In practice, the key disadvantages of a muffle furnace stem directly from its core design: an insulated, sealed chamber. These limitations primarily involve slow operational speed, high energy consumption, challenging maintenance, and an inability to handle applications requiring a vacuum.

The insulated, refractory chamber that gives a muffle furnace its signature temperature stability is also the source of its main drawbacks. This design creates a fundamental trade-off between thermal uniformity and operational efficiency, speed, and maintenance access.

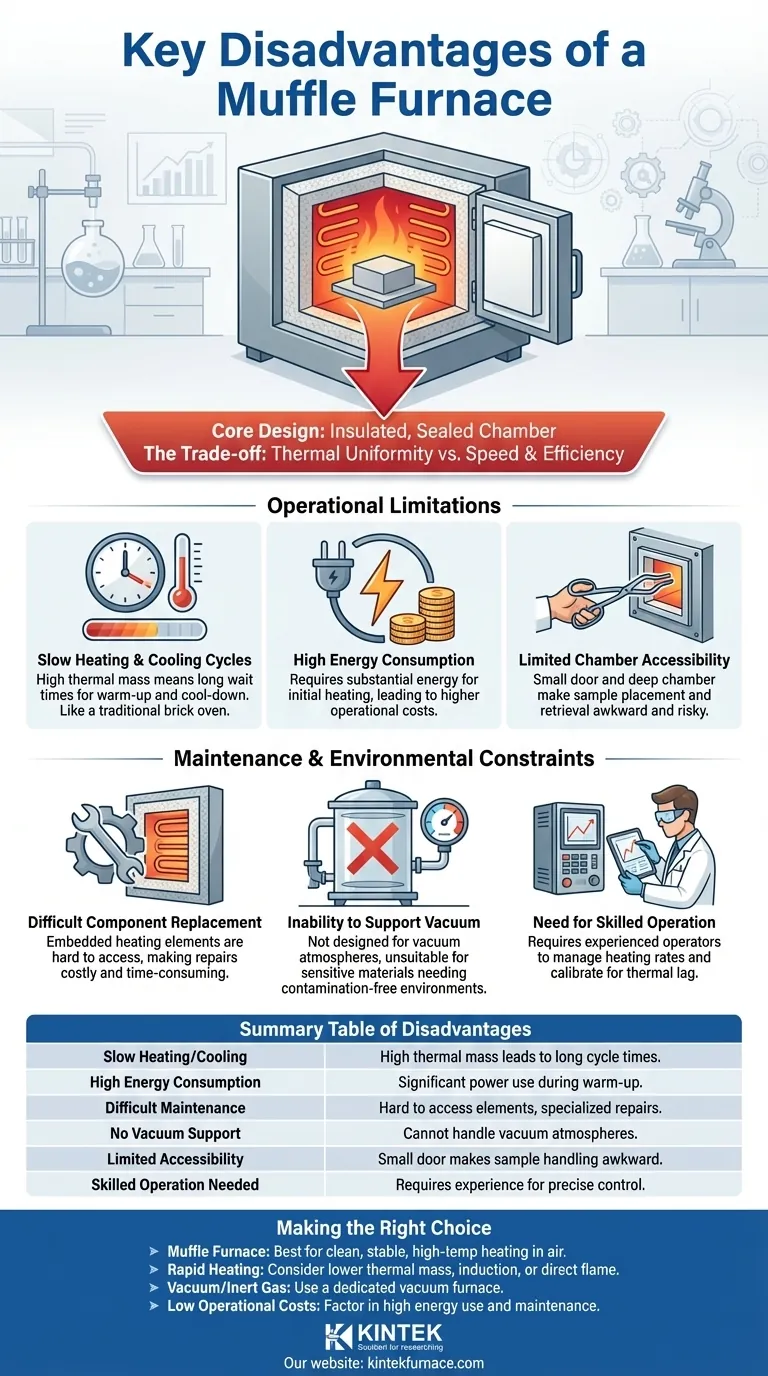

Understanding the Operational Limitations

A muffle furnace's design is optimized for stable, high-temperature work in ambient air, but this creates several practical challenges during day-to-day use.

Slow Heating and Cooling Cycles

A muffle furnace contains a significant amount of dense, insulating material (the "muffle"). This material has high thermal mass, meaning it heats up and cools down very slowly.

Think of it like a traditional brick pizza oven. It takes a long time to get to temperature, but once hot, it stays hot. This results in longer wait times for both the beginning and end of a process.

High Energy Consumption

Bringing the heavy insulation and chamber up to the target temperature requires a substantial amount of energy. The furnace consumes significant power, especially during the initial warm-up phase.

This can lead to higher operational costs compared to methods with lower thermal mass, particularly for labs or facilities with frequent, short-duration heating cycles.

Limited Chamber Accessibility

The design necessitates a relatively small door opening into a deep chamber. This can make placing and retrieving samples awkward, requiring long tongs and careful maneuvering.

Arranging multiple samples for uniform heat exposure can be challenging and increases the risk of accidental contact with the hot chamber walls.

Maintenance and Environmental Constraints

Beyond daily operations, the long-term ownership and specific application environment of a muffle furnace present further disadvantages.

Difficult Component Replacement

The heating elements are often embedded within or situated behind the furnace's refractory walls to protect them and ensure even heating.

While this protects the elements, it makes them extremely difficult to access for inspection or replacement. This process can be costly and time-consuming, often requiring a specialized technician.

Inability to Support Vacuum Atmospheres

A standard muffle furnace is not designed to hold a vacuum. Its construction is meant for operation in air and cannot withstand the pressure differences required for vacuum work.

For processes like sintering sensitive materials or heat-treating reactive metals that require a contamination-free environment, a vacuum furnace is the necessary and correct tool.

Need for Skilled Operation

While seemingly simple, achieving precise and repeatable results requires experience. The operator must understand how to manage heating rates and soak times to compensate for the furnace's thermal lag.

Adjusting and calibrating the temperature controller requires specific knowledge to ensure the accuracy of the thermal process.

Understanding the Trade-offs

The disadvantages of a muffle furnace are best understood as trade-offs for its primary benefit: providing a stable, uniform, and isolated heating environment free from the byproducts of combustion.

The Core Trade-off: Isolation vs. Speed

The "muffle" creates a barrier between the heating elements and the workload. This ensures clean, uniform radiant heat but also acts as an insulator, slowing down heat transfer and making the system less responsive.

Muffle Furnace vs. Open-Flame Methods

Direct flame heating is much faster and more energy-efficient for simply getting an object hot. However, it offers poor temperature control and exposes the material to combustion gases, which is unacceptable for most lab-grade applications.

Muffle Furnace vs. Vacuum Furnace

A muffle furnace is ideal for heating in air. A vacuum furnace is required for heating in a controlled vacuum or inert gas environment. They serve fundamentally different purposes and are not interchangeable.

Making the Right Choice for Your Application

Selecting the right furnace requires matching its characteristics to your primary process goal.

- If your primary focus is clean, stable, high-temperature heating in air: A muffle furnace is an excellent choice, provided you can accommodate its slower cycle times and higher energy use.

- If your primary focus is rapid heating and cooling: A muffle furnace is a poor fit; consider furnaces with lower thermal mass or alternative heating methods like induction or direct flame.

- If your primary focus is processing in a vacuum or inert gas: A muffle furnace is unsuitable. You must use a vacuum furnace designed for these atmospheric conditions.

- If your primary focus is minimizing long-term operational costs: Carefully factor in the high energy consumption and potential for costly maintenance when evaluating if a muffle furnace fits your budget.

Ultimately, understanding these inherent limitations ensures you select a tool that accelerates, rather than hinders, your work.

Summary Table:

| Disadvantage | Description |

|---|---|

| Slow Heating/Cooling | High thermal mass leads to long cycle times, delaying processes. |

| High Energy Consumption | Significant power use during warm-up increases operational costs. |

| Difficult Maintenance | Heating elements are hard to access, requiring specialized repairs. |

| No Vacuum Support | Cannot handle vacuum atmospheres, limiting application scope. |

| Limited Accessibility | Small door and deep chamber make sample handling awkward. |

| Skilled Operation Needed | Requires experience for precise temperature control and calibration. |

Struggling with slow furnace cycles or high energy costs? KINTEK offers advanced high-temperature solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental requirements. Enhance your lab's efficiency and reduce operational expenses—contact us today for a consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation