A symmetric assembly structure is critically necessary in the hot rolling of titanium-steel clad plates to counteract the inherent mechanical differences between the two metals. Because titanium and steel exhibit significantly different yield strengths and elongation rates, rolling them without a balanced, symmetric setup results in uneven deformation and severe bending.

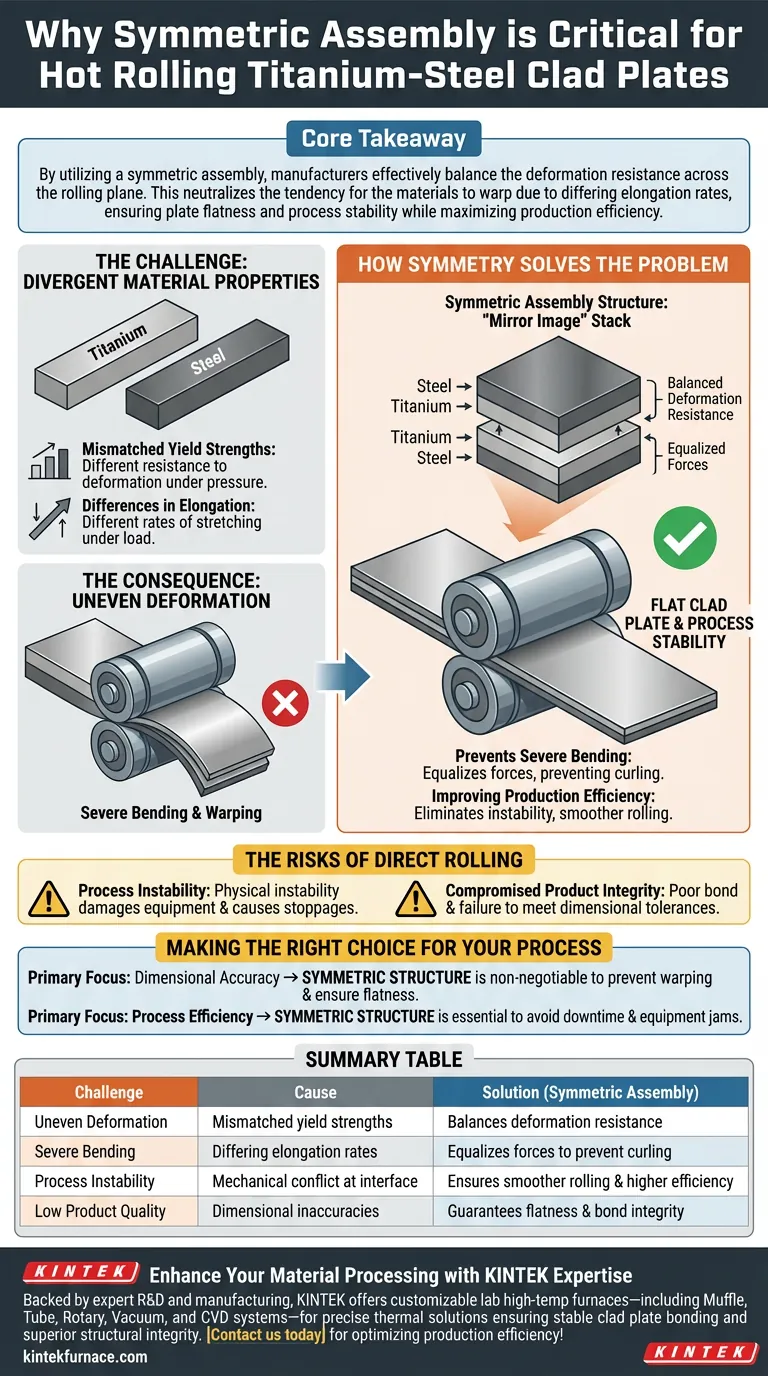

Core Takeaway By utilizing a symmetric assembly, manufacturers effectively balance the deformation resistance across the rolling plane. This neutralizes the tendency for the materials to warp due to differing elongation rates, ensuring plate flatness and process stability while maximizing production efficiency.

The Challenge: Divergent Material Properties

Mismatched Yield Strengths

Titanium and steel are fundamentally different materials with distinct yield strengths. When subjected to the immense pressure of hot rolling, they do not yield or deform under the exact same force.

Differences in Elongation

Similarly, these metals possess different elongation rates. Under the same rolling load, one material will naturally want to stretch further or faster than the other.

The Consequence: Uneven Deformation

If these materials are rolled directly without a symmetric setup, these disparities create a mechanical conflict. The material that stretches less restricts the one that stretches more, leading to immediate uneven deformation across the interface.

How Symmetry Solves the Problem

Balancing Deformation Resistance

A symmetric assembly structure essentially creates a "mirror image" stack of materials. This configuration balances the deformation resistance exerted by the titanium and steel layers on the rolling mill.

Preventing Severe Bending

By equalizing the forces on the top and bottom of the assembly, symmetry prevents the clad plate from curling. Without this balance, the internal stress caused by the elongation mismatch would force the plate to experience severe bending, rendering it unusable.

Improving Production Efficiency

Symmetry does more than just protect the product; it streamlines the process. By eliminating the instability associated with warping and curling, the rolling process becomes smoother, significantly improving production efficiency.

The Risks of Direct Rolling

Process Instability

Attempting to roll titanium and steel without a symmetric structure introduces chaos into the rolling line. The physical instability caused by the warping plates can damage equipment or force production stoppages.

Compromised Product Integrity

The uneven deformation does not just bend the plate; it compromises the bond and the structural integrity of the final product. A non-symmetric approach risks producing clad plates that fail to meet flatness and dimensional tolerances.

Making the Right Choice for Your Process

Depending on your specific manufacturing priorities, here is how you should view the requirement for symmetry:

- If your primary focus is Dimensional Accuracy: A symmetric structure is non-negotiable to prevent warping and ensure the final clad plate remains flat.

- If your primary focus is Process Efficiency: Utilizing symmetry is essential to avoid downtime caused by material instability or equipment jams during the rolling pass.

Symmetry is not merely a design choice; it is a mechanical necessity for neutralizing the physical disparities between titanium and steel.

Summary Table:

| Challenge | Cause | Solution (Symmetric Assembly) |

|---|---|---|

| Uneven Deformation | Mismatched yield strengths | Balances deformation resistance |

| Severe Bending | Differing elongation rates | Equalizes forces to prevent curling |

| Process Instability | Mechanical conflict at interface | Ensures smoother rolling and higher efficiency |

| Low Product Quality | Dimensional inaccuracies | Guarantees flatness and bond integrity |

Enhance Your Material Processing with KINTEK Expertise

Don't let material disparities compromise your product quality. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to meet your unique titanium-steel processing needs.

Our advanced thermal solutions ensure the precise temperature control required for stable clad plate bonding and superior structural integrity. Contact us today to discover how our specialized equipment can optimize your production efficiency and solve your toughest manufacturing challenges!

Visual Guide

References

- Juan Pu, Yunxia Chen. Effect of Heat Treatment Temperature on the Microstructure and Properties of Titanium-Clad Steel Plate Prepared by Vacuum Hot Rolling. DOI: 10.3390/coatings14091096

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is the significance of the dual-crucible arrangement in NCMCS sulfidation? Enhance Purity and Control

- How does the temperature capability of continuous furnaces benefit industrial processes? Boost High-Volume Production with Extreme Heat

- What is the importance of using a vacuum drying oven for MoS2/rGO battery electrodes? Maximize Battery Performance

- Why Use the Modified Two-Temperature Synthesis for ZnGeP2? Ensure Safety and Material Quality

- What role does high-temperature calcination play in the purification of volcanic ash? Achieve Ultra-Pure Silica Results

- What is the purpose of using a furnace at 500 °C for catalyst support pretreatment? Optimize Purity and Performance

- What is the objective of placing TC4 titanium alloy parts on asbestos pads? Control Stress and Thermal Shock

- What is the role of a rapid thermal processing furnace in CdO/CdS/ZnO fabrication? Achieve High-Quality Heterojunctions