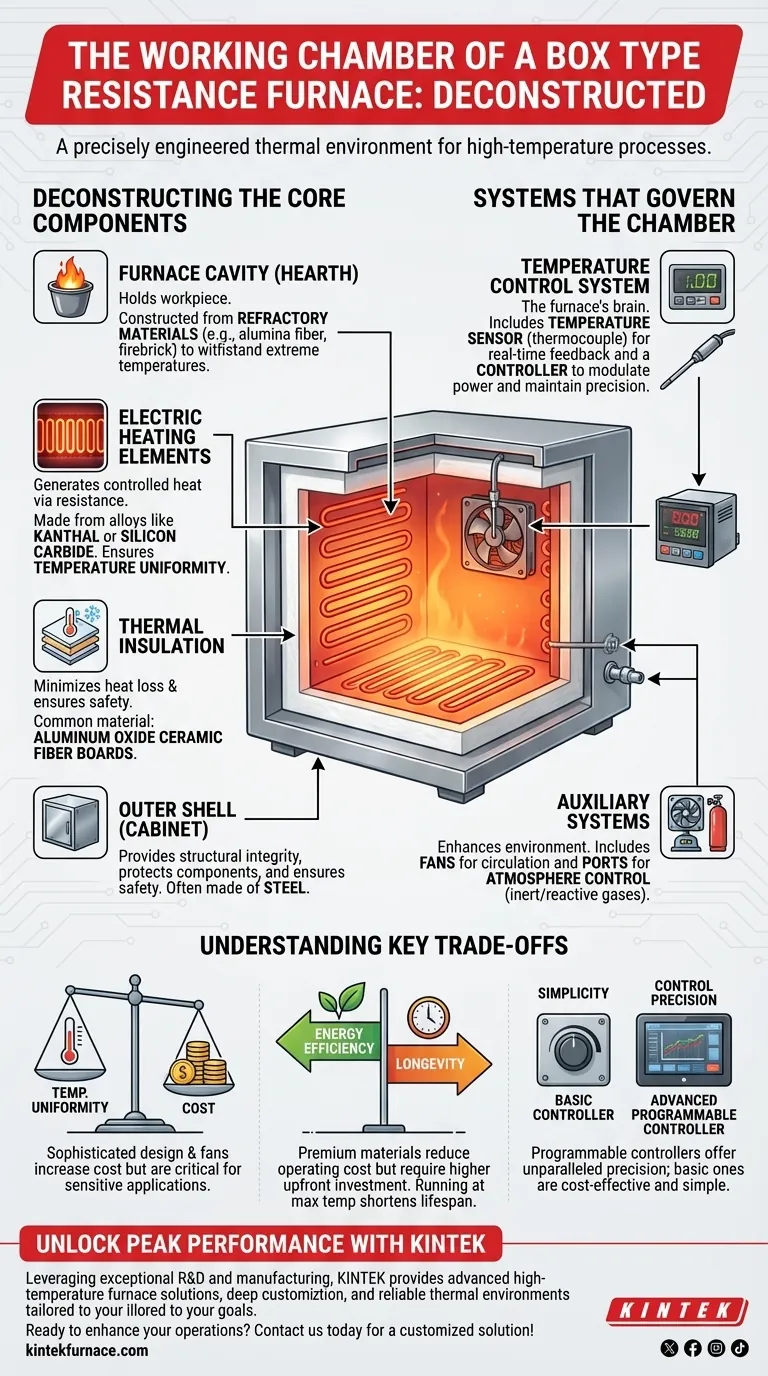

The working chamber of a box type resistance furnace is a precisely engineered thermal environment. At its core, the chamber consists of a furnace cavity, or hearth, constructed from refractory materials designed to withstand extreme temperatures. Within this cavity are the electric heating elements that generate the heat, and the entire assembly is wrapped in high-performance thermal insulation to maintain efficiency and safety.

Understanding the components of the working chamber is simple, but appreciating how they function as a system is critical. The chamber is not just a hot box; it is a balanced system where materials, energy sources, and controls work in concert to create a stable, uniform, and efficient high-temperature environment.

Deconstructing the Core Components

A box furnace's performance is a direct result of the quality and integration of its core components. Each part serves a distinct and vital function.

The Furnace Cavity (Hearth)

The hearth is the active area where the workpiece is placed. It is constructed from refractory materials, such as high-purity alumina fiber or firebrick.

These materials are chosen for their ability to endure extreme thermal shock and high temperatures without degrading, ensuring a clean and stable environment for processes like sintering or analysis.

Electric Heating Elements

These are the source of thermal energy. They are typically resistance wires or rods made from alloys like Kanthal (iron-chromium-aluminum) or more advanced materials like silicon carbide for higher temperatures.

When electricity passes through these elements, their resistance generates intense, controlled heat. Their placement around the chamber is a critical design factor that directly dictates temperature uniformity.

Thermal Insulation

Positioned between the hot furnace cavity and the cool outer shell, thermal insulation is the key to efficiency. Materials like aluminum oxide ceramic fiber boards are commonly used.

The primary role of insulation is to minimize heat loss to the surrounding environment. This not only drastically reduces energy consumption but also ensures the furnace's external surface remains at a safe temperature for operators.

The Outer Shell (Cabinet)

The entire assembly is housed within a sturdy metal shell, often made of steel. This cabinet provides structural integrity, protects the delicate internal components from physical damage, and serves as the final layer of safety for personnel.

The Systems That Govern the Chamber

The physical chamber is only half of the equation. Sophisticated control systems are required to manage the thermal environment with the precision required for modern processes.

The Temperature Control System

This is the furnace's brain. It consists of two main parts: a temperature sensor (typically a thermocouple) placed inside the chamber and a controller.

The sensor provides real-time temperature feedback to the controller, which then modulates the power sent to the heating elements to precisely maintain the desired temperature setpoint. This ensures process repeatability and accuracy.

Auxiliary Systems

Depending on the application, furnaces may include auxiliary equipment to further refine the internal environment. This can include fans to improve air circulation and temperature uniformity or ports for introducing inert or reactive gases for atmosphere control.

Understanding the Key Trade-offs

Selecting or operating a furnace involves balancing performance characteristics. Understanding these trade-offs is essential for making an informed decision.

Temperature Uniformity vs. Cost

Achieving a highly uniform temperature across the entire chamber requires sophisticated heating element design, strategic placement, and potentially circulation fans. While critical for sensitive applications, these features increase the furnace's initial cost.

Energy Efficiency vs. Longevity

High-performance insulation and energy-efficient heating elements reduce long-term operational costs by minimizing electricity consumption. However, these premium materials often come with a higher upfront investment. Likewise, running a furnace at its maximum rated temperature for extended periods can shorten the lifespan of heating elements.

Control Precision vs. Simplicity

An advanced, programmable temperature controller offers unparalleled precision for complex heating cycles. For simpler, single-setpoint applications, a basic controller is more cost-effective and easier to operate, but lacks the flexibility for more demanding processes.

Making the Right Choice for Your Goal

Understanding how these components interact empowers you to select a furnace that aligns with your specific technical and financial requirements.

- If your primary focus is high-precision lab work (e.g., analysis, ceramic sintering): Prioritize a furnace with documented temperature uniformity, an advanced programmable controller, and a clean, non-reactive hearth material.

- If your primary focus is general heat treatment or industrial production: Focus on a robust design with durable heating elements and high-quality thermal insulation to ensure reliability and energy efficiency over long operational hours.

- If your primary focus is minimizing total cost of ownership: Evaluate the furnace's energy efficiency and the expected lifespan and replacement cost of its heating elements and insulation.

A thorough understanding of the working chamber's design is the first step toward ensuring reliable, efficient, and safe high-temperature operations.

Summary Table:

| Component | Function | Key Materials |

|---|---|---|

| Furnace Cavity (Hearth) | Holds workpiece, withstands high temperatures | Refractory materials (e.g., alumina fiber, firebrick) |

| Electric Heating Elements | Generates controlled heat | Resistance alloys (e.g., Kanthal, silicon carbide) |

| Thermal Insulation | Minimizes heat loss, ensures safety | Aluminum oxide ceramic fiber boards |

| Outer Shell (Cabinet) | Provides structural integrity and safety | Steel |

| Temperature Control System | Maintains precise temperature | Thermocouple sensor, controller |

| Auxiliary Systems | Enhances environment (e.g., uniformity, atmosphere) | Fans, gas ports |

Unlock Peak Performance in Your High-Temperature Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on high-precision lab work, industrial production, or minimizing total cost of ownership, we deliver reliable, efficient, and safe thermal environments tailored to your goals.

Ready to enhance your operations? Contact us today for a customized solution!

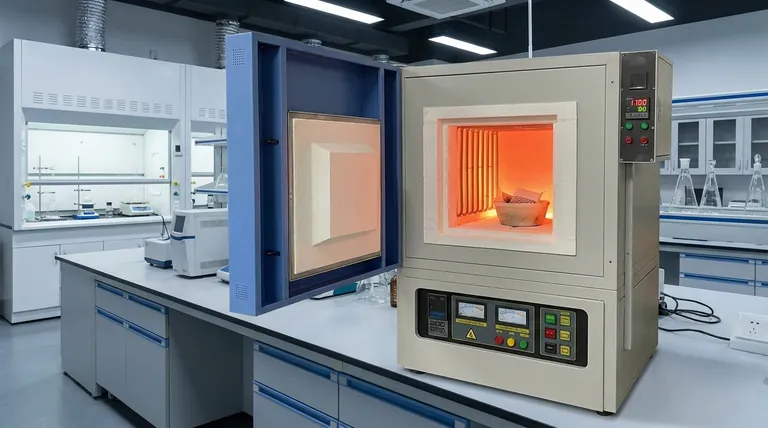

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- Why is a high-temperature muffle furnace typically selected for annealing? Achieve Optimal Ceramic Performance

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- How is an industrial-grade ashing furnace utilized in 3D-printed bioactive glass? Master Debinding & Sintering

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes