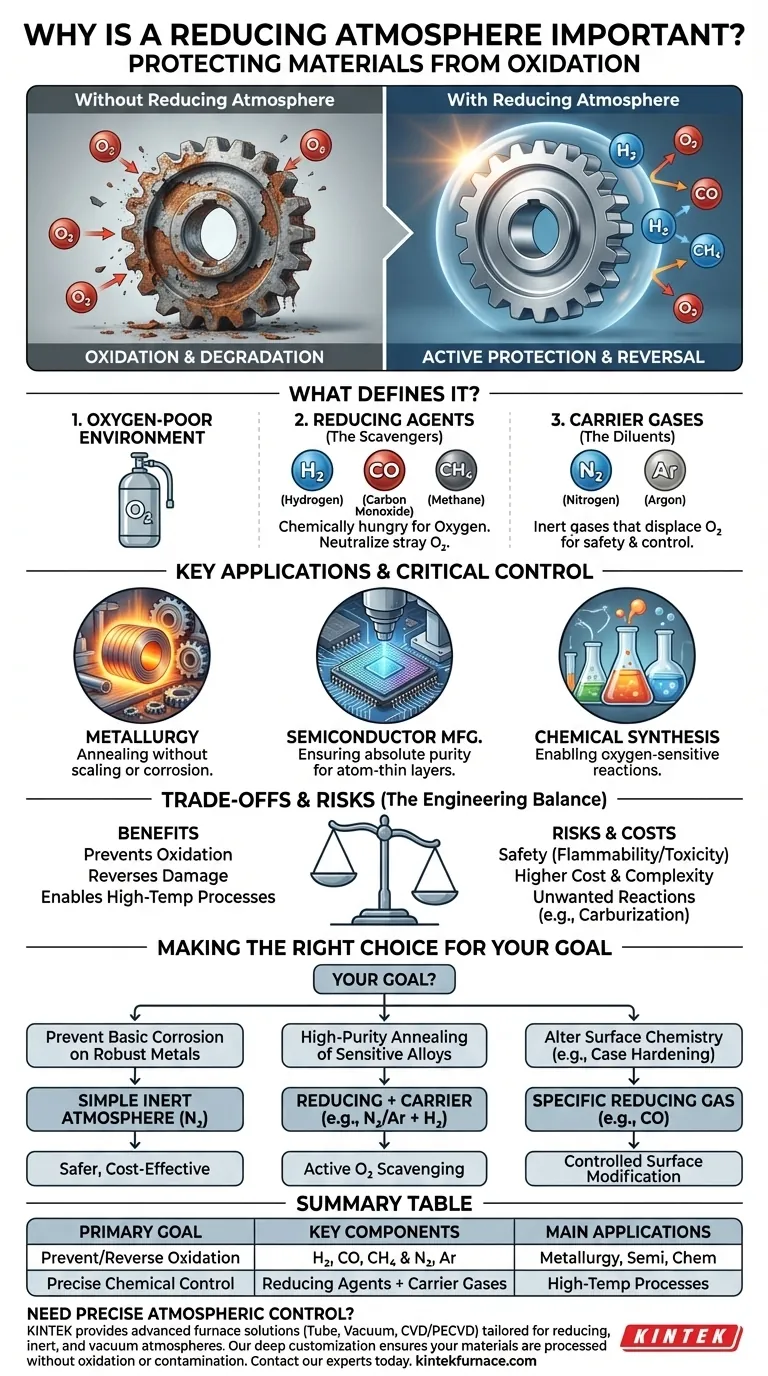

At its core, a reducing atmosphere is important because it provides an environment that actively prevents and can even reverse oxidation. This control is critical for high-temperature processes like metal treatment, where oxygen would otherwise cause corrosion, weaken the material, or compromise its surface integrity.

The true value of a reducing atmosphere lies in its ability to protect materials from chemical degradation. By removing oxygen and introducing gases that readily react with it, you can heat, treat, and manipulate materials without the unwanted side effects of oxidation.

What Defines a Reducing Atmosphere?

A reducing atmosphere is fundamentally an oxygen-poor environment. However, it's more than just the absence of oxygen; it's an active system designed to scavenge any oxygen that is present.

The Absence of Oxidizers

The primary characteristic is the near-total lack of oxygen and other oxidizing gases. The goal is to create an environment where oxidation simply cannot occur.

The Presence of Reducing Agents

To achieve this, the atmosphere is filled with reducing gases. These are gases that are chemically "hungry" for oxygen atoms. Common examples include hydrogen (H₂), carbon monoxide (CO), and methane (CH₄).

Think of these gases as security guards for your material. If any stray oxygen molecule enters the environment, a reducing gas molecule will immediately react with it, neutralizing the threat before it can harm the material's surface.

The Role of Carrier Gases

Often, these potent reducing gases are used in small, diluted amounts for safety and control. They are mixed with an inert carrier gas, most commonly nitrogen (N₂) or argon (Ar), which displaces the oxygen without reacting with the material itself.

Key Applications: Where This Control Is Critical

Preventing oxidation is essential across numerous industrial and scientific fields. The higher the process temperature, the more aggressive oxidation becomes, and the more vital a reducing atmosphere is.

Metallurgy and Metal Treatment

This is the most common application. During annealing, metals are heated to relieve internal stresses and improve ductility. Performing this in a normal atmosphere would cause severe scaling and corrosion. A reducing atmosphere allows the metal to be treated without being damaged.

Semiconductor Manufacturing

The creation of microchips involves depositing and etching incredibly thin layers of material onto silicon wafers. Even a minuscule, single-atom layer of unintended oxide can ruin a device. Reducing atmospheres are essential for maintaining the absolute purity required in these processes.

Chemical Synthesis

Many chemical reactions require an oxygen-free environment to produce the desired compound. The presence of oxygen could lead to unwanted byproducts or cause the reaction to fail entirely.

Understanding the Trade-offs and Risks

While powerful, creating a reducing atmosphere is not without its challenges. It is a deliberate engineering choice with specific costs and dangers.

Safety and Flammability

The most effective reducing gases—hydrogen, carbon monoxide, and methane—are highly flammable or explosive. CO is also extremely toxic. Handling these gases requires rigorous safety protocols, ventilation, and monitoring systems.

Cost and Complexity

Maintaining a controlled atmosphere is more expensive than simply using ambient air. It requires specialized furnaces, sealed chambers, a continuous supply of high-purity gases, and sophisticated control systems to manage gas composition and flow.

Unwanted Material Reactions

The reducing gases themselves can sometimes react with the workpiece in undesirable ways. For instance, gases containing carbon (like CO or CH₄) can introduce carbon into the surface of steel at high temperatures, a process called carburization, which may alter the metal's properties in a way that is not intended.

Making the Right Choice for Your Goal

The specific composition of a controlled atmosphere depends entirely on the material being processed and the desired outcome.

- If your primary focus is preventing basic corrosion on robust metals: A simple inert atmosphere of nitrogen might be sufficient and is safer and more cost-effective.

- If your primary focus is high-purity annealing of sensitive alloys: A nitrogen or argon atmosphere with a small percentage of hydrogen is the standard for actively scavenging all traces of oxygen.

- If your primary focus is altering surface chemistry (like case hardening): You would intentionally use a specific reducing gas, like carbon monoxide, to react with and modify the material's surface in a controlled way.

Ultimately, using a reducing atmosphere is about exercising precise chemical control to protect or modify a material, ensuring the final product meets its exact specifications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Actively prevent or reverse oxidation by removing oxygen. |

| Key Components | Reducing gases (H₂, CO, CH₄) and inert carrier gases (N₂, Ar). |

| Main Applications | Metallurgy (annealing), Semiconductor Manufacturing, Chemical Synthesis. |

| Key Considerations | Safety (flammability/toxicity), Cost, and potential for unwanted reactions (e.g., carburization). |

Need precise atmospheric control for your high-temperature processes?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced furnace solutions tailored for reducing, inert, and vacuum atmospheres. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements, ensuring your materials are processed without oxidation or contamination.

Contact our experts today to discuss how we can design a furnace solution to protect your materials and achieve your exact specifications.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment