ultra-High Purity Carbon

- What factors are crucial for successful vacuum brazing? Master Cleanliness, Joint Design, and Thermal Control

- What are the operational benefits of multi-chamber vacuum furnaces? Boost Throughput and Cut Costs

- How does a horizontal vacuum furnace handle different part sizes? Optimize Loading for Uniform Heating

- What are the advantages of a mesh belt brazing furnace vs vacuum? Optimize High-Volume Stainless Steel Production

- Why is a vacuum required for sulfur gas-phase diffusion? Boost Se-ZnS/HSC Cathode Sulfur Loading to 68.2 wt.%