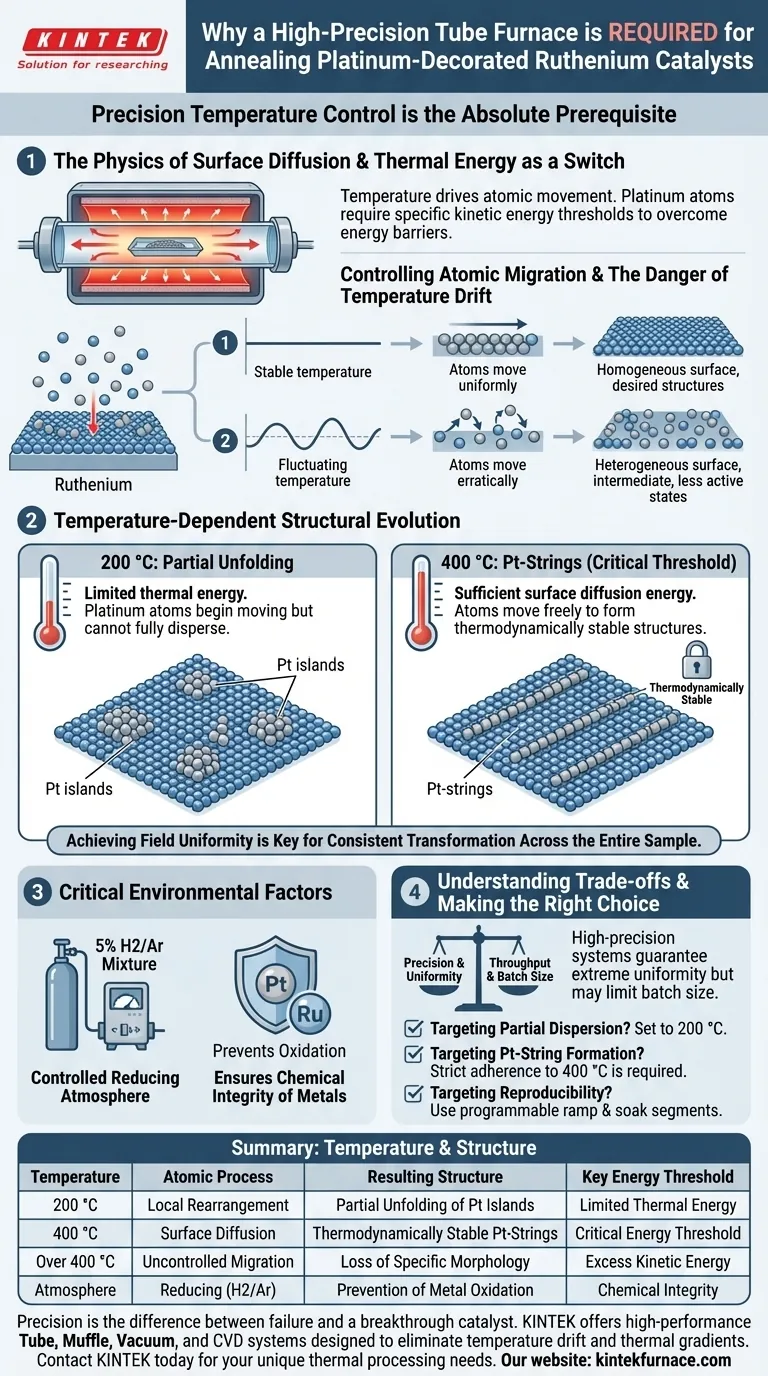

Precision temperature control is the absolute prerequisite for annealing platinum-decorated ruthenium catalysts because the physical arrangement of platinum atoms is dictated by exact thermal energy thresholds. A high-precision tube furnace is required to provide a stable thermal environment that drives specific surface diffusion processes without the interference of temperature drift.

The morphology of platinum on a ruthenium surface changes distinctively at specific temperature points. Without a high-precision control system to maintain these exact setpoints, you cannot reliably trigger the formation of thermodynamically stable structures like Pt-strings.

The Physics of Surface Diffusion

Thermal Energy as a Switch

Temperature is not merely a background condition in this process; it is the primary driver of atomic movement. Platinum atoms require specific amounts of kinetic energy to overcome the energy barriers binding them to their initial positions.

Controlling Atomic Migration

The goal of annealing is to manipulate how platinum atoms migrate across the ruthenium substrate. A tube furnace with a high-precision controller ensures that the energy supplied corresponds exactly to the activation energy required for the desired diffusion, rather than a random or fluctuating amount.

The Danger of Temperature Drift

If the temperature drifts even slightly, the diffusion rate changes unpredictably. This results in a heterogeneous surface where some areas have evolved into the desired structure while others remain in an intermediate, less active state.

Temperature-Dependent Structural Evolution

The 200 °C Threshold: Partial Unfolding

At lower temperatures, specifically around 200 °C, the thermal energy provided is limited. At this stage, platinum atoms have enough energy to begin moving but not enough to fully disperse.

This results in the partial unfolding of platinum islands. The atoms rearrange locally but do not yet possess the energy to traverse the surface distances required for more complex structures.

The 400 °C Transformation: Pt-Strings

When the temperature is raised to 400 °C, the system crosses a critical energy threshold. The platinum atoms acquire sufficient surface diffusion energy to move freely across the ruthenium lattice.

This specific energy level allows the atoms to settle into a thermodynamically stable configuration. Instead of isolated islands, they form continuous atomic chain structures known as Pt-strings.

Achieving Field Uniformity

The formation of Pt-strings requires the entire sample to experience 400 °C simultaneously. A high-quality tube furnace provides superior thermal field uniformity, ensuring that the catalyst at the edge of the sample boat undergoes the same morphological transformation as the catalyst in the center.

Critical Environmental Factors

Controlled Reducing Atmosphere

Beyond temperature, the chemical environment is vital. Tube furnaces allow for the introduction of a controlled reducing atmosphere, such as a 5% H2/Ar mixture.

Preventing Oxidation

While temperature drives diffusion, the atmosphere ensures the chemical integrity of the metals. Maintaining a precise reducing environment prevents oxidation during the high-temperature annealing process, ensuring the final catalyst retains its metallic character.

Understanding the Trade-offs

Precision vs. Throughput

High-precision tube furnaces often require smaller heating zones to guarantee extreme uniformity. This limits the batch size of the catalyst you can produce at one time compared to industrial, lower-precision ovens.

Hysteresis and Overshoot

Standard controllers may overshoot the target temperature during ramp-up, potentially providing too much energy too quickly. High-precision systems utilize advanced algorithms (like PID control) to eliminate overshoot, but they require careful tuning to match the thermal mass of the load.

Making the Right Choice for Your Goal

To maximize the performance of your platinum-decorated ruthenium catalysts, you must align your equipment settings with your specific morphological targets.

- If your primary focus is Partial Dispersion: Set your furnace to 200 °C to achieve the partial unfolding of platinum islands without triggering full migration.

- If your primary focus is Pt-String Formation: strict adherence to 400 °C is required to provide the exact diffusion energy needed for thermodynamically stable atomic chains.

- If your primary focus is Reproducibility: Ensure your furnace offers programmable ramp and soak segments to standardize the thermal history of every batch.

Select a furnace that prioritizes thermal stability over heating speed to guarantee the consistent formation of high-performance catalytic structures.

Summary Table:

| Temperature | Atomic Process | Resulting Structure | Key Energy Threshold |

|---|---|---|---|

| 200 °C | Local rearrangement | Partial unfolding of Pt islands | Limited thermal energy |

| 400 °C | Surface diffusion | Thermodynamically stable Pt-strings | Critical energy threshold |

| Over 400 °C | Uncontrolled migration | Loss of specific morphology | Excess kinetic energy |

| Atmosphere | Reducing (H2/Ar) | Prevention of metal oxidation | Chemical integrity |

Precision is the difference between a failed experiment and a breakthrough catalyst. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Vacuum, and CVD systems designed to eliminate temperature drift and thermal gradients. Whether you are targeting Pt-string formation or complex material synthesis, our customizable lab high-temp furnaces provide the stability your research demands. Contact KINTEK today to discuss your unique thermal processing needs.

Visual Guide

References

- Qinyu Li, Richard D. Tilley. How the Arrangement of Platinum Atoms on Ruthenium Nanoparticles Improves Hydrogen Evolution Activity. DOI: 10.1002/adma.202509610

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is an inert gas delivery system critical for a tube furnace? Engineering High-Performance Biochar

- What is the purpose of performing thermal annealing in vacuum-sealed glass tubes for nickel oxide films?

- What are the benefits of using an alumina tube furnace? Achieve Pure, High-Temp Material Processing

- What role does a high-temperature tube furnace play in the synthesis of Sr3Al2O6? Achieve 1300°C Phase Purity

- Why is a tube furnace essential for the reduction treatment of Y-NiMo/MoO2-x? Master Precision Synthesis

- Why is a controlled nitrogen atmosphere essential during the high-temperature processing of biomass in a tube furnace?

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- How does a tube furnace generate high temperatures for heat treatment? Discover Precision Heating Solutions