A laboratory muffle furnace ensures product quality by providing a strictly regulated thermal environment that isolates biomass from direct combustion. By utilizing precise heating programs—such as a constant ramp rate of 10 °C min⁻¹—and maintaining oxygen-limited conditions, the furnace steers the material through thermochemical decomposition rather than simple burning. This control is the deciding factor in defining the final structure and chemical consistency of the resulting biochar.

Core Takeaway The muffle furnace transforms biomass processing from a crude burn into precise material engineering. Its ability to decouple the heating source from the sample atmosphere allows you to dictate the exact porosity and surface chemistry of the final product by manipulating temperature ramps and residence times.

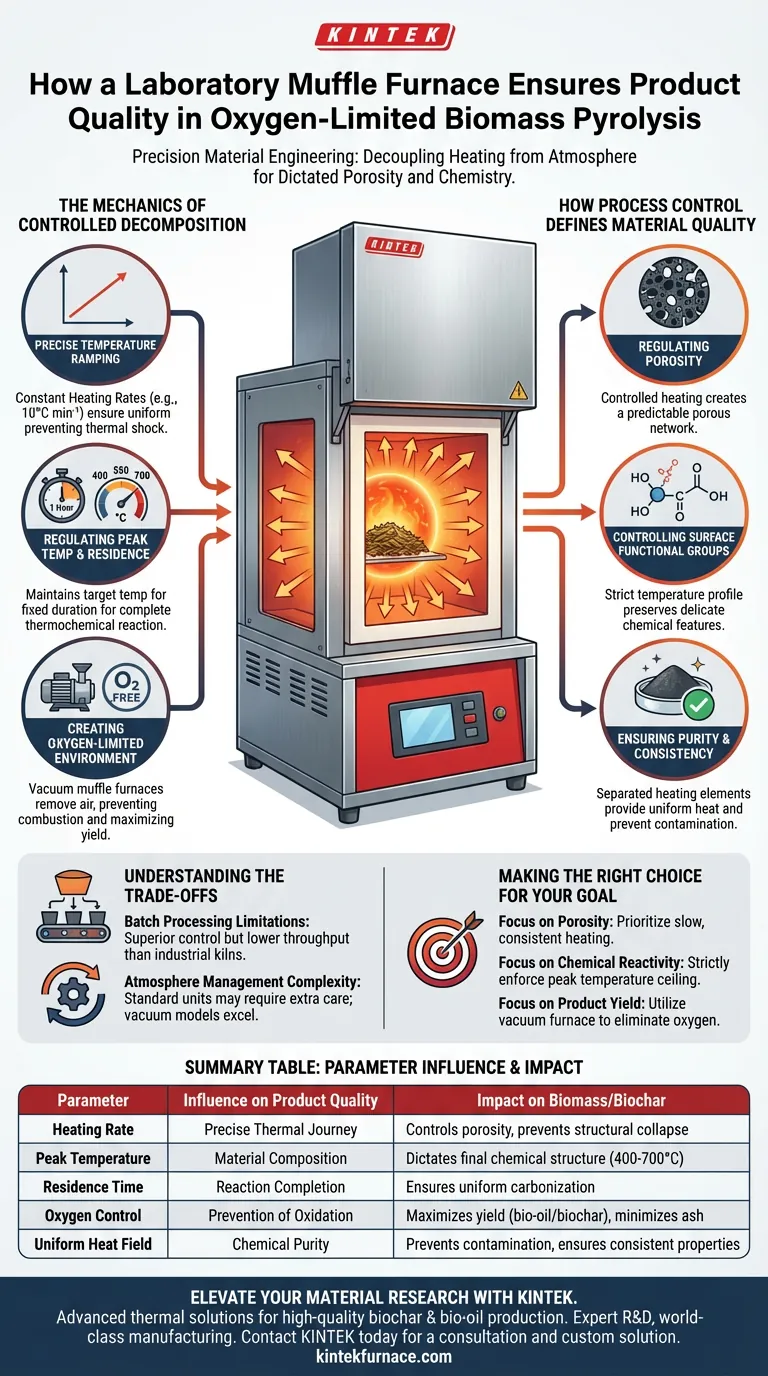

The Mechanics of Controlled Decomposition

Precise Temperature Ramping

Quality pyrolysis requires more than just reaching a high temperature; it requires a controlled journey to that temperature.

A muffle furnace utilizes digital control systems to execute constant heating rates (e.g., 10 °C min⁻¹). This gradual, linear increase ensures that the biomass decomposes uniformly, preventing thermal shock or uneven carbonization.

Regulating Peak Temperature and Residence

The furnace maintains the sample at specific target temperatures, such as 400, 550, or 700 °C, for a fixed duration, typically 1 hour.

This residence time is critical. It allows the thermochemical reactions to reach completion, ensuring the material is fully processed throughout its volume before cooling begins.

Creating an Oxygen-Limited Environment

To achieve pyrolysis rather than combustion, the presence of oxygen must be restricted.

Vacuum muffle furnaces are particularly effective here, creating essentially oxygen-free environments. By removing air from the chamber, the furnace ensures the biomass undergoes thermal degradation without oxidizing into ash, which is essential for maximizing the yield of bio-oils and biochar.

How Process Control Defines Material Quality

Regulating Porosity

The primary measure of biochar quality is often its physical structure.

The specific combination of heating rate and peak temperature directly regulates the resulting porosity of the material. Controlled heating drives off volatiles at a predictable rate, creating a porous network rather than collapsing the structure.

Controlling Surface Functional Groups

The chemical reactivity of the biochar is determined by the density of its surface functional groups.

By strictly adhering to the programmed temperature profile, the muffle furnace ensures these groups are preserved or transformed according to your specifications. Fluctuations in heat would otherwise destroy these delicate chemical features.

Ensuring Purity and Consistency

The design of a muffle furnace separates the heating elements from the main chamber (the "muffle").

Heat is radiated into the chamber, meaning the biomass never comes into contact with the heating coils or combustion gases. This provides a uniform temperature field and prevents contamination, ensuring the final product is chemically pure.

Understanding the Trade-offs

Batch Processing Limitations

Muffle furnaces are inherently batch-process devices.

While they offer superior control for laboratory-scale quality, they cannot match the continuous throughput of industrial rotary kilns. You gain precision and environmental control at the cost of processing speed and volume.

Atmosphere Management Complexity

Standard muffle furnaces are not always perfectly airtight compared to tube furnaces.

While a vacuum muffle furnace excels at oxygen elimination, a standard unit may require careful management or additional gas flow setups to maintain strict oxygen-limited conditions. Without a vacuum feature, creating a purely inert atmosphere can be more challenging.

Making the Right Choice for Your Goal

To maximize the quality of your biomass pyrolysis, tailor your furnace settings to your specific objective:

- If your primary focus is Physical Structure (Porosity): Prioritize a slow, consistent heating rate (e.g., 10 °C min⁻¹) to allow volatiles to escape without collapsing the pore structure.

- If your primary focus is Chemical Reactivity: Strictly enforce the peak temperature ceiling (e.g., stopping at 400 °C or 550 °C) to preserve the density of surface functional groups.

- If your primary focus is Product Yield (Bio-oils): Utilize a vacuum muffle furnace to eliminate oxygen entirely, preventing secondary oxidation of the valuable volatiles.

Precision in the thermal profile is the only way to turn raw biomass into a high-performance material.

Summary Table:

| Parameter | Influence on Product Quality | Impact on Biomass/Biochar |

|---|---|---|

| Heating Rate | Precise Thermal Journey | Controls porosity and prevents structural collapse |

| Peak Temperature | Material Composition | Dictates final chemical structure (e.g., 400°C to 700°C) |

| Residence Time | Reaction Completion | Ensures uniform carbonization through the sample volume |

| Oxygen Control | Prevention of Oxidation | Maximizes yield of bio-oil and biochar instead of ash |

| Uniform Heat Field | Chemical Purity | Prevents contamination and ensure consistent material properties |

Elevate Your Material Research with KINTEK

Precision in biomass pyrolysis is non-negotiable for high-quality biochar and bio-oil production. KINTEK provides the advanced thermal solutions necessary to transform raw materials into high-performance products.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you require precise atmosphere control or customizable temperature profiles for unique research needs, our lab high-temp furnaces are engineered for reliability and accuracy.

Ready to optimize your laboratory's heat treatment capabilities?

Contact KINTEK today for a consultation and custom solution.

Visual Guide

References

- Maryam Rabiee Abyaneh, Ali Daryabeigi Zand. Pb(ΙΙ), Cd(ΙΙ), and Mn(ΙΙ) adsorption onto pruning-derived biochar: physicochemical characterization, modeling and application in real landfill leachate. DOI: 10.1038/s41598-024-54028-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What maintenance checks are required for a muffle furnace? Ensure Safety and Accuracy in Your Lab

- What safety features do muffle furnaces have? Essential Protection for High-Temperature Operations

- What is the role of convective heat transfer in a box type resistance furnace? Unlock Efficient Heating Dynamics

- What function does a high-temperature muffle furnace serve in the preparation of Ni-doped LaFeO3 gas-sensing materials?

- What are the key considerations for temperature control when using a Muffle furnace? Master Precise Thermal Management

- How does a muffle furnace work in terms of heating principle? Discover Indirect Heating for Pure, Uniform Results

- What is the primary function of an electric muffle furnace? Ensure Purity and Uniform Heating

- How do high-precision heating furnaces ensure quality during high-temperature capillary imprinting? | KINTEK