To ensure the successful synthesis of NiWO4 monomer powders, a laboratory high-temperature tube furnace is required to provide a uniform thermal environment at approximately 900 degrees Celsius. This precise heating is necessary to induce the phase transformation of hydrothermal intermediates, removing residual solvents and crystallizing the material into a highly ordered structure.

The tube furnace is not merely a heat source; it is a precision instrument that provides the stable thermal field necessary to guarantee the crystal quality and phase purity required for high-performance electrochemical applications.

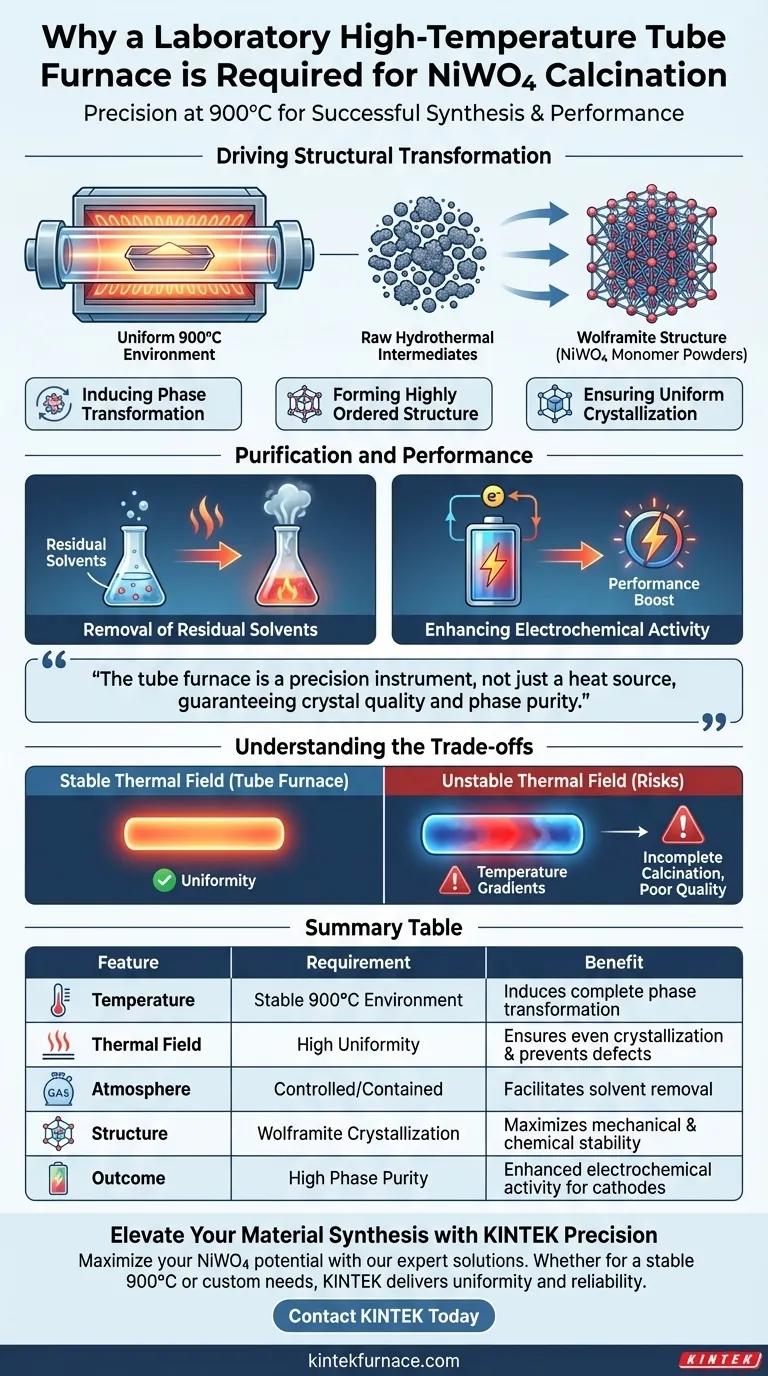

Driving Structural Transformation

Inducing Phase Transformation

Raw hydrothermal intermediates are not yet in a stable state for application. The tube furnace provides the sustained energy required to induce a complete phase transformation.

Forming the Wolframite Structure

At temperatures around 900 degrees Celsius, the material crystallizes into a highly ordered wolframite structure. This specific structural arrangement is critical for the material's mechanical and chemical stability.

Ensuring Uniform Crystallization

The defining feature of a tube furnace is its ability to maintain a uniform high-temperature environment. This uniformity ensures that crystallization occurs evenly throughout the powder sample, preventing structural defects.

Purification and Performance

Removal of Residual Solvents

The calcination process effectively purges the material of volatile impurities. The heat drives off residual solvents left over from the synthesis process, which creates a cleaner final product.

Enhancing Electrochemical Activity

The ultimate goal of this calcination is to maximize the material's utility as a cathode. The superior crystal quality and phase purity achieved through this stable thermal processing directly correlate to enhanced electrochemical activity.

Understanding the Trade-offs

The Necessity of Thermal Stability

While other heating methods exist, they often lack the stability of a tube furnace. Without a stable thermal field, you risk creating temperature gradients within the sample.

Risks of Incomplete Calcination

If the temperature fluctuates or fails to reach the target 900 degrees Celsius uniformly, phase transformation may be incomplete. This results in poor crystal quality and reduced performance in the final application.

Making the Right Choice for Your Goal

To maximize the potential of your NiWO4 powders, consider your specific performance targets when configuring your calcination process.

- If your primary focus is Electrochemical Activity: Ensure your furnace creates a highly stable 900°C environment to maximize the order of the wolframite structure.

- If your primary focus is Phase Purity: Rely on the uniform heat distribution to fully eliminate residual solvents and prevent mixed-phase formation.

Precision in thermal processing is the deciding factor between a mediocre powder and a high-performance cathode material.

Summary Table:

| Feature | Requirement for NiWO4 Calcination | Benefit to Final Product |

|---|---|---|

| Temperature | Stable 900°C Environment | Induces complete phase transformation |

| Thermal Field | High Uniformity | Ensures even crystallization and prevents defects |

| Atmosphere | Controlled/Contained | Facilitates removal of residual solvents |

| Structure | Wolframite Crystallization | Maximizes mechanical and chemical stability |

| Outcome | High Phase Purity | Enhanced electrochemical activity for cathodes |

Elevate Your Material Synthesis with KINTEK Precision

Maximize the potential of your NiWO4 powders with thermal solutions designed for excellence. KINTEK provides industry-leading laboratory high-temperature furnaces, including Tube, Muffle, Rotary, Vacuum, and CVD systems, all backed by expert R&D and manufacturing.

Whether you require a stable 900°C environment for wolframite structure formation or a customizable system for unique research needs, our furnaces deliver the uniformity and reliability necessary for high-performance electrochemical applications.

Ready to achieve superior crystal quality? Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Likai Deng, Shifa Wang. Advanced Electrochemical Performance of NiWO4/Graphene Oxide as Cathode Material for Zinc Ion Battery. DOI: 10.3390/en18082023

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key features of a Split Tube Furnace (Single Zone)? Unlock Easy Access and Uniform Heating

- How does a tube furnace facilitate the structural stabilization of lignin? Mastering Lignin-to-Carbon Transformation

- How does a vacuum tube nitriding system control the reaction environment? Precision Surface Hardening for AISI 304

- What essential experimental conditions does a laboratory horizontal tube furnace provide for wood chip pyrolysis?

- What is the primary function of a tube furnace? Achieve Precise Atmospheric Control for Material Processing

- What role does a tube furnace play in the high-temperature heat treatment stage of catalyst fabrication?

- What are the key features of high temperature tube furnaces? Unlock Precision for Material Science

- How does a Split Tube Furnace (Single Zone) operate? Unlock Easy Access and Uniform Heating