A high-temperature muffle furnace is indispensable for this analysis because it provides the sustained, extreme heat necessary to completely incinerate the organic matrix of the sample. Specifically, by maintaining a temperature of 550°C for extended periods, the furnace ensures the total oxidation of organic matter, isolating the inorganic mineral content for accurate measurement.

The muffle furnace facilitates the precise quantification of mineral content by eliminating all organic components, creating a reliable baseline to assess how different processing methods affect the nutritional value of the banana powder.

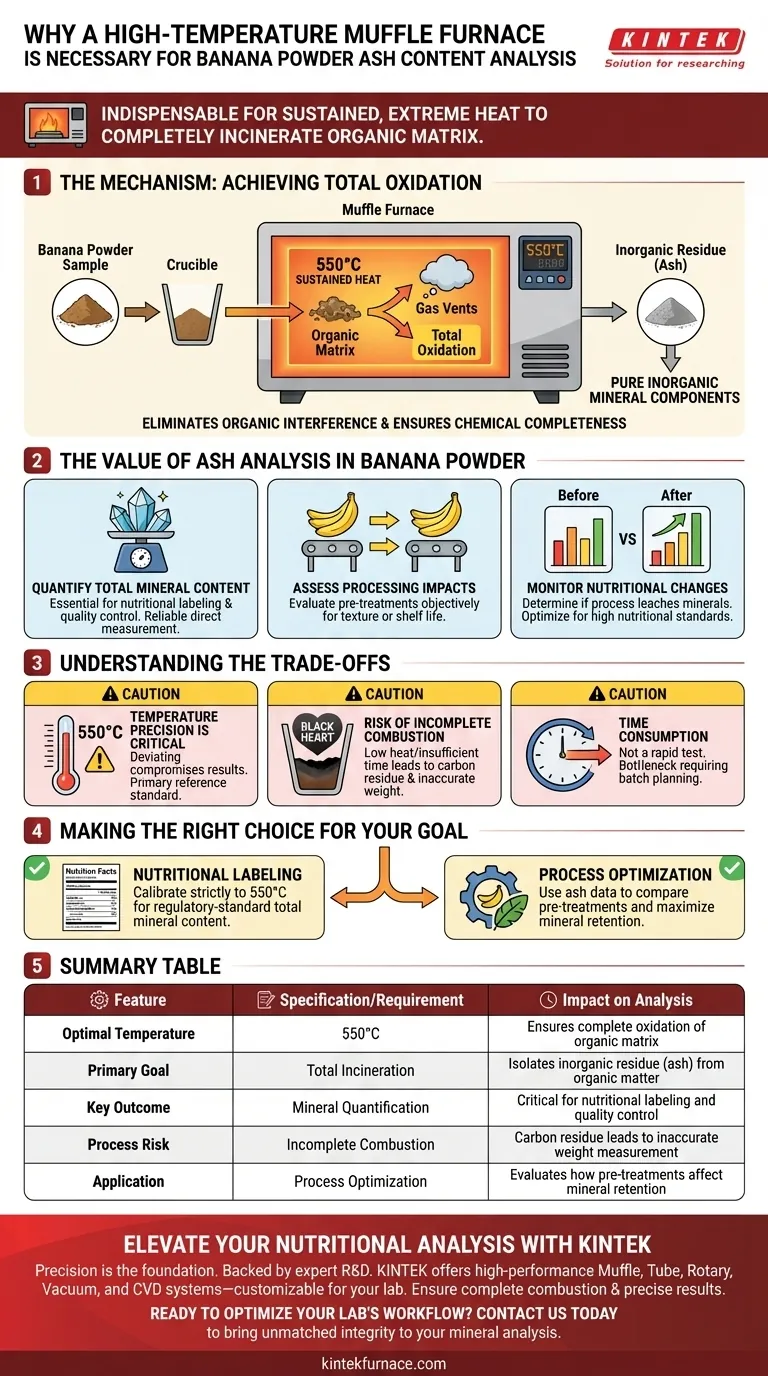

The Mechanism: Achieving Total Oxidation

Eliminating Organic Interference

The primary function of the muffle furnace is to create a controlled environment where organic matter cannot survive. At temperatures like 550°C, the carbon-based organic structures within the banana powder are chemically broken down and converted into gases.

Isolating Inorganic Residue

Once the organic material oxidizes and vents away, only the non-combustible material remains. This residue is the "ash," which represents the pure inorganic mineral components of the banana powder.

Ensuring Chemical Completeness

This process is not merely about heating; it is about driving a chemical reaction to completion. The furnace ensures that no organic carbon remains, which would otherwise falsely inflate the weight of the ash and skew analytical results.

The Value of Ash Analysis in Banana Powder

Quantifying Total Mineral Content

For researchers and producers, knowing the exact mineral payload is essential for nutritional labeling and quality control. The muffle furnace provides the only reliable method to strip away the "noise" of the organic material to measure these minerals directly.

Assessing Processing Impacts

Banana powder often undergoes various pre-treatments during manufacturing to improve texture or shelf life. Ash content analysis allows you to evaluate these treatments objectively.

Monitoring Nutritional Changes

By comparing the ash content before and after specific treatments, you can determine if a process is leaching minerals or altering the nutritional profile. This data is critical for optimizing production to maintain high nutritional standards.

Understanding the Trade-offs

Temperature Precision is Critical

While high heat is necessary, precision is equally important. The primary reference specifies 550°C for banana powder; deviating significantly from this standard can compromise results.

Risk of Incomplete Combustion

If the temperature drops too low or the time in the furnace is insufficient, organic matter will remain in the sample. This leads to "black heart" or carbon residue, rendering the weight measurement inaccurate.

Time Consumption

This is not a rapid test method. The requirement for "extended periods" of incineration means this process is a bottleneck in workflow, requiring batch planning rather than instant analysis.

Making the Right Choice for Your Goal

To effectively utilize a muffle furnace for banana powder analysis, align your procedure with your specific analytical objectives:

- If your primary focus is nutritional labeling: Ensure your furnace is calibrated strictly to 550°C to obtain a regulatory-standard measurement of total mineral content.

- If your primary focus is process optimization: Use ash content data to compare different pre-treatment batches, selecting the method that maximizes mineral retention.

Correctly utilizing a muffle furnace transforms raw data into a clear window into the purity and nutritional integrity of your final product.

Summary Table:

| Feature | Specification/Requirement | Impact on Analysis |

|---|---|---|

| Optimal Temperature | 550°C | Ensures complete oxidation of organic matrix |

| Primary Goal | Total Incineration | Isolates inorganic residue (ash) from organic matter |

| Key Outcome | Mineral Quantification | Critical for nutritional labeling and quality control |

| Process Risk | Incomplete Combustion | Carbon residue leads to inaccurate weight measurement |

| Application | Process Optimization | Evaluates how pre-treatments affect mineral retention |

Elevate Your Nutritional Analysis with KINTEK

Precision is the foundation of reliable ash content evaluation. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique laboratory requirements. Whether you are performing routine quality control or complex food science research, our high-temperature furnaces provide the thermal stability and accuracy you need to ensure complete combustion and precise results.

Ready to optimize your lab's workflow? Contact us today to discover how KINTEK’s advanced heating solutions can bring unmatched integrity to your mineral analysis.

Visual Guide

References

- IMPACT OF DIFFERENT PRETREATMENTS ON NUTRITIONAL, FUNCTIONAL, AND COLOR PROPERTIES OF BANANA FLOUR. DOI: 10.51470/plantarchives.2025.v25.no.1.278

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the standard features of box furnaces? Unlock Precision and Efficiency in Thermal Processing

- What precautions should be taken for the first use or after long-term shutdown of a muffle furnace? Ensure Safe, Reliable Operation from Day One

- What is the role of convective heat transfer in a box type resistance furnace? Unlock Efficient Heating Dynamics

- What is the role of a laboratory box high-temperature furnace in the post-processing of talc nanosheet powders?

- What role does a high-performance muffle furnace play in the synthesis of Co3O4 nanoparticles from precursor gels?

- How is a muffle furnace utilized during the high-temperature annealing of forged TiAl-SiC composites?

- What are the key disadvantages of a muffle furnace? Slow cycles, high energy use, and maintenance challenges

- Why are muffle furnaces important in quality control? Ensure Product Integrity with Controlled Heat Testing