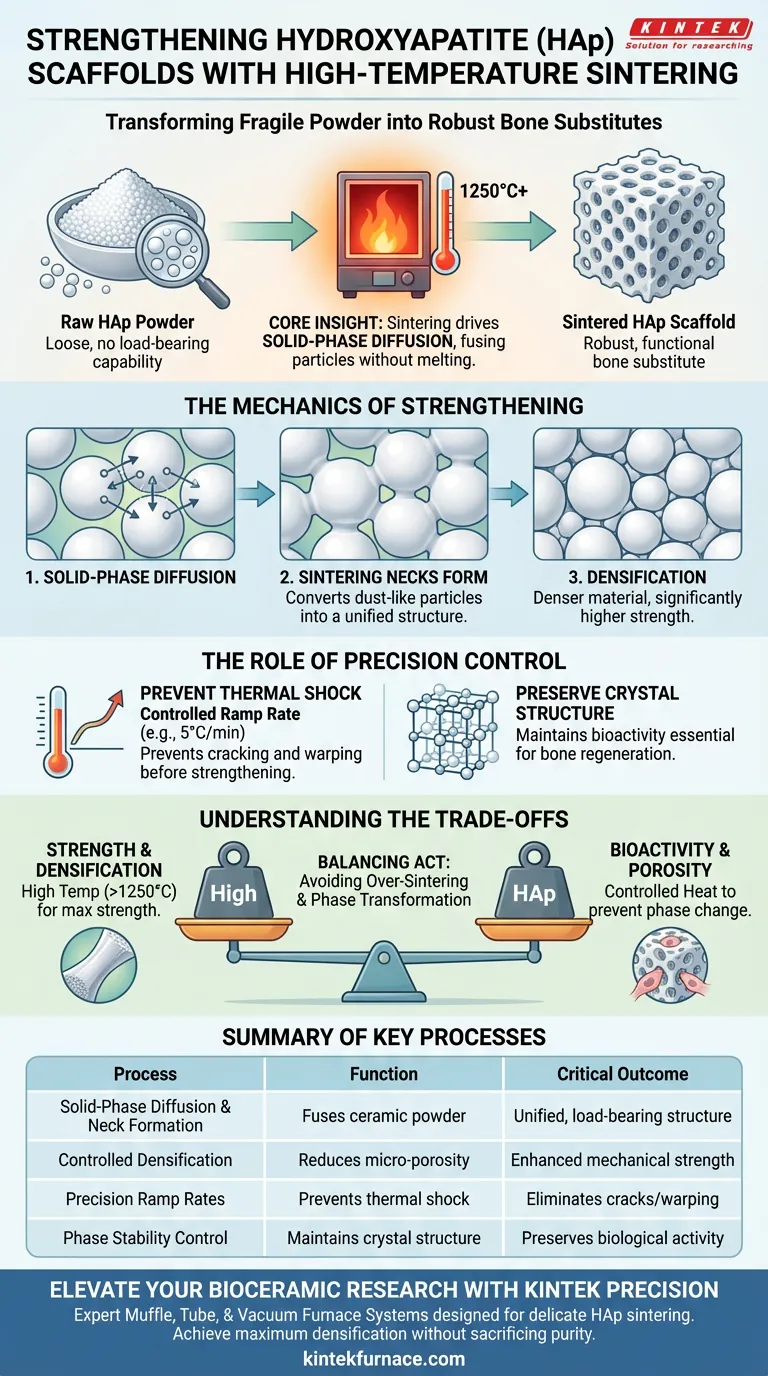

A high-temperature sintering furnace is the critical instrument for transforming fragile ceramic powder into a robust structural scaffold. Without this specific thermal processing, a hydroxyapatite (HAp) scaffold remains a loosely packed powder compact with no load-bearing capability. The furnace provides the extreme heat—often exceeding 1250°C—necessary to trigger the atomic bonding required for mechanical integrity.

The Core Insight Simply shaping hydroxyapatite into a scaffold form is not enough; it must be "fired" to become functional. The sintering furnace drives solid-phase diffusion, a process that fuses particles together to create high strength without melting the material, effectively balancing durability with biological compatibility.

The Mechanics of Strengthening

Facilitating Solid-Phase Diffusion

At the microscopic level, raw HAp scaffolds consist of individual ceramic particles touching one another but not physically bonded.

The high-temperature environment of the furnace initiates solid-phase diffusion. This causes atoms to move across the boundaries of the particles, fusing them together.

Forming Sintering Necks

As diffusion progresses, connection points known as sintering necks form between adjacent particles.

These necks grow in size, thickening the bond between particles. This is the primary mechanism that converts a collection of dust-like particles into a unified, rigid structure.

Achieving Densification

The ultimate goal of this process is densification. As sintering necks grow, the pores between individual particles shrink.

This results in a denser, more cohesive material. A densified scaffold possesses significantly higher mechanical strength, allowing it to withstand the physical stresses of implantation and bone support.

The Role of Precision Control

Preventing Thermal Shock

Raw heat is not sufficient; the application of heat must be carefully controlled.

A high-quality sintering furnace allows for precise ramp rates, such as 5 degrees Celsius per minute. This gradual increase prevents thermal shock, which could cause the ceramic scaffold to crack or warp before it fully strengthens.

Preserving Crystal Structure

Hydroxyapatite is chosen for its similarity to natural bone mineral.

It is vital that the sintering process strengthens the material without altering its chemical identity. Precision temperature control ensures the material maintains its specific crystal structure throughout the heating cycle.

Understanding the Trade-offs

Strength vs. Phase Stability

There is a critical limit to how much heat HAp can endure.

If the temperature is too high or uncontrolled, HAp can undergo phase transformation, chemically changing into different calcium phosphates (like tricalcium phosphate). While the scaffold might be strong, this transformation can strip the material of the specific biological activity required for successful bone regeneration.

Densification vs. Porosity

While densification is necessary for the strength of the material "struts," the scaffold itself must remain porous on a macro scale for cell growth.

Over-sintering can lead to excessive shrinkage. This closes off the interconnected pores that biological tissues need to penetrate the scaffold, rendering it biologically inert despite its high strength.

Making the Right Choice for Your Goal

The sintering process is a balancing act between mechanics and biology. Here is how to prioritize your furnace parameters:

- If your primary focus is Maximum Mechanical Strength: Prioritize temperatures exceeding 1250°C to maximize solid-phase diffusion and the development of thick sintering necks.

- If your primary focus is Bioactivity and Purity: Strictly adhere to a controlled heating rate (e.g., 5°C/min) to prevent phase transformation and preserve the original HAp crystal structure.

The furnace is not just an oven; it is a precision tool that dictates whether your scaffold becomes a functional bone substitute or a failed ceramic.

Summary Table:

| Process Mechanism | Function in HAp Scaffolds | Critical Outcome |

|---|---|---|

| Solid-Phase Diffusion | Initiates atomic bonding across particle boundaries | Fuses ceramic powder into a unified structure |

| Sintering Neck Formation | Thickens bonds between adjacent particles | Converts fragile compacts into load-bearing units |

| Controlled Densification | Reduces micro-porosity within material struts | Enhances mechanical strength and structural rigidity |

| Precision Ramp Rates | Prevents rapid thermal expansion/contraction | Eliminates cracks, warping, and thermal shock damage |

| Phase Stability Control | Maintains specific HAp crystal structure | Preserves biological activity for bone regeneration |

Elevate Your Bioceramic Research with KINTEK Precision

Don't let uncontrolled thermal processing compromise your scaffold's structural integrity or bioactivity. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, and Vacuum furnace systems specifically designed for the delicate requirements of hydroxyapatite sintering. Our systems provide the precise ramp rates and temperature uniformity necessary to achieve maximum densification without sacrificing purity.

Whether you need a standard setup or a fully customizable high-temperature furnace for unique research needs, our team is ready to support your lab's mission.

Ready to optimize your sintering results? Contact us today to find your solution!

Visual Guide

References

- Ali Arab, Chunwei Zhang. Influence of Cell Geometry on the Mechanical and Failure Characteristics of 3D Voronoi Hydroxyapatite Through the Stereolithography Technique. DOI: 10.3390/ceramics8010004

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the main benefits of using a muffle furnace? Achieve Precise, Contamination-Free Heating for Your Lab

- What is a digital muffle furnace? A Guide to Contamination-Free, Precise Heating

- How does a high-temperature box muffle furnace convert mussel shells to calcium oxide? Expert Calcination Guide

- What is the difference between a muffle furnace and an oven? A Guide to High-Temperature Processing Purity

- What precautions should be taken when opening a muffle furnace after use? Essential Safety Steps for Lab Protection

- What are the advantages of using a muffle furnace? Achieve Precise, Contamination-Free Heat Treatment

- What PPE is necessary for performing maintenance or repairs on a benchtop furnace? Essential Gear for Lab Safety

- What role does a muffle furnace play in RH-SNP preparation? Master the Dual-Stage Thermal Synthesis