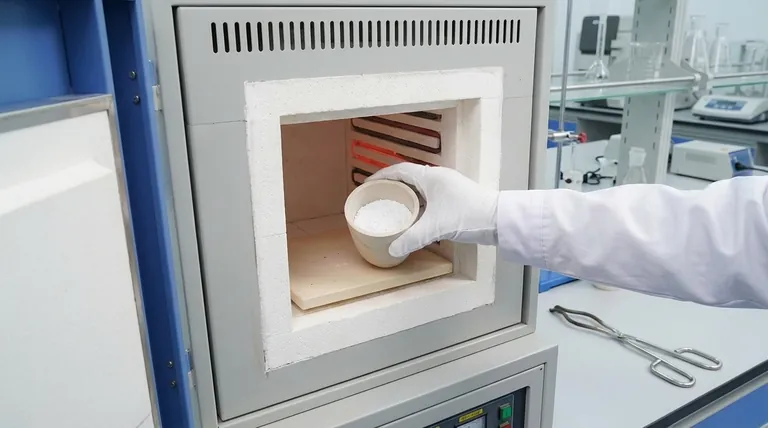

To handle alkaline substances in a muffle furnace, you must place them on a refractory plate inside the furnace chamber. This plate acts as a protective barrier, preventing the highly corrosive materials from reacting with and damaging the furnace’s internal lining at high temperatures. This simple step is the most critical measure for preserving the integrity of your equipment.

The core challenge with alkaline substances is not the heat itself, but the chemical attack they launch on furnace materials at high temperatures. Your primary goal is to create a physical barrier between the corrosive sample and the expensive furnace interior.

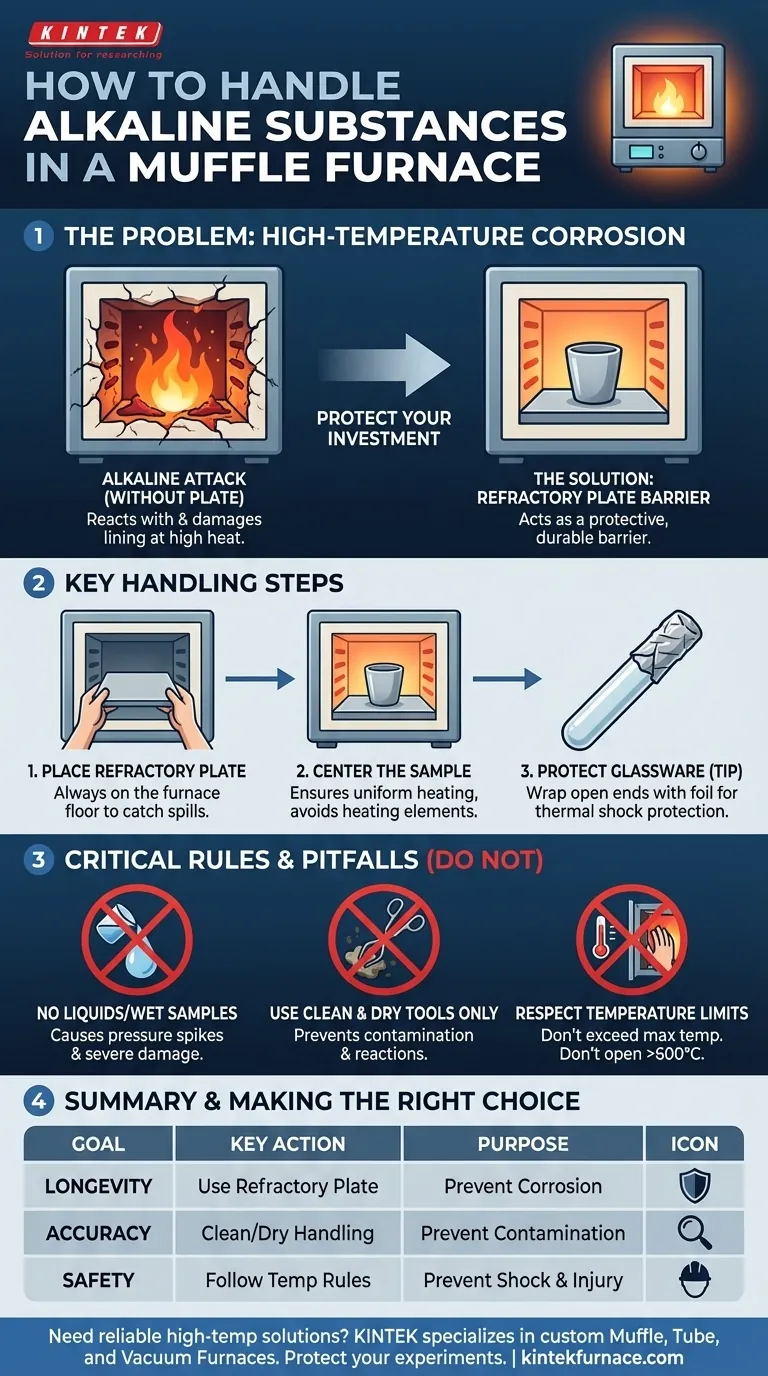

The Core Problem: High-Temperature Corrosion

Why Alkaline Substances Are a Threat

At room temperature, alkaline materials may seem stable. However, when heated in a muffle furnace, they become highly reactive.

These molten or heated substances can chemically attack, etch, and corrode the materials that make up the furnace's inner chamber, leading to permanent damage and costly repairs.

The Vulnerability of Furnace Linings

Muffle furnace chambers are typically constructed from specialized materials like quartz or ceramics, chosen for their thermal resistance and insulation.

While robust against heat, these refractory materials are susceptible to chemical attack from strong bases. Direct contact with heated alkaline substances will degrade this lining over time.

Protecting Your Muffle Furnace

The Primary Solution: Refractory Plates

The most effective way to prevent corrosion is to use a refractory plate (also known as a hearth plate or tray).

Place this plate on the furnace floor and set your crucible or sample directly on top of it. The plate acts as a sacrificial, durable barrier that absorbs any potential spills or reactions, protecting the furnace chamber itself.

Ensure Proper Sample Placement

Always place the refractory plate and your sample in the center of the furnace.

This positioning ensures the most uniform heat distribution for your experiment and keeps the sample away from direct contact with the heating elements on the furnace walls.

A Note on Protecting Glassware

When heating materials in certain types of glass, like Pyrex, you can take an extra step to prevent contamination or thermal shock.

Wrapping the open ends or smaller glass items in aluminum foil can help protect the sample and the glassware itself during the heating process.

Common Pitfalls and Critical Rules to Follow

Never Introduce Liquids

It is strictly forbidden to pour any liquids or molten metals directly into the furnace chamber.

Likewise, do not place samples that are wet or have oil on them inside. The rapid vaporization can create a pressure spike, spatter material, and cause severe damage to the heating elements and refractory lining.

Maintain Dry and Clean Handling

Use only clean, dry tongs and tools to handle samples. Introducing water or oil from contaminated tools poses the same risk as placing a wet sample into the furnace.

This discipline prevents both equipment damage and contamination of your experiment.

Respect Temperature and Physical Limits

Never operate the furnace above its maximum rated temperature. Avoid opening the furnace door when the internal temperature is above 600°C to prevent thermal shock to the chamber and ensure operator safety.

When the experiment is complete, allow the furnace to cool down gradually before removing your samples. Sudden temperature changes can crack the refractory materials.

Making the Right Choice for Your Goal

Following best practices is not just about one rule, but about a holistic approach to your specific objective.

- If your primary focus is equipment longevity: Always use a refractory plate as a non-negotiable barrier when heating any alkaline or potentially corrosive substance.

- If your primary focus is experimental accuracy: Ensure your samples, crucibles, and handling tools are completely clean and dry to prevent unwanted reactions or contamination.

- If your primary focus is operator safety: Adhere strictly to temperature limits, never open a hot furnace, and ensure your workspace is clear of all flammable materials.

By treating the furnace with this level of care, you ensure reliable experimental results and protect your valuable equipment for years to come.

Summary Table:

| Handling Step | Key Action | Purpose |

|---|---|---|

| Use Refractory Plate | Place sample on plate inside furnace | Acts as barrier to prevent corrosion of furnace lining |

| Sample Placement | Center sample in furnace | Ensures uniform heating and avoids contact with elements |

| Avoid Liquids | Never introduce wet or liquid samples | Prevents pressure spikes, spatter, and damage |

| Temperature Control | Do not exceed max temperature or open door above 600°C | Prevents thermal shock and ensures safety |

Need reliable high-temperature solutions for your lab? KINTEK specializes in advanced furnace systems like Muffle, Tube, and Vacuum Furnaces, with deep customization to meet your unique needs. Protect your experiments and equipment—contact us today for expert advice and tailored solutions!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production