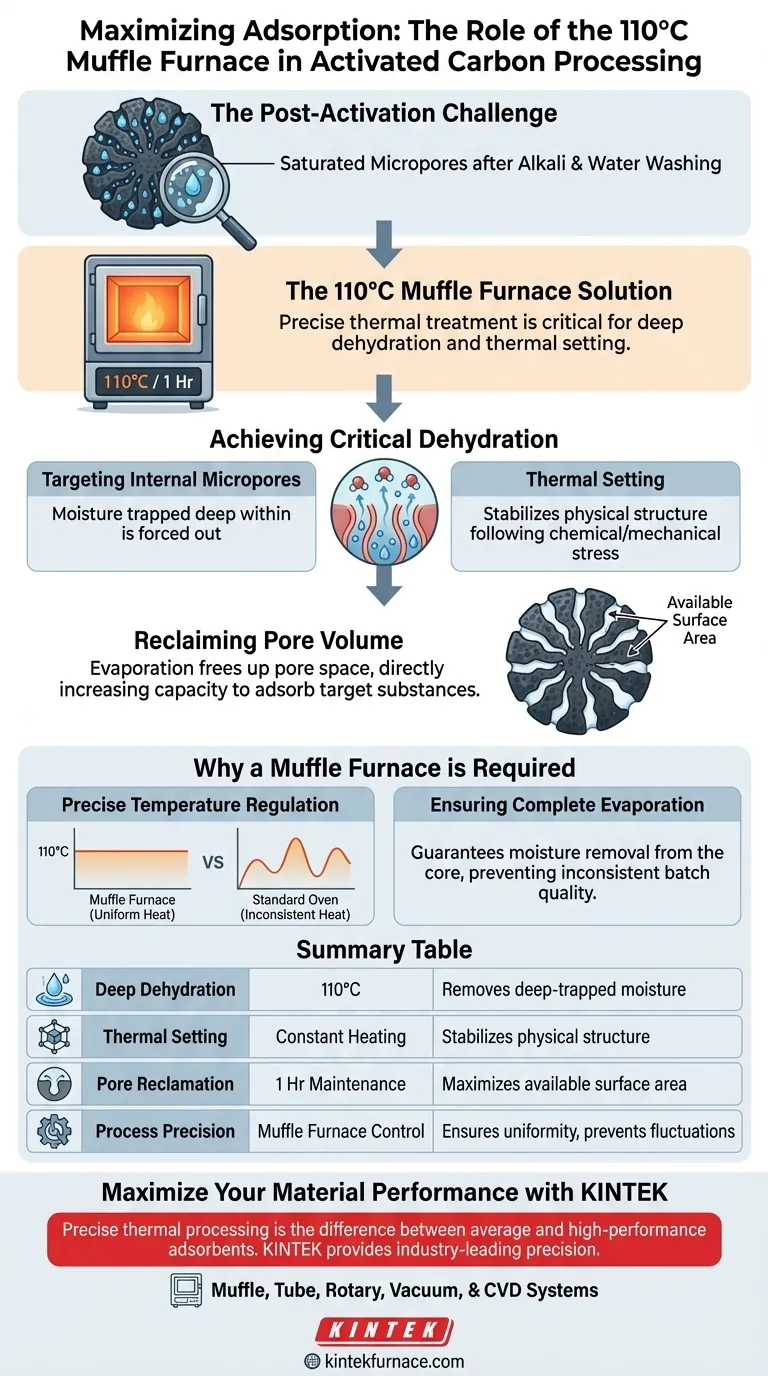

The primary purpose of using a muffle furnace for a second heat treatment is to achieve deep dehydration and thermal setting of the material. After activated carbon undergoes alkali and water washing, it retains significant moisture within its complex internal structure. Maintaining the material at 110°C for one hour ensures this residual water is completely evaporated, which is essential for reclaiming the pore volume required for effective adsorption.

The washing process cleans the carbon but leaves it saturated; the final heat treatment effectively "clears" the pores. By precisely maintaining 110°C, you maximize available surface area and optimize the material's final adsorption performance.

The Role of Post-Activation Processing

Recovering from the Washing Phase

Before this heating stage, the activated carbon undergoes washing with alkali and water. While necessary for removing chemical residues and ash, this process leaves the carbon saturated with moisture.

The Necessity of Thermal Setting

The primary reference highlights that this step provides "thermal setting." This stabilizes the physical structure of the carbon following the mechanical and chemical stress of the washing process.

Achieving Critical Dehydration

Targeting Internal Micropores

Surface moisture evaporates relatively quickly. However, moisture trapped within the deep, internal micropores requires more energy to dislodge.

The Significance of 110°C

Setting the temperature to 110°C is critical because it sits just above the boiling point of water. This ensures the thermodynamic conditions necessary to force water out of the smallest capillary structures are met.

Reclaiming Pore Volume

Water molecules physically occupy the space within the carbon's pores. Until this water is removed, those pores cannot trap other contaminants. Evaporation releases this "pore volume," directly increasing the material's capacity to adsorb target substances.

Why a Muffle Furnace is Required

Precise Temperature Regulation

The reference specifies the need for "precise temperature control." A muffle furnace provides a stable, uniform heat environment that standard drying ovens may not achieve.

Ensuring Complete Evaporation

Fluctuations in temperature could lead to incomplete drying. The muffle furnace maintains the steady 110°C needed to guarantee that moisture is removed from the core of the material, not just the surface.

Understanding the Trade-offs

The Risk of Incomplete Drying

If the temperature drops below 110°C or the duration is less than one hour, deep dehydration will fail. This leaves residual moisture in the micropores, resulting in a final product with subpar adsorption metrics.

Energy and Time Investment

This step adds time and energy costs to the production cycle. However, skipping it renders the previous activation steps less effective, as the created pores would remain blocked by water.

Ensuring Quality in Final Production

To maximize the efficiency of your activated carbon, strict adherence to this final processing step is essential.

- If your primary focus is maximum adsorption capacity: Ensure the full one-hour duration is respected to guarantee that internal micropores are completely cleared of water molecules.

- If your primary focus is process reliability: Utilize the precise control of a muffle furnace to prevent temperature fluctuations that could lead to inconsistent batch quality.

Precise dehydration is the final, critical bridge between a washed raw material and a high-performance adsorbent product.

Summary Table:

| Process Objective | Temperature & Duration | Key Benefit |

|---|---|---|

| Deep Dehydration | 110°C | Removes moisture trapped in deep internal micropores |

| Thermal Setting | Constant Heating | Stabilizes physical structure after chemical washing |

| Pore Reclamation | 1 Hour Maintenance | Maximizes available surface area for target adsorption |

| Process Precision | Muffle Furnace Control | Ensures uniform heating and prevents batch inconsistency |

Maximize Your Material Performance with KINTEK

Precise thermal processing is the difference between average and high-performance adsorbents. KINTEK provides the industry-leading precision required for critical dehydration and thermal setting. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial high-temperature requirements.

Don't let inconsistent heat compromise your results. Contact KINTEK today to discover how our high-precision furnace solutions can optimize your production quality and research accuracy.

Visual Guide

References

- Jolantje Latupeirissa, Muliana Muliana. CHARACTERISATION OF ACTIVATED CARBON FROM WHITE SNAPPER SCALES (Lates calcarife) WASTE. DOI: 10.30872/jkm.v21i2.1292

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of a high-temperature calcination furnace in preparing ultra-fine oxide nanopowders? Master Purity

- What are the typical applications of a muffle furnace? Achieve Precision and Purity in High-Temp Processes

- Why is a muffle furnace used for 1350°C Ti-Al-Nb heat treatment? Optimize Alloy Plasticity and Stress Relief

- What are the main structural components of a muffle furnace? Discover the Engineered System for Contamination-Free Heating

- What is the purpose of a muffle furnace? Achieve Contamination-Free High-Temperature Processing

- How does an electric laboratory furnace contribute to the glass melting process? Precision Thermal Solutions

- What safety measures should be observed around the muffle furnace? Essential Protocols for Safe Operation

- What are the advantages of using an Infrared Rapid Heating Furnace? Capture Transient Atomic Migrations in Steel