The use of a vacuum arc furnace is strictly mandatory for preparing Fe60Co10-xNi15Cr15Six alloys to ensure the material retains its intended chemical composition and structural integrity. This equipment provides the dual capability of generating extreme melting temperatures while maintaining a high-vacuum or inert environment, which is the only reliable way to prevent oxidative contamination and force the atomic-scale mixing of these specific five elements.

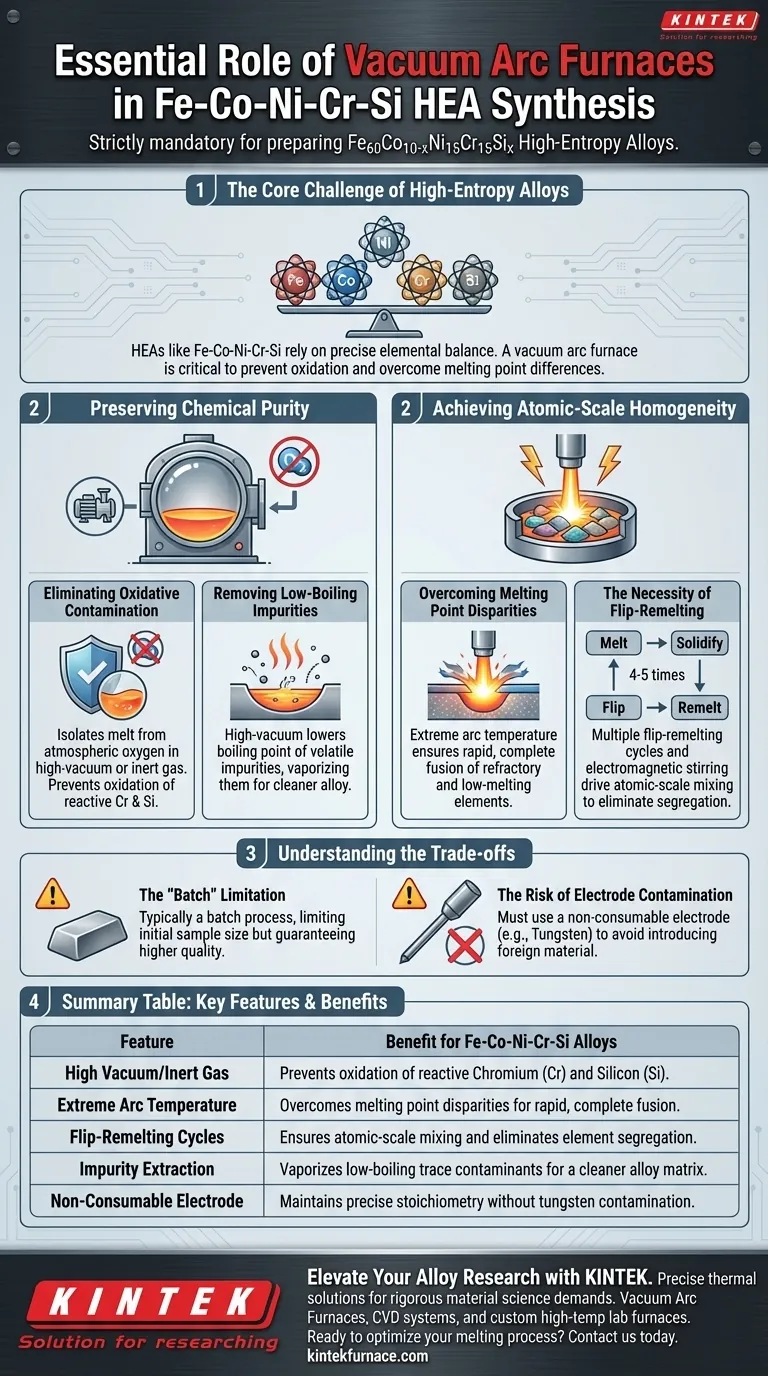

The Core Challenge of High-Entropy Alloys

High-Entropy Alloys (HEAs) like the Fe-Co-Ni-Cr-Si system rely on the precise balance of multiple principal elements. The vacuum arc furnace is critical because it prevents the oxidation of reactive components and overcomes significant differences in melting points to achieve a chemically uniform ingot.

Preserving Chemical Purity

To achieve the specific stoichiometry of Fe60Co10-xNi15Cr15Six, you must eliminate environmental variables that alter the alloy's composition during the liquid phase.

Eliminating Oxidative Contamination

The primary function of the vacuum arc furnace is to isolate the melt from atmospheric oxygen. Elements within this alloy system—particularly Chromium (Cr) and Silicon (Si)—are prone to oxidation at high temperatures.

By operating in a high-vacuum environment (or under ultra-pure argon), the furnace prevents active elements from reacting with oxygen. This ensures that the final ingot maintains the precise ratios of the raw materials, rather than losing mass to slag or oxide formation.

Removing Low-Boiling Impurities

Raw metallic materials often contain volatile impurities that can degrade the mechanical properties of the final alloy.

The high-vacuum environment lowers the boiling point of these unwanted trace contaminants. As the arc generates intense heat, these impurities vaporize and are effectively extracted from the melt, resulting in a cleaner, higher-purity alloy matrix.

Achieving Atomic-Scale Homogeneity

Simply melting the metals is not enough; they must be thoroughly mixed at the atomic level. This is difficult in HEAs due to the density and melting point variations between elements like Iron (Fe) and Silicon (Si).

Overcoming Melting Point Disparities

The vacuum arc furnace utilizes an electric arc to generate localized, extreme heat. This capability is essential for rapidly melting high-melting-point elements alongside those with lower melting points.

This rapid, high-energy melting ensures that refractory components are fully fused into the liquid pool before lower-melting elements have a chance to segregate or evaporate disproportionately.

The Necessity of Flip-Remelting

A single melting pass rarely results in a uniform distribution of five distinct elements. The standard protocol for this equipment involves multiple flip-remelting cycles.

The ingot is melted, allowed to solidify, flipped over, and remelted. This process, often combined with electromagnetic stirring inherent to the arc process, drives the atomic-scale mixing required to eliminate segregation. It ensures that the Silicon and Chromium are evenly distributed throughout the Iron-Cobalt-Nickel matrix.

Understanding the Trade-offs

While the vacuum arc furnace is the superior choice for purity and homogeneity, it introduces specific process constraints that must be managed.

The "Batch" Limitation

Vacuum arc melting is typically a batch process, often resulting in smaller "button" or ingot sizes compared to continuous casting methods. This limits the size of the initial sample but guarantees higher quality for research and precision applications.

The Risk of Electrode Contamination

It is critical to utilize a non-consumable electrode (typically Tungsten) for this process.

If the electrode degrades, it can introduce foreign material into the alloy, ruining the precise chemical balance of the HEA. The equipment setup must be rigorously checked to ensure the electrode design prevents this cross-contamination.

Making the Right Choice for Your Goal

To maximize the quality of your Fe60Co10-xNi15Cr15Six alloy, tailor your process parameters to your specific quality requirements.

- If your primary focus is Compositional Accuracy: Ensure the chamber undergoes multiple vacuum-purge cycles followed by an ultra-pure argon backfill to protect the Chromium and Silicon content.

- If your primary focus is Microstructural Uniformity: Do not settle for a single pass; implement a protocol of at least 4-5 flip-remelting cycles to guarantee the complete elimination of segregation.

Ultimately, the vacuum arc furnace is the gatekeeper of quality for this alloy, transforming a mix of raw metals into a cohesive, high-performance material.

Summary Table:

| Feature | Benefit for Fe-Co-Ni-Cr-Si Alloys |

|---|---|

| High Vacuum/Inert Gas | Prevents oxidation of reactive Chromium (Cr) and Silicon (Si) |

| Extreme Arc Temperature | Overcomes melting point disparities for rapid, complete fusion |

| Flip-Remelting Cycles | Ensures atomic-scale mixing and eliminates element segregation |

| Impurity Extraction | Vaporizes low-boiling trace contaminants for a cleaner alloy matrix |

| Non-Consumable Electrode | Maintains precise stoichiometry without tungsten contamination |

Elevate Your Alloy Research with KINTEK

Precise high-entropy alloy synthesis demands equipment that leaves no room for error. KINTEK provides industry-leading thermal solutions—from Vacuum Arc Furnaces to advanced CVD systems and customizable high-temp lab furnaces—designed to meet the rigorous demands of material science.

Backed by expert R&D and world-class manufacturing, our systems ensure your materials achieve the chemical purity and structural integrity required for breakthrough results.

Ready to optimize your melting process? Contact us today to discuss your unique project needs with our technical specialists.

Visual Guide

References

- Wenqiang Li, Fushan Li. Effect of Si Addition on Structure and Corrosion Resistance of FeCoNiCr High-Entropy Alloy Coating. DOI: 10.3390/ma18010072

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What factors should be considered when selecting a crucible for an induction-heated vacuum furnace? Ensure High-Purity Melts and Efficiency

- What are the operational features of an IGBT induction melting furnace? Achieve Faster, Smarter, and More Efficient Metal Melting

- What is the role of a vacuum induction furnace in CuNiSiCrCoTiNbx synthesis? Ensure Purity & Homogeneity

- What materials and specifications are typically used in vacuum casting? Master High-Fidelity Prototyping with PU Resins

- What are the advantages of using a VIM furnace to control residual oxygen pressure? Achieve Superior Metal Uniformity

- What is the disadvantage of an induction furnace? Its Core Limitation in Metal Refining

- Why is a vacuum induction melting furnace required for microalloyed steel ingots? Ensure Experimental Precision

- What are some common applications of induction furnace heating? Achieve Fast, Precise, and Clean Thermal Processing