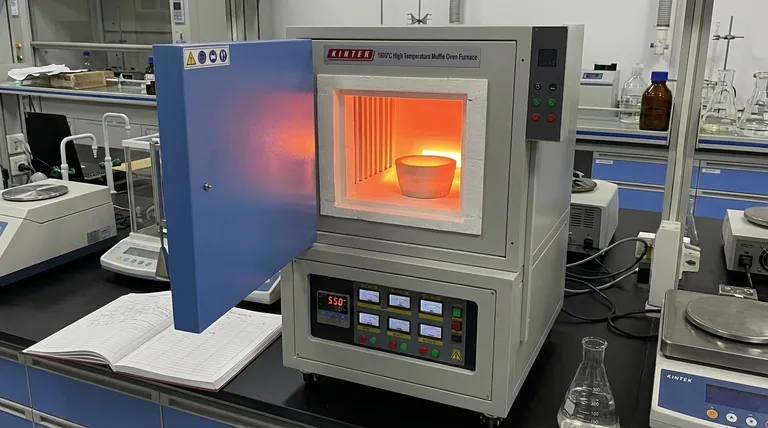

The high-temperature muffle furnace serves as the precise reaction chamber for creating the catalyst's final crystalline structure. It provides a stable 550°C thermal environment necessary to drive the polycondensation of melamine into graphitic carbon nitride (g-C3N4) while simultaneously transforming copper precursors into active monoclinic CuO. Without this specific thermal treatment, the material would remain a mixture of inactive precursors rather than a functional ternary heterostructure.

Core Takeaway The muffle furnace is not merely a drying tool; it is a structural architect. It orchestrates a controlled thermal ramp that ensures the chemical bonding, encapsulation, and orderly phase transformation required to stabilize the catalyst's active sites on the carrier.

Driving Essential Phase Transformations

Creating the Photoactive Skeleton

The primary function of the furnace during this stage is to facilitate thermal polycondensation.

At 550°C, the melamine precursor undergoes a complex chemical rearrangement. This reaction builds the graphitic carbon nitride (g-C3N4) framework, which is responsible for the catalyst's ability to respond to visible light.

Activating the Metal Components

Simultaneously, the furnace converts the copper components into their active form.

The heat drives the transformation of copper precursors into monoclinic CuO. This specific crystal phase is essential for the catalyst's chemical reactivity and works in tandem with the g-C3N4 layer.

Engineering the Heterostructure

Anchoring the Active Sites

The thermal treatment goes beyond simple conversion; it physically integrates the components.

The heat facilitates the secure anchoring of the CuO particles onto the SiO2 carrier. This creates a robust base that prevents the active metal sites from leaching or detaching during use.

The Encapsulation Process

The furnace environment ensures the orderly construction of a ternary heterostructure.

As the g-C3N4 forms, it encapsulates the CuO/SiO2 assembly. This wrapping effect protects the active centers and enhances the interaction between the different layers of the catalyst.

The Critical Role of Heating Rate

Preventing Structural Defects

The "ramp rate"—how fast the furnace heats up—is just as critical as the final temperature.

The primary reference specifies a precise heating rate of 5°C per minute. This controlled pace prevents thermal shock, allowing the complex heterostructure to assemble in an orderly, defect-free manner.

Ensuring Batch Consistency

A high-quality muffle furnace maintains a stable thermal field throughout the chamber.

This stability eliminates "cold spots" that could lead to incomplete reactions. It guarantees that every gram of the catalyst batch undergoes the exact same phase transformation, ensuring consistent performance.

Understanding the Trade-offs

Process Time vs. Crystal Quality

The requirement for a slow ramp rate (5°C/min) and sustained heating (often several hours) makes this a time-intensive process.

Rushing this stage by increasing the heating rate to save time is a common pitfall. It often leads to disordered structures or incomplete encapsulation, significantly degrading catalytic performance.

Energy Consumption

Maintaing 550°C for extended periods requires significant energy input.

While necessary for the SiO2@CuO/g-C3N4 synthesis, this energy cost must be factored into the scalability of catalyst production. The trade-off is a high-performance catalyst versus higher operational costs.

Making the Right Choice for Your Goal

When configuring your thermal treatment for SiO2@CuO/g-C3N4 synthesis, prioritize your parameters based on your desired outcome:

- If your primary focus is Structural Stability: strictly adhere to the 5°C/min ramp rate to ensure the CuO is securely anchored and fully encapsulated.

- If your primary focus is Photocatalytic Efficiency: verify that the furnace can hold a precise 550°C without fluctuation to maximize the crystallinity of the visible-light-responsive g-C3N4.

Precision in the thermal environment is the difference between a loose mixture of chemicals and a unified, high-performance catalyst.

Summary Table:

| Parameter | Specification | Role in Catalyst Synthesis |

|---|---|---|

| Target Temp | 550°C | Facilitates thermal polycondensation of melamine into g-C3N4 |

| Heating Rate | 5°C/min | Prevents structural defects and ensures orderly assembly |

| Atmosphere | Stable/Static Air | Drives the transformation of precursors into active monoclinic CuO |

| Process Goal | Heterostructure | Anchors active sites onto SiO2 carrier and ensures encapsulation |

Elevate Your Material Synthesis with KINTEK Precision

Don't let unstable thermal environments compromise your catalyst's performance. KINTEK provides industry-leading muffle and high-temperature furnace systems designed for the rigorous demands of material science.

Why choose KINTEK for your lab?

- Unmatched Thermal Stability: Eliminate cold spots to ensure 100% batch consistency.

- Precision Control: Master your 5°C/min ramp rates with advanced programmable controllers.

- Versatile Solutions: From Muffle and Tube furnaces to Vacuum and CVD systems, our equipment is fully customizable for your unique R&D needs.

Contact KINTEK today to consult with our expert R&D team and find the perfect high-temperature solution for your lab's success.

References

- Ternary SiO2@CuO/g-C3N4 Nanoparticles for Solar-Driven Photoelectrocatalytic CO2-to-Fuel Conversion. DOI: 10.3390/catal15090892

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What PPE is necessary for performing maintenance or repairs on a benchtop furnace? Essential Gear for Lab Safety

- What are the advantages of box furnaces in terms of versatility? Unlock Flexibility for Diverse Material Processing

- How should alkaline substances be handled in a muffle furnace? Protect Your Equipment from Corrosion

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are the key disadvantages of a muffle furnace? Slow cycles, high energy use, and maintenance challenges

- How does heat treatment in a muffle furnace enhance MnO2@g-C3N4 performance? Boost Catalytic Efficiency Today

- What features help box furnaces maintain uniform temperatures? Key Design Elements for Precise Heat Distribution

- How does a laboratory muffle furnace ensure product quality? Precision in Oxygen-Limited Biomass Pyrolysis