Muffle furnaces are engineered with multiple layers of safety to protect operators from extreme temperatures and electrical hazards. Key safety features include robust physical insulation, emergency power-off systems like circuit breakers, and designs that isolate the heating elements from both the user and the material being processed.

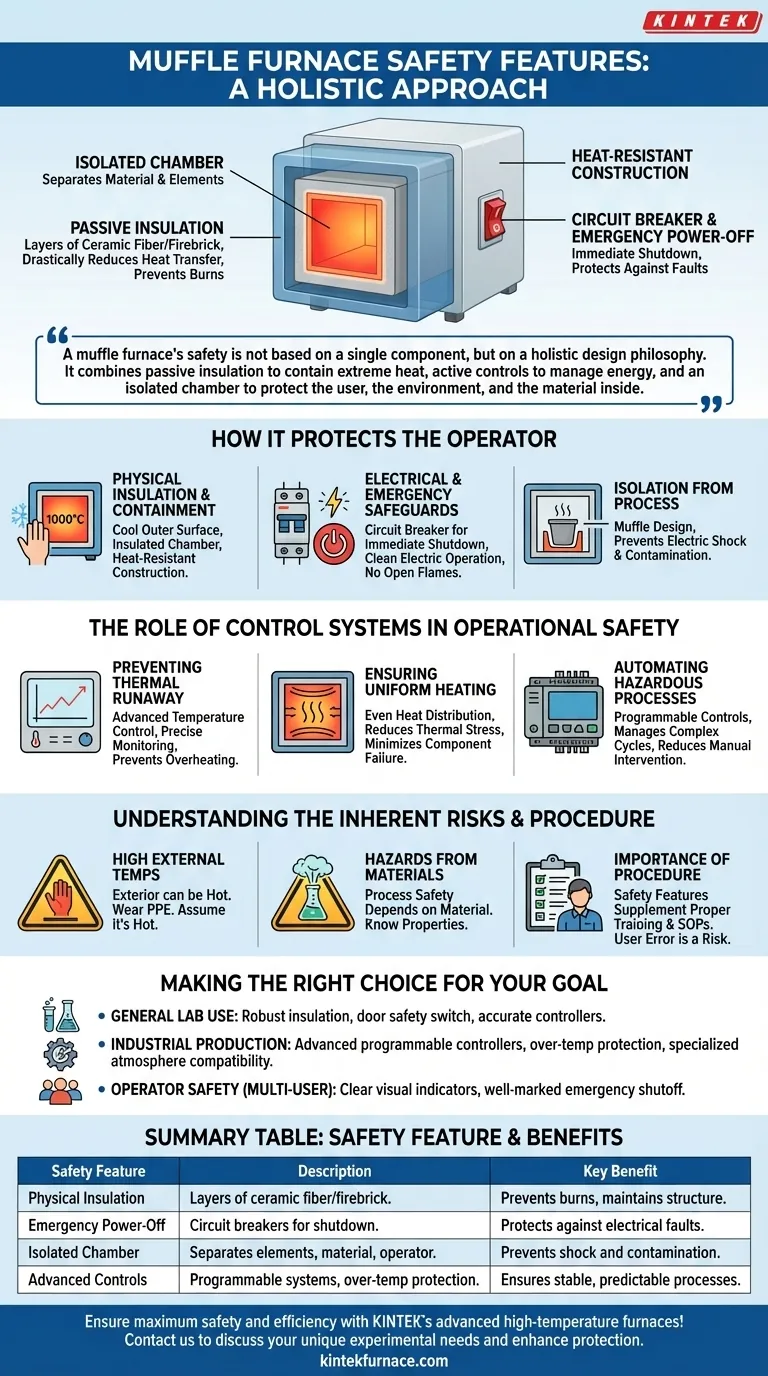

A muffle furnace's safety is not based on a single component, but on a holistic design philosophy. It combines passive insulation to contain extreme heat, active controls to manage energy, and an isolated chamber to protect the user, the environment, and the material inside.

How a Muffle Furnace Protects the Operator

The primary goal of a muffle furnace's design is to safely contain and control immense heat. This is achieved through a combination of physical barriers, electrical safeguards, and process isolation.

Physical Insulation and Heat Containment

A furnace's most visible safety feature is its ability to remain relatively cool on the outside while reaching temperatures over 1000°C on the inside.

The insulated chamber is the first line of defense. It uses layers of ceramic fiber or firebrick to drastically reduce heat transfer to the furnace's external casing, minimizing the risk of burns.

Heat-resistant construction ensures the furnace's structural integrity at high temperatures. The materials are chosen not just to withstand the heat but also to have low thermal conductivity where operator contact might occur.

Electrical and Emergency Safeguards

Beyond passive heat protection, active systems protect against electrical faults and thermal runaway.

A circuit breaker is a critical feature that allows for an immediate emergency power shutdown. This protects against electrical shorts and can be used to stop the heating process instantly if a problem arises.

The use of clean electric operation is an inherent safety advantage over fuel-fired furnaces. It eliminates the risks associated with open flames, combustible fuel storage, and harmful exhaust fumes.

Isolation from the Heating Process

The term "muffle" refers to the inner chamber that separates the material being heated from the actual heating elements.

This isolated chamber design prevents accidental electric shock from direct contact with the elements. It also protects the heating elements from contamination by the workpiece and ensures the workpiece is not contaminated by the elements, leading to a more controlled and predictable process.

The Role of Control Systems in Operational Safety

Modern muffle furnaces rely on sophisticated controls that do more than just set a temperature; they ensure the entire process remains stable and predictable, which is a cornerstone of safety.

Preventing Thermal Runaway

An advanced temperature control system is crucial for safety. By precisely monitoring and maintaining the set temperature, it prevents overheating conditions that could damage the furnace, destroy the sample, or create a fire hazard.

Ensuring Predictable, Uniform Heating

Even heat distribution throughout the chamber reduces thermal stress on both the furnace components and the workpiece. This uniformity minimizes the risk of component failure or unexpected reactions from the material being processed.

Automating Hazardous Processes

Many furnaces feature programmable controls that can automatically manage complex heating and cooling cycles. This automation reduces the need for manual operator intervention during the most hazardous high-temperature phases of a process.

Understanding the Inherent Risks

While well-designed, a muffle furnace is still a piece of high-temperature equipment that demands respect and proper procedure.

High External Temperatures

Despite excellent insulation, the external surfaces of a furnace—especially around the door and vents—can become hot enough to cause serious burns. Always assume the exterior is hot and wear appropriate personal protective equipment (PPE).

Hazards from Processed Materials

The furnace itself may be safe, but the process running inside it may not be. Heating certain materials can release toxic or flammable gases. The safety of the operation depends entirely on understanding the properties of the material being heated.

The Importance of Procedure

Safety features are a supplement to, not a replacement for, proper training and standard operating procedures (SOPs). User error remains a significant risk, and operators must be trained on the specific model and process they are using.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its features to your specific application and risk tolerance.

- If your primary focus is general lab use or heat treating: Prioritize models with robust insulation, a reliable door safety switch, and simple, accurate temperature controllers.

- If your primary focus is industrial production or volatile processes: Look for advanced features like programmable controllers with over-temperature protection alarms and compatibility with specialized atmospheres.

- If your primary focus is operator safety in a multi-user environment: Ensure the furnace has clear visual indicators for its operational state (heating/cooling/idle) and a well-marked emergency shutoff.

Ultimately, understanding how a muffle furnace's safety systems work together empowers you to operate it with the confidence and caution it requires.

Summary Table:

| Safety Feature | Description | Key Benefit |

|---|---|---|

| Physical Insulation | Layers of ceramic fiber or firebrick reduce heat transfer to the exterior. | Prevents burns and maintains structural integrity. |

| Emergency Power-Off | Circuit breakers allow immediate shutdown in case of electrical faults. | Protects against shorts and thermal runaway. |

| Isolated Chamber | Separates heating elements from the material and operator. | Prevents electric shock and contamination. |

| Advanced Controls | Programmable systems with over-temperature protection and uniform heating. | Ensures stable, predictable processes and reduces hazards. |

Ensure maximum safety and efficiency in your lab with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing protection and performance. Contact us today to discuss how our furnaces can benefit your specific applications and keep your operations secure!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization