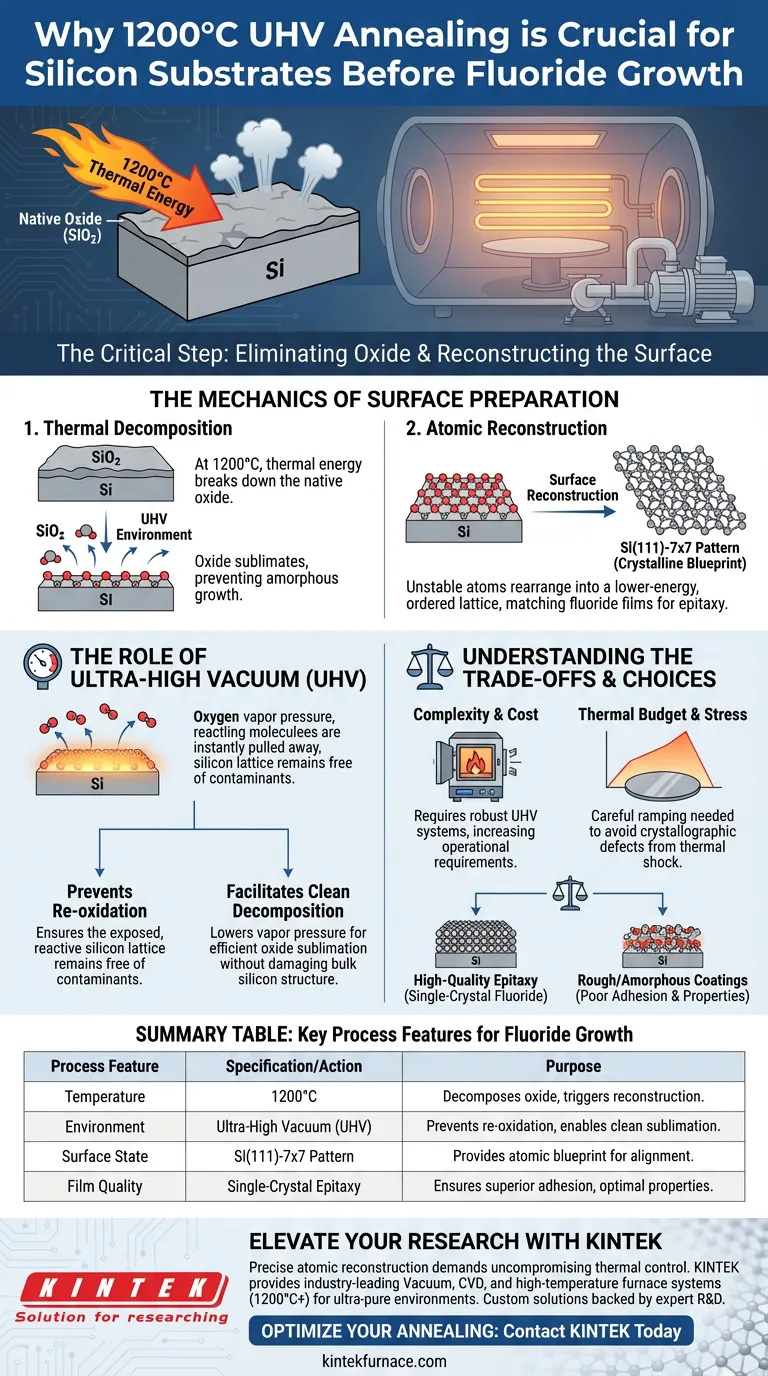

A high-temperature treatment at 1200°C is the critical preparation step required to completely eliminate the native oxide layer from a silicon substrate. This process utilizes thermal decomposition to strip away surface contaminants, exposing the pristine silicon atomic lattice underneath.

The process is not merely about cleaning; it is about architectural preparation. The 1200°C thermal treatment removes the oxide barrier to trigger surface reconstruction, specifically creating the Si(111)-7x7 pattern that serves as the necessary blueprint for high-quality epitaxial fluoride growth.

The Mechanics of Surface Preparation

Thermal Decomposition of Native Oxide

Silicon naturally forms a thin layer of silicon dioxide (native oxide) when exposed to air. This layer acts as a barrier to crystalline growth.

At 1200°C, the thermal energy is sufficient to decompose this oxide layer.

The oxide evaporates from the surface, leaving behind the pure silicon bulk. Without this step, subsequent fluoride layers would be deposited on an amorphous oxide surface rather than the crystalline silicon, preventing proper bonding.

Achieving Atomic Reconstruction

Once the oxide is removed, the surface atoms of the silicon are unstable and possess high energy.

To stabilize, the atoms rearrange themselves into a lower-energy structure known as surface reconstruction.

The primary reference notes that this specifically facilitates the formation of the Si(111)-7x7 reconstruction. This specific atomic arrangement establishes a foundation with a lattice structure that matches the fluoride thin films, enabling epitaxial (ordered) growth.

The Role of Ultra-High Vacuum (UHV)

Preventing Re-oxidation

Heating silicon to 1200°C in the presence of oxygen would be catastrophic; it would accelerate oxidation rather than remove it.

The ultra-high vacuum (UHV) environment is essential to ensure that once the oxygen leaves the surface, it is pumped away immediately.

This environment guarantees that the exposed, highly reactive silicon lattice remains free of contaminants during the annealing process.

Facilitating Clean Decomposition

The vacuum lowers the vapor pressure required for the oxide to sublime.

This allows the decomposition process to occur efficiently without requiring temperatures even higher than 1200°C, which could damage the bulk crystal structure of the silicon.

Understanding the Trade-offs

Equipment Complexity and Cost

Achieving 1200°C while maintaining an ultra-high vacuum requires specialized, robust equipment.

Standard annealing furnaces cannot withstand these conditions, necessitating the use of dedicated UHV systems which increases operational complexity and cost.

Thermal Budget and Stress

Subjecting a wafer to 1200°C introduces significant thermal energy.

While necessary for oxide removal, this thermal shock must be ramped carefully to avoid introducing slip lines or crystallographic defects into the deeper layers of the silicon substrate.

Making the Right Choice for Your Goal

The necessity of this high-temperature step depends entirely on your requirements for the final fluoride film quality.

- If your primary focus is High-Quality Epitaxy: You must perform the 1200°C UHV anneal to ensure a reconstructed Si(111)-7x7 surface, which is the only way to achieve a single-crystal fluoride film.

- If your primary focus is Rough/Amorphous Coatings: You might skip this step, but understand that the fluoride layer will not align with the silicon lattice and will likely have poor adhesion and electrical properties.

Ultimately, the 1200°C treatment is the non-negotiable gateway to atomic-level precision in silicon-fluoride heteroepitaxy.

Summary Table:

| Process Feature | Specification/Action | Purpose for Fluoride Growth |

|---|---|---|

| Temperature | 1200°C | Decomposes native oxide and triggers surface reconstruction |

| Environment | Ultra-High Vacuum (UHV) | Prevents re-oxidation and facilitates clean oxide sublimation |

| Surface State | Si(111)-7x7 Pattern | Provides the atomic blueprint for epitaxial alignment |

| Film Quality | Single-Crystal Epitaxy | Ensures superior adhesion and optimal electrical properties |

Elevate Your Material Research with KINTEK

Precise atomic reconstruction demands uncompromising thermal control. KINTEK provides industry-leading Vacuum, CVD, and high-temperature furnace systems engineered to reach 1200°C+ while maintaining the ultra-pure environments required for silicon substrate preparation.

Backed by expert R&D and precision manufacturing, our systems are fully customizable to meet your unique lab requirements—ensuring your epitaxial growth is built on a perfect foundation.

Ready to optimize your annealing process?

Contact KINTEK Today to Consult Our Experts

Visual Guide

References

- Thin Fluoride Insulators for Improved 2D Transistors: From Deposition Methods to Recent Applications. DOI: 10.1002/pssr.202500200

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- In what common configurations are graphite heating elements arranged in vacuum furnaces? Optimize for Uniform Heating

- What technical advantages do electric furnace systems offer for copper slag impoverishment? Maximize Your Metal Recovery

- Why is a vacuum oven necessary for polysilsesquioxane synthesis? Ensure Purity & Prevent Material Defects

- What are the advantages of using a vacuum heat treatment furnace? Precision Solution Treatment for 17-4PH Steel

- What role does a vacuum oven play in delta-MnO2 electrode processing? Stabilize and Protect Your Active Materials

- What is the typical working vacuum degree for most heat treatment vacuum furnaces? Optimize Your Process with the Right Vacuum Level

- What are the key benefits of using a vacuum furnace? Achieve Superior Material Purity and Control

- What is the function of a laboratory vacuum drying oven in W-Ni2P@NiFe LDH/NF preparation? Optimize Electrocatalysts