At its core, a single-zone split tube furnace operates by using electrical resistance to generate heat within a chamber that can be opened along its length. This hinged "split" design allows for easy placement of a process tube, while the "single zone" designation means a single controller manages the heating elements to create one uniform temperature environment for the sample inside.

The primary advantage of this design is its combination of accessibility and simplicity. The split body allows you to place or inspect samples without disassembling your entire setup, while the single heating zone is ideal for straightforward processes requiring consistent, uniform heat.

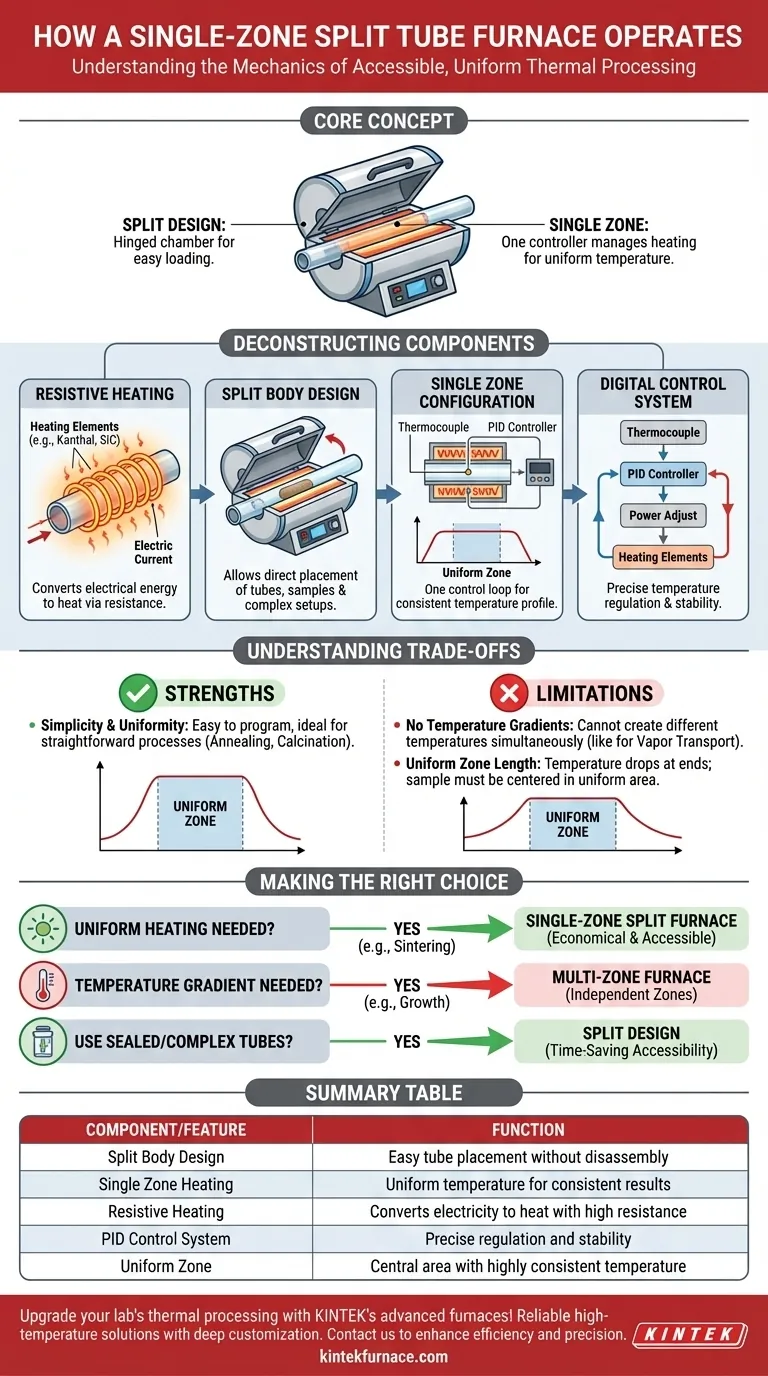

Deconstructing the Core Components

To understand its operation, we must look at how its key parts work together to create a controlled thermal environment. Each component serves a distinct and critical function.

The Principle of Resistive Heating

The furnace generates heat through resistive heating. An electric current is passed through specialized heating elements, which are made of materials with high electrical resistance, such as Kanthal (an iron-chromium-aluminum alloy) or Silicon Carbide (SiC).

As the elements resist the flow of electricity, they convert electrical energy into thermal energy, glowing hot and radiating heat inward towards the central process tube.

The 'Split' Body Design

The term "split tube" refers to the furnace's hinged body. The main insulated chamber is split into two halves, typically along the horizontal axis, allowing it to be opened and closed like a clamshell.

This design is a significant practical advantage. It allows operators to place a process tube with pre-loaded samples, sealed ends, or complex connections directly into the furnace without having to slide it in from one end.

The 'Single Zone' Configuration

A "single zone" furnace has one continuous set of heating elements managed by one temperature controller and one thermocouple. This creates a single, unified temperature profile along the heated length.

The goal is to produce a central area within the furnace—the "uniform zone"—where the temperature is highly consistent. For precise work, the sample must be placed within this specific area.

The Digital Control System

Modern furnaces rely on a PID (Proportional-Integral-Derivative) controller for precise temperature regulation. A thermocouple placed near the heating elements measures the real-time temperature.

The controller constantly compares this reading to the desired setpoint. It then intelligently adjusts the power sent to the heating elements to maintain the target temperature with minimal overshoot or fluctuation, ensuring process accuracy and repeatability.

Understanding the Trade-offs

While effective, the single-zone split design has specific strengths and limitations that make it suitable for some applications but not others.

Strength: Simplicity and Uniformity

The primary strength is operational simplicity. With only one temperature to set and monitor, these furnaces are straightforward to program and run.

This makes them an excellent, cost-effective choice for many common thermal processes, including annealing, tempering, calcination, and material synthesis, where the entire sample requires a single, stable temperature.

Limitation: Lack of Temperature Gradients

The single-zone design cannot create a temperature gradient, where different sections of the tube are held at different temperatures simultaneously.

Processes like chemical vapor transport, which rely on a temperature difference to sublimate a material in one zone and deposit it in another, require a multi-zone furnace.

Limitation: Uniform Zone Length

It is a common misconception that the entire heated length of the furnace is perfectly uniform in temperature. In reality, the temperature naturally drops off near the ends of the furnace chamber.

The truly uniform zone is a shorter section in the center of the furnace. For accurate results, it is critical to know the length of this zone for your specific model and ensure your sample is positioned entirely within it.

Making the Right Choice for Your Process

Selecting the correct furnace requires matching its capabilities to your specific experimental or production goals.

- If your primary focus is uniform heating (annealing, calcination, synthesis): A single-zone split tube furnace is an excellent and economical choice that offers great accessibility.

- If your process requires a temperature gradient (vapor transport, specialized reactions): You must use a multi-zone furnace with at least two independent heating zones.

- If you frequently use sealed tubes or complex experimental setups: The accessibility of the "split" design will save significant time and effort compared to a non-split (solid) tube furnace.

Ultimately, understanding the function of each design feature empowers you to select the precise tool for your specific thermal processing needs.

Summary Table:

| Component/Feature | Function |

|---|---|

| Split Body Design | Allows easy placement of process tubes without disassembly |

| Single Zone Heating | Provides uniform temperature for consistent sample heating |

| Resistive Heating | Converts electrical energy to heat using high-resistance elements |

| PID Control System | Ensures precise temperature regulation and stability |

| Uniform Zone | Central area with highly consistent temperature for accurate results |

Upgrade your lab's thermal processing with KINTEK's advanced split tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your efficiency and precision!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision