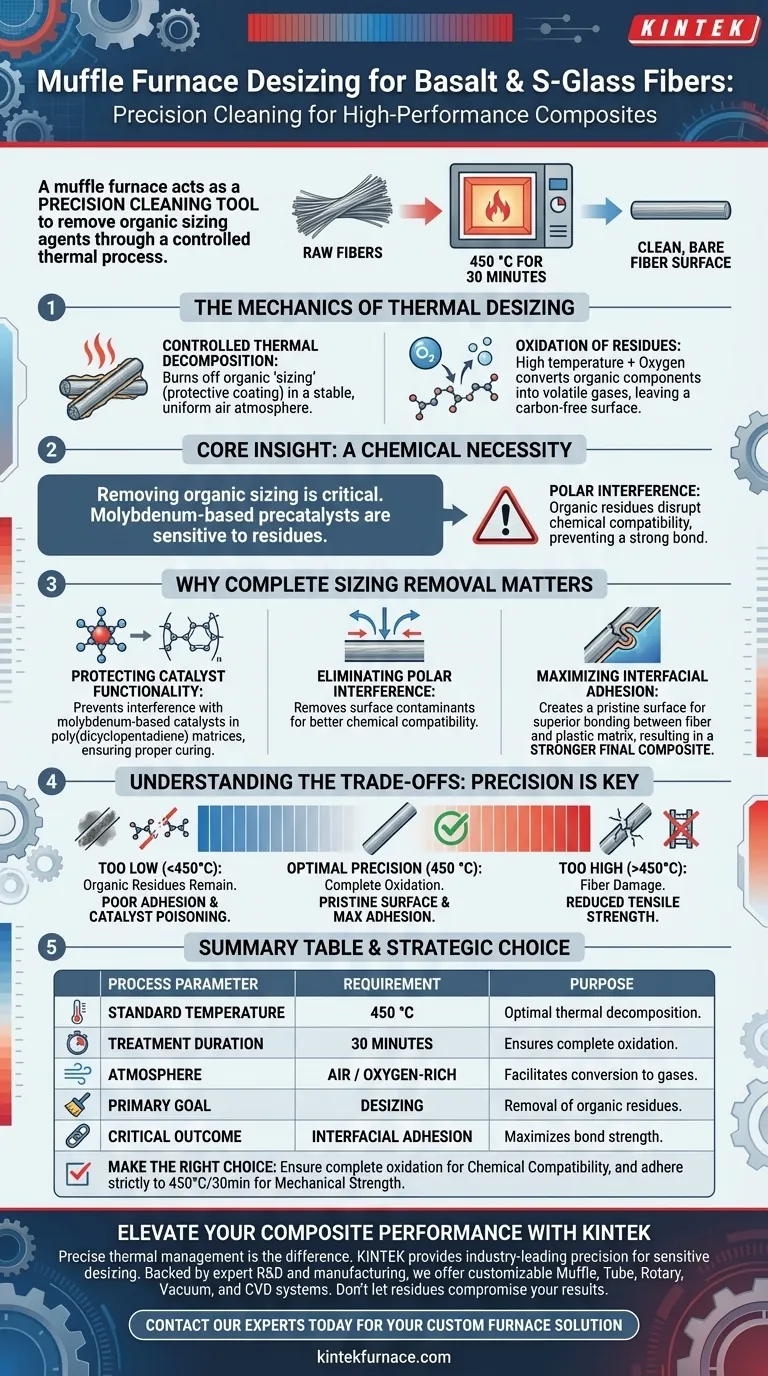

A muffle furnace acts as a precision cleaning tool used to strip organic sizing agents from basalt or S-glass fibers through a controlled thermal process. By subjecting the fibers to a high-temperature air environment—specifically around 450 °C for 30 minutes—the furnace ensures the complete thermal decomposition and oxidation of the carbonaceous coatings applied during fiber manufacturing.

Core Insight: The removal of organic sizing is not merely a cleaning step; it is a chemical necessity. Molybdenum-based precatalysts used in specific composite matrices are highly sensitive to organic residues, and failing to remove them causes polar interference that compromises the final material's structural integrity.

The Mechanics of Thermal Desizing

Controlled Thermal Decomposition

The muffle furnace provides a stable, uniform environment essential for thermal desizing. This process burns off the organic "sizing" (a protective coating applied during fiber production) by exposing it to consistent heat in an air atmosphere.

Oxidation of Residues

The combination of high temperature and oxygen facilitates the complete oxidation of organic components. This transforms the coating into volatile gases, leaving behind a clean, bare fiber surface free of carbonaceous contaminants.

Why Complete Sizing Removal Matters

Protecting Catalyst Functionality

In specific composite preparations involving a poly(dicyclopentadiene) matrix, the chemical reaction relies on molybdenum-based precatalysts.

These catalysts are chemically sensitive to the organic sizing agents found on raw fibers. If the sizing is left intact, it interferes with the catalyst's operation, inhibiting the curing process.

Eliminating Polar Interference

Organic residues on the fiber surface can create polar interference. This phenomenon disrupts the chemical compatibility between the fiber and the resin system, preventing a strong bond from forming.

Maximizing Interfacial Adhesion

The mechanical strength of a composite depends heavily on the interface—the point where the fiber meets the plastic matrix. By using a muffle furnace to create a pristine surface, you significantly improve the interfacial adhesion between the basalt or S-glass fibers and the matrix, resulting in a stronger final composite.

Understanding the Trade-offs

The Importance of Temperature Precision

While heat is the cleaning agent, precision is the safety mechanism. A muffle furnace is required because it offers exact temperature control.

Risks of Improper Heating

If the temperature is too low or the time too short, organic residues remain, leading to poor adhesion and catalyst poisoning. Conversely, significantly exceeding the standard 450 °C threshold risks damaging the physical structure of the glass fibers themselves, reducing their tensile strength before they are even molded.

Making the Right Choice for Your Goal

To ensure high-performance composites, apply the desizing process based on your specific chemical requirements:

- If your primary focus is Chemical Compatibility: Ensure complete oxidation of organics to prevent poisoning molybdenum-based precatalysts.

- If your primary focus is Mechanical Strength: Strictly adhere to the 450 °C / 30-minute parameter to maximize interfacial adhesion without thermally degrading the fiber.

Reliable composite performance begins with a pristine interface, achievable only through precise thermal management.

Summary Table:

| Process Parameter | Requirement | Purpose |

|---|---|---|

| Standard Temperature | 450 °C | Optimal thermal decomposition without fiber damage |

| Treatment Duration | 30 Minutes | Ensures complete oxidation of carbonaceous coatings |

| Atmosphere | Air / Oxygen-rich | Facilitates conversion of sizing to volatile gases |

| Primary Goal | Desizing | Removal of organic residues to prevent polar interference |

| Critical Outcome | Interfacial Adhesion | Maximizes bond strength between fiber and matrix |

Elevate Your Composite Performance with KINTEK

Precise thermal management is the difference between a compromised material and a high-performance composite. KINTEK provides the industry-leading precision required for sensitive desizing treatments. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific laboratory or industrial needs.

Don't let organic residues compromise your catalyst functionality or interfacial adhesion. Partner with KINTEK to ensure your basalt and S-glass fibers are processed with the exact temperature stability your research demands.

Contact our experts today to find your custom furnace solution!

Visual Guide

References

- Benjamin R. Kordes, Michael R. Buchmeiser. Ring‐Opening Metathesis Polymerization‐Derived Poly(dicyclopentadiene)/Fiber Composites Using Latent Pre‐Catalysts. DOI: 10.1002/mame.202300367

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What reaction environment must a muffle furnace or tube furnace provide for g-C3N4? Master Thermal Polymerization

- Which industries benefit from the use of muffle furnaces? Essential Applications Across 8 Key Sectors

- What materials are recommended for muffle furnace construction? Optimize for High-Temp Performance and Safety

- What comprises the working chamber of a box type resistance furnace? Discover the Core Components for Efficient High-Temp Operations

- What role does a muffle furnace play in the preparation of expanded graphite? Achieve Maximum Expansion through Thermal Shock

- What maintenance practices are recommended for muffle furnaces? Ensure Longevity and Precision in Your Lab

- Why is heating tube spacing critical in muffle furnace design? Master Thermal Uniformity for Superior Processing

- What temperature range can muffle furnaces typically achieve? Find the Right Furnace for Your Lab Needs