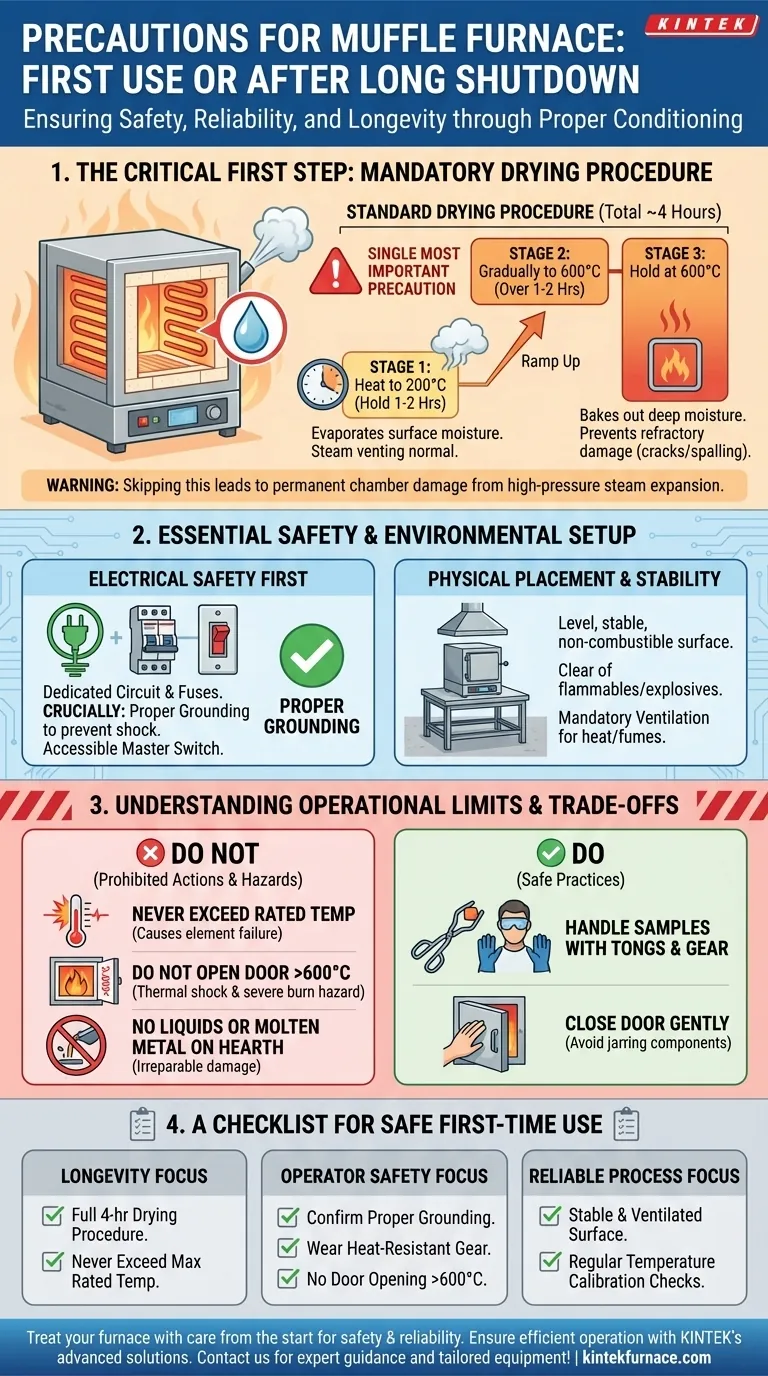

The single most important precaution for using a muffle furnace for the first time, or after a long shutdown, is to perform a mandatory drying procedure. This involves slowly heating the furnace over several hours to safely evaporate any moisture absorbed by its internal refractory materials. Skipping this step can lead to significant and permanent damage to the furnace chamber.

Your core challenge is not just turning the furnace on, but conditioning it for safe, reliable operation. The goal is to prevent damage from trapped moisture and establish a secure working environment from the very first use.

The Critical First Step: Drying the Furnace Chamber

When a muffle furnace sits unused, its porous ceramic refractory materials naturally absorb moisture from the air. This initial drying cycle is essential to prevent that moisture from causing damage.

Why Drying is Non-Negotiable

Rapidly heating a moisture-laden furnace turns the trapped water into high-pressure steam. This expansion can cause the refractory bricks or fiber insulation to crack, spall, or even shatter, compromising the furnace's integrity and lifespan.

The Standard Drying Procedure

While specific manufacturer guidelines should always be followed, a general procedure involves a slow, staged heating process.

First, heat the furnace to 200°C and hold it at that temperature for one to two hours. You may see steam venting from the door or exhaust port; this is normal.

Next, gradually increase the temperature to 600°C over the next one to two hours. Holding at this higher temperature ensures all deeper moisture is baked out. The entire process should take approximately four hours.

Essential Safety and Environmental Setup

Before you even begin the drying process, the furnace's environment and electrical connections must be secure.

Electrical Safety First

The furnace must be placed on a dedicated electrical circuit with the appropriate plugs, sockets, and fuses to handle its power draw.

Crucially, ensure the unit is properly grounded to prevent the risk of electric shock. An accessible master power switch or gate should be used to control the main supply.

Physical Placement and Stability

Position the furnace on a level, stable, and non-combustible surface, such as a concrete platform or a heavy-duty steel lab bench.

Ensure the surrounding area is clear of any flammable, explosive, or corrosive substances. Proper ventilation is also mandatory to safely dissipate heat and any potential fumes from the materials being processed.

Understanding Operational Limits and Trade-offs

A muffle furnace is a powerful tool, but it operates under strict limitations that must be respected to avoid failure and ensure safety.

Never Exceed the Rated Temperature

Operating the furnace above its maximum rated temperature will cause rapid degradation and failure of the heating elements. Even running it at the maximum rated temperature for excessively long periods can significantly shorten its operational life.

The Danger of High-Temperature Door Opening

Do not open the furnace door at temperatures above 600°C. The sudden change in temperature creates thermal shock, which can crack the hot refractory materials inside the chamber and the door insulation. It also presents a severe burn hazard from the intense radiant heat.

Prohibited Materials and Actions

Never pour liquids or attempt to bake items that could release significant liquid into the furnace chamber. Additionally, do not pour molten metal directly onto the furnace hearth, as this will cause irreparable damage.

Always handle samples with appropriate tongs and protective gear. Close the furnace door gently to avoid jarring the internal components.

A Checklist for Safe First-Time Use

Use this checklist to ensure you address the key priorities for your specific situation.

- If your primary focus is equipment longevity: Execute the full four-hour drying procedure without fail and never exceed the furnace's maximum rated temperature.

- If your primary focus is operator safety: Confirm proper electrical grounding, wear heat-resistant gloves and safety goggles, and never open the door above 600°C.

- If your primary focus is establishing a reliable process: Ensure the furnace is on a stable, level surface in a well-ventilated area, and perform regular checks on its temperature calibration for accuracy.

By treating the furnace with methodical care from the very beginning, you ensure its safety, reliability, and longevity.

Summary Table:

| Precaution Type | Key Steps | Purpose |

|---|---|---|

| Drying Procedure | Heat to 200°C for 1-2 hours, then to 600°C over 1-2 hours | Evaporate moisture to prevent refractory damage |

| Safety Setup | Ensure proper grounding, stable placement, and ventilation | Prevent electric shock, fires, and ensure operator safety |

| Operational Limits | Do not exceed rated temperature, avoid door opening above 600°C | Extend furnace life and avoid thermal shock |

Ensure your lab's muffle furnace operates safely and efficiently with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today for expert guidance and reliable equipment tailored to your experiments!

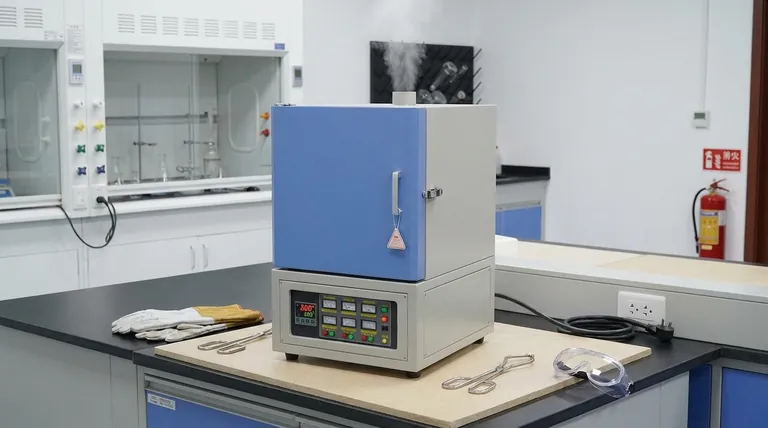

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?