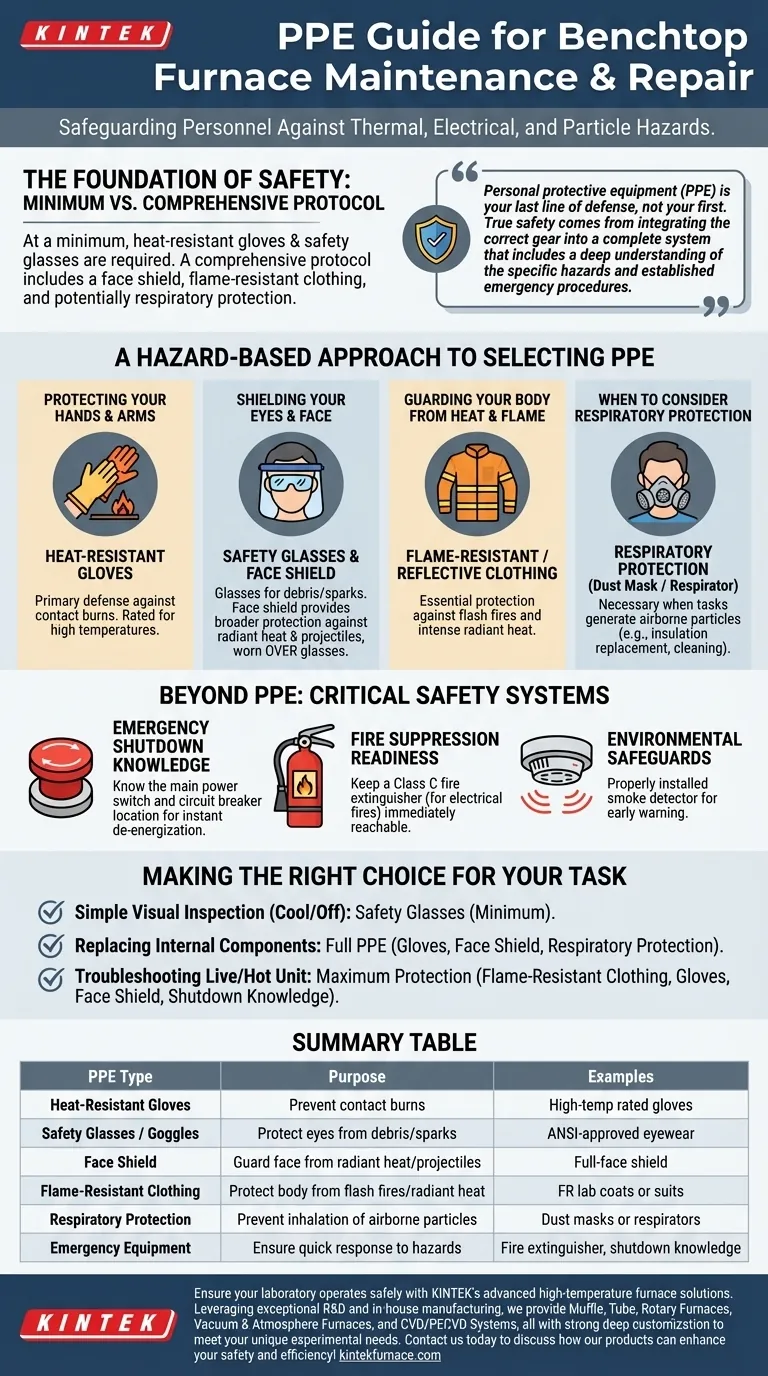

At a minimum, performing any maintenance or repair on a benchtop furnace requires heat-resistant gloves and safety glasses. However, a comprehensive safety protocol also mandates a face shield, flame-resistant clothing, and in some cases, respiratory protection to fully mitigate the risks of severe burns, electrical shock, and exposure to hazardous particles.

Personal protective equipment (PPE) is your last line of defense, not your first. True safety comes from integrating the correct gear into a complete system that includes a deep understanding of the specific hazards and established emergency procedures.

A Hazard-Based Approach to Selecting PPE

The specific PPE you need is directly tied to the hazard you are trying to prevent. A benchtop furnace presents multiple risks, including intense contact and radiant heat, electrical shock, airborne particles, and potential sparks or debris.

Protecting Your Hands and Arms

Heat-resistant gloves are non-negotiable. They are your primary defense against direct contact burns from hot surfaces, which can remain dangerously hot long after the furnace is powered down. Ensure your gloves are rated for the temperatures you will be working with.

Shielding Your Eyes and Face

Safety glasses or goggles must be worn at all times to protect your eyes from any unexpected debris or sparks. They are the baseline for eye protection.

For tasks that involve active heating elements or the potential for material spatter, a face shield worn over your safety glasses is critical. It provides a broader layer of protection for your entire face against both radiant heat and projectiles.

Guarding Your Body from Heat and Flame

Standard lab coats are often insufficient. Flame-resistant or heat-reflective clothing provides essential protection against flash fires and intense radiant heat that can cause severe burns even without direct contact.

When to Consider Respiratory Protection

Respiratory protection becomes necessary when your maintenance task could generate airborne particles. This is common when replacing old insulation, cleaning out debris, or working with materials that can produce dust or fumes. A simple dust mask or a more robust respirator should be chosen based on the specific material hazard.

Beyond PPE: Critical Safety Systems

Wearing the right gear is only one part of a safe work environment. Your procedures and surrounding equipment are equally, if not more, important.

Emergency Shutdown Knowledge

Before beginning any work, you must be able to perform an emergency shutdown of the furnace. This includes knowing the location of the main power switch and the circuit breaker, ensuring you can de-energize the unit instantly if a problem occurs.

Fire Suppression Readiness

Keep a fire extinguisher suitable for electrical fires (typically Class C) within immediate reach. A furnace combines high heat with high voltage, creating a significant fire risk that must be planned for.

Environmental Safeguards

A properly installed smoke detector in the work area provides a crucial early warning. Never assume you will be the first to notice a fire.

Making the Right Choice for Your Task

Use the nature of your task to determine the necessary level of protection.

- If your primary focus is a simple visual inspection (furnace cool and off): Safety glasses are the minimum requirement, though having your full kit accessible is best practice.

- If you are replacing internal components (e.g., heating elements, insulation): A full set of PPE is required, including heat-resistant gloves, face shield, and appropriate respiratory protection for dust.

- If you are troubleshooting a live or recently powered-down unit: Maximum protection is mandatory; this includes flame-resistant clothing, gloves, and a face shield, combined with absolute knowledge of the shutdown procedure.

A deliberate and well-prepared approach to safety transforms a hazardous task into a controlled, professional procedure.

Summary Table:

| PPE Type | Purpose | Examples |

|---|---|---|

| Heat-Resistant Gloves | Prevent contact burns from hot surfaces | High-temperature rated gloves |

| Safety Glasses / Goggles | Protect eyes from debris and sparks | ANSI-approved eyewear |

| Face Shield | Guard face against radiant heat and projectiles | Full-face shield worn over glasses |

| Flame-Resistant Clothing | Protect body from flash fires and radiant heat | FR lab coats or suits |

| Respiratory Protection | Prevent inhalation of airborne particles | Dust masks or respirators |

| Emergency Equipment | Ensure quick response to hazards | Fire extinguisher, emergency shutdown knowledge |

Ensure your laboratory operates safely with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our products can enhance your safety and efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care