At its core, a box furnace's versatility stems directly from its large, unobstructed internal chamber. This design allows it to accommodate a much wider range of material sizes, shapes, and quantities compared to more specialized furnaces, making it a general-purpose workhorse for both industrial production and diverse research applications.

The versatility of a furnace is defined by the problems it can solve. While other furnaces offer precision in specific areas like atmosphere control, the box furnace's primary advantage is its sheer capacity and flexibility, allowing it to handle a vast array of sample types and batch processes with repeatable, uniform heating.

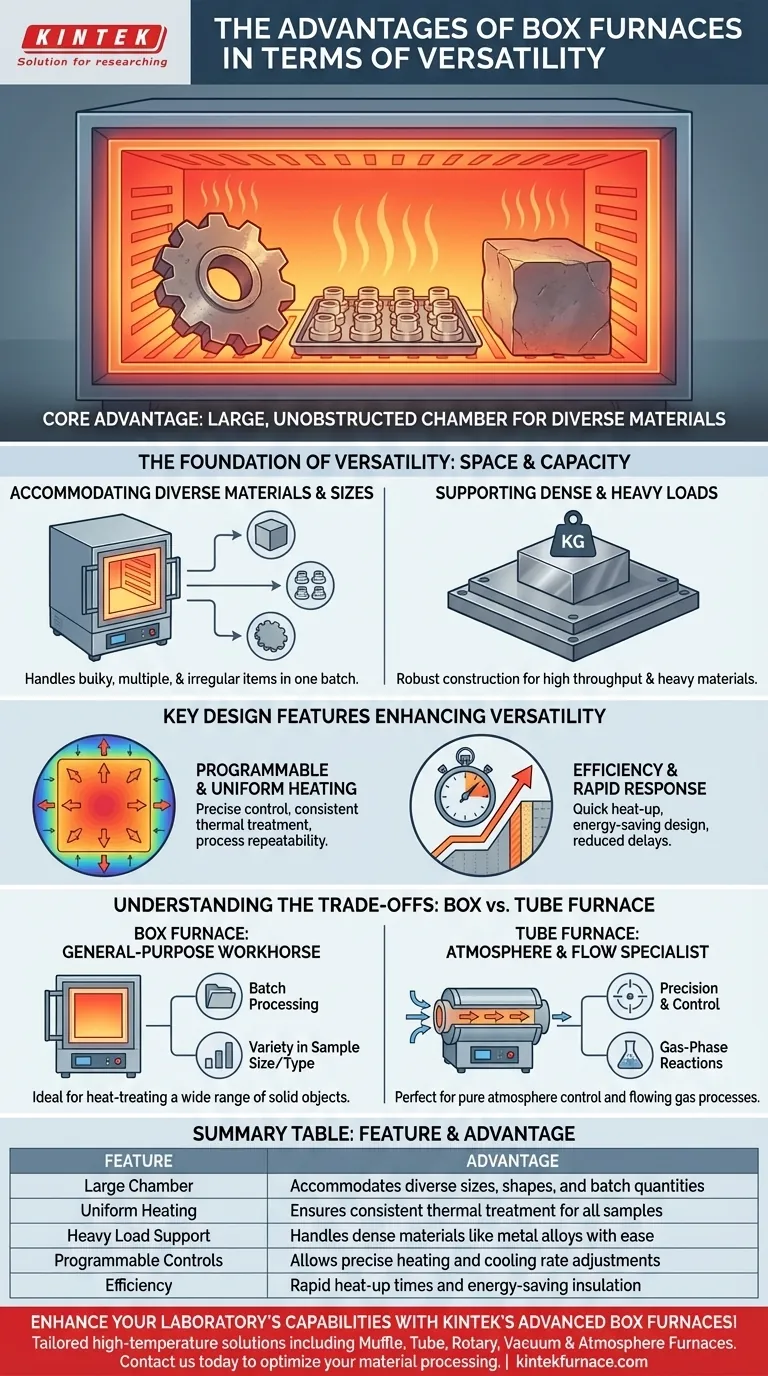

The Foundation of Versatility: Space and Capacity

The most significant advantage of a box furnace is its physical design. The large, rectangular chamber is inherently more adaptable than the confined space of a tube furnace.

Accommodating Diverse Materials and Sizes

A box furnace can easily handle bulky components, multiple small samples in a single batch, or materials with irregular shapes. This is a fundamental limitation in tube furnaces, which are restricted to samples that fit within the diameter of the tube.

This makes the box furnace ideal for processes like heat-treating large parts, sintering multiple components at once, or running quality tests on a variety of finished goods.

Supporting Dense and Heavy Loads

Box furnaces are engineered for durability. Their robust construction and sturdy hearth plates are designed to support dense and heavy loads without issue.

This capability is critical for industrial manufacturing where high throughput and the ability to process heavy materials like metal alloys are paramount.

Key Design Features That Enhance Versatility

Beyond simple capacity, specific engineering choices make box furnaces reliable tools for a wide range of applications.

Programmable and Uniform Heating

Modern box furnaces offer fully programmable control over heating and cooling rates. Combined with modular plate heating elements and advanced insulation, they provide highly uniform temperature distribution across the entire chamber.

This ensures that every sample in a batch, regardless of its position, receives the same consistent thermal treatment, which is crucial for process repeatability.

Efficiency and Rapid Response

Features like double-shell construction and energy-saving insulation not only reduce external surface temperatures for safety but also improve thermal efficiency.

This design allows for rapid heat-up times and quick thermal response, enabling users to run different processes with different temperature profiles without long delays between cycles.

Understanding the Trade-offs: Box vs. Tube Furnace

To truly understand a box furnace's versatility, it's essential to compare it to its most common alternative, the tube furnace. Each is versatile in a different way.

Box Furnace: The General-Purpose Workhorse

The box furnace excels at batch processing and handling variety in sample size and type. Its strength lies in its simplicity and large capacity. If your primary need is to heat-treat a wide range of solid objects in air or an inert atmosphere, the box furnace is often the superior choice.

Tube Furnace: The Atmosphere and Flow Specialist

A tube furnace's versatility comes from its precision and control. The tubular design makes it exceptionally good at maintaining a pure, controlled atmosphere (like hydrogen or argon) and is ideal for processes involving chemical vapors or flowing gas. They can also feature multiple heating zones for creating precise temperature gradients along the tube.

Choosing the Right Furnace for Your Application

Your choice depends entirely on the specific demands of your process.

- If your primary focus is processing a wide variety of sample sizes, shapes, or large batches: A box furnace offers the unmatched capacity and physical flexibility you need.

- If your primary focus is precise atmosphere control, gas-phase reactions, or continuous flow processing: A tube furnace is purpose-built for these specialized tasks.

- If your primary focus is general-purpose research or quality testing on diverse materials: A box furnace provides the adaptability to handle many different experiments and sample types.

Ultimately, selecting the right furnace is about matching the tool's inherent strengths to your specific operational goals.

Summary Table:

| Feature | Advantage |

|---|---|

| Large Chamber | Accommodates diverse sizes, shapes, and batch quantities |

| Uniform Heating | Ensures consistent thermal treatment for all samples |

| Heavy Load Support | Handles dense materials like metal alloys with ease |

| Programmable Controls | Allows precise heating and cooling rate adjustments |

| Efficiency | Rapid heat-up times and energy-saving insulation |

Enhance your laboratory's capabilities with KINTEK's advanced box furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to precisely meet your unique experimental needs. Contact us today to discuss how our versatile box furnaces can optimize your material processing and boost efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation