At its core, a single-zone split tube furnace is a high-temperature heating device defined by two primary characteristics. Its "split" nature comes from a tube chamber that is hinged to open along its length, providing exceptional access, while its "single zone" designation means it has one uniform area of controlled heat.

The key takeaway is that a single-zone split tube furnace prioritizes accessibility and simplicity. The split design is a significant quality-of-life feature for handling complex samples, while the single heating zone delivers straightforward, uniform thermal processing.

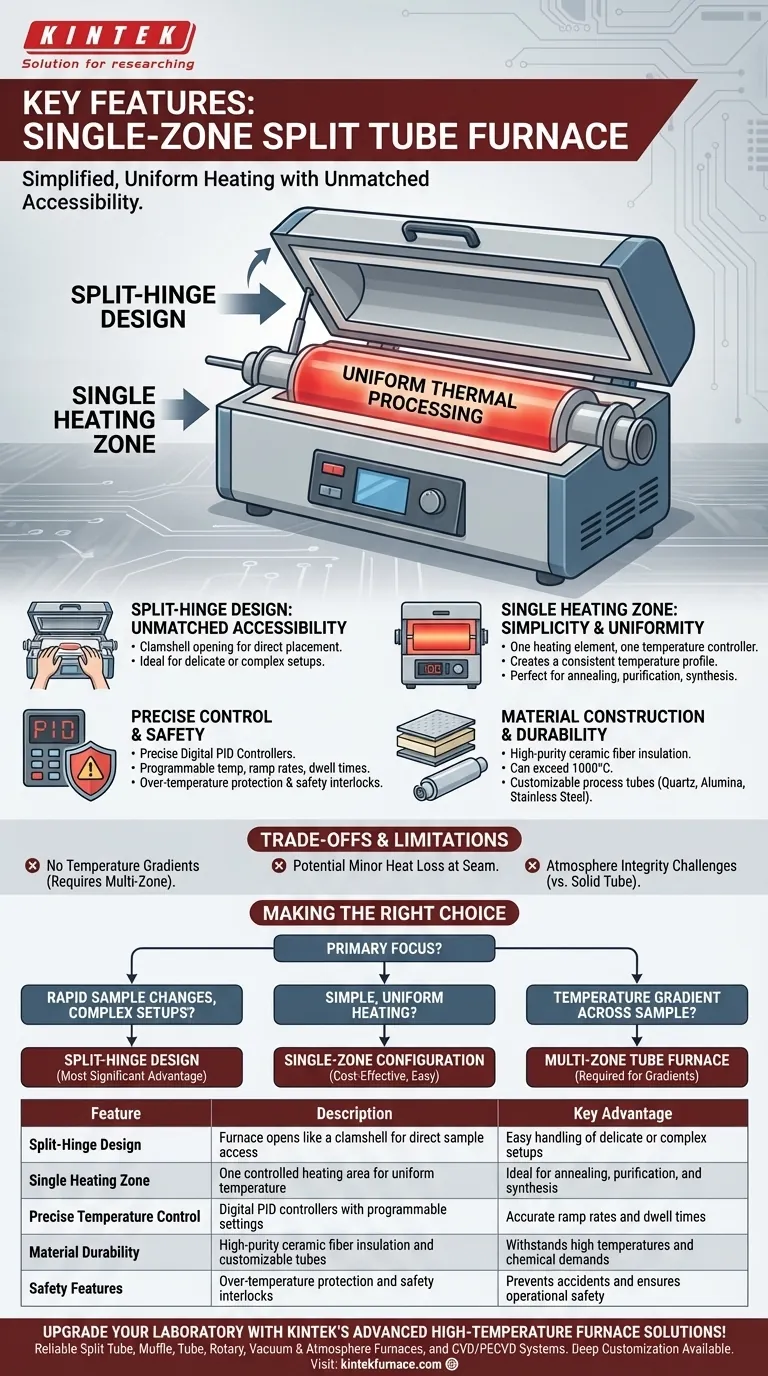

The Anatomy of a Single-Zone Split Tube Furnace

To understand if this furnace is the right tool for your work, it's essential to analyze its core design components and the specific advantages they provide.

The Split-Hinge Design: Unmatched Accessibility

The most distinctive feature is its split-hinge construction. The furnace body is built in two halves, connected by hinges, allowing it to open like a clamshell.

This design enables you to place and remove samples directly into the heating zone, rather than sliding them in from one end. This is invaluable for delicate samples or complex experimental setups with multiple probes and connections that cannot be easily threaded through a solid tube.

The Single Heating Zone: Simplicity and Uniformity

The term "single zone" signifies that the furnace has one heating element (or set of elements) governed by a single temperature controller.

This creates a single, consistent temperature profile along the central portion of the process tube. This is ideal for applications like annealing, purification, or synthesis where the entire sample needs to be exposed to the same temperature.

Precise Temperature Control and Safety

Modern split tube furnaces are equipped with precise digital PID controllers (Proportional-Integral-Derivative). These systems allow for accurate programming of temperature setpoints, ramp rates, and dwell times.

Essential safety features are also standard, including over-temperature protection that automatically cuts power if a set limit is exceeded and safety interlocks that may prevent the furnace from operating when open.

Material Construction and Durability

These furnaces are built from high-quality, heat-resistant materials. The insulation is typically made of high-purity ceramic fiber to minimize heat loss and allow for efficient performance at temperatures often exceeding 1000°C.

The process tube itself, which contains the sample, is a separate component and can be made from materials like quartz, alumina, or stainless steel, depending on the temperature and chemical requirements of your experiment.

Understanding the Trade-offs and Limitations

While powerful, this furnace design is not universally optimal. Understanding its inherent limitations is critical for making an informed decision.

Single Zone vs. Multi-Zone for Gradients

The primary limitation of a single-zone furnace is its inability to create a temperature gradient. If your process requires different parts of a sample to be at different temperatures simultaneously (e.g., for chemical vapor transport), you will need a multi-zone furnace.

Potential for Heat Loss

The seam where the two halves of the furnace meet can be a source of minor heat loss compared to a solid, non-split furnace. While modern designs minimize this, it can slightly impact maximum temperature efficiency and uniformity right at the edges of the zone.

Atmosphere Integrity Challenges

For applications requiring a high vacuum or a perfectly sealed inert atmosphere, the split design presents more potential leak points than a solid tube furnace. While they can be equipped for vacuum operation, achieving the highest levels of vacuum integrity may be more challenging.

Making the Right Choice for Your Process

Your specific experimental goal should dictate your choice of furnace.

- If your primary focus is rapid sample changes or complex setups: The accessibility of the split-hinge design is the most significant advantage and will save considerable time and effort.

- If your primary focus is simple, uniform heating of a sample: A single-zone configuration is cost-effective, easy to control, and perfectly suited for the task.

- If your primary focus is creating a temperature gradient across a sample: You must choose a multi-zone tube furnace, as a single-zone design cannot meet this requirement.

Ultimately, the single-zone split tube furnace is an exceptional tool for its intended purpose: providing simple, uniform heat with unparalleled ease of access.

Summary Table:

| Feature | Description | Key Advantage |

|---|---|---|

| Split-Hinge Design | Furnace opens like a clamshell for direct sample access | Easy handling of delicate or complex setups |

| Single Heating Zone | One controlled heating area for uniform temperature | Ideal for annealing, purification, and synthesis |

| Precise Temperature Control | Digital PID controllers with programmable settings | Accurate ramp rates and dwell times |

| Material Durability | High-purity ceramic fiber insulation and customizable tubes | Withstands high temperatures and chemical demands |

| Safety Features | Over-temperature protection and safety interlocks | Prevents accidents and ensures operational safety |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable split tube furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for enhanced efficiency and results. Contact us today to discuss how our furnaces can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety