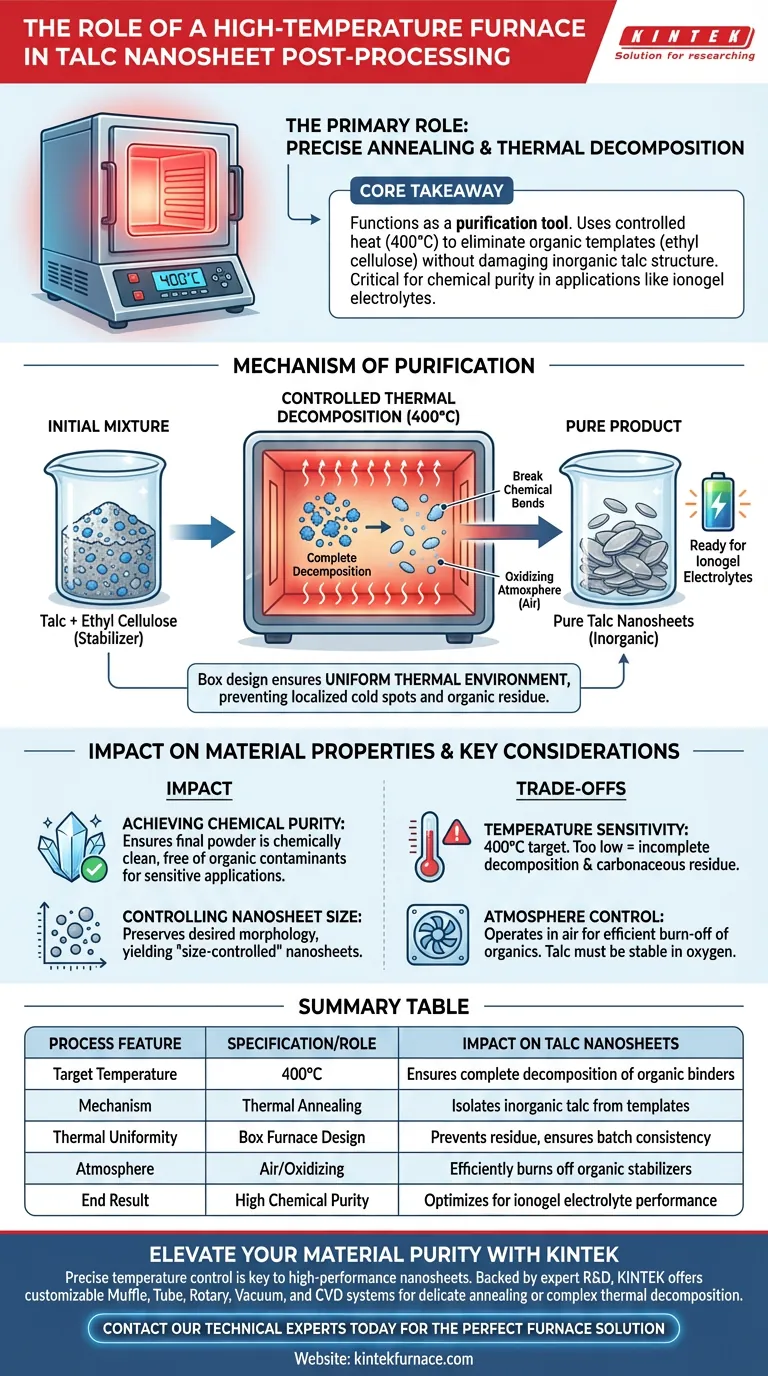

The primary role of a laboratory box high-temperature furnace in this context is to facilitate the precise annealing of talc and ethyl cellulose mixed powders. By maintaining a specific temperature of 400°C, the furnace drives the thermal decomposition of ethyl cellulose, which serves as a temporary stabilizer or template during the initial formation of the nanosheets. This thermal treatment is the decisive step that isolates the inorganic talc from the organic binders.

Core Takeaway: The furnace functions as a purification tool, utilizing controlled heat to eliminate organic templates without damaging the inorganic structure. This step is critical for achieving the chemical purity required for high-performance applications like ionogel electrolytes.

The Mechanism of Purification

Removing the Organic Template

In the initial processing stages, ethyl cellulose is mixed with talc to act as a stabilizer. While necessary for forming the nanosheets, this organic compound becomes an impurity in the final product.

The box furnace provides the thermal energy required to break down this chemical bond. It transitions the material from a composite mixture to a pure inorganic powder.

Controlled Thermal Decomposition

The furnace is set to a target temperature of 400°C. At this specific heat level, ethyl cellulose undergoes complete decomposition.

The "box" design of the furnace ensures a stable, uniform thermal environment. This uniformity is essential to ensure that the decomposition occurs evenly throughout the entire powder batch, preventing localized "cold spots" where organic residue might remain.

Impact on Material Properties

Achieving Chemical Purity

The ultimate goal of using the furnace is to produce pure talc nanosheet powders.

For sensitive applications, such as ionogel electrolytes, the presence of organic contaminants can severely hamper performance. The furnace ensures that the final powder is chemically clean and free of the ethyl cellulose precursor.

Controlling Nanosheet Size

Beyond simple purification, the annealing process helps define the physical characteristics of the powder.

The primary reference indicates that this heat treatment results in "size-controlled" nanosheets. By carefully removing the template at the correct rate and temperature, the furnace preserves the desired morphology of the talc.

Understanding the Trade-offs

Temperature Sensitivity

While 400°C is the target for this specific mixture, deviations can be problematic. If the temperature is too low, the ethyl cellulose will not decompose completely, leaving carbonaceous residue that contaminates the electrolyte.

Atmosphere Control

Laboratory box furnaces typically operate in air, which is effective for oxidizing and removing organics like ethyl cellulose.

However, unlike vacuum furnaces used for preventing oxidation in metals (such as bi-metal sintering), a standard box furnace allows for oxidation. This is beneficial here for burning off organics but requires that the talc itself remains stable in an oxygen-rich environment at that temperature.

Making the Right Choice for Your Goal

To maximize the effectiveness of your post-processing, focus on these operational priorities:

- If your primary focus is Chemical Purity: Ensure the furnace maintains 400°C for a sufficient duration to guarantee the total volatization of all ethyl cellulose content.

- If your primary focus is Electrolyte Performance: Verify that the "burn-off" process is complete, as even trace amounts of organic stabilizer can interfere with ionic conductivity in the final ionogel.

The box furnace is not just a heater; it is the final quality control gate that ensures your raw materials are chemically fit for advanced electronic applications.

Summary Table:

| Process Feature | Specification/Role | Impact on Talc Nanosheets |

|---|---|---|

| Target Temperature | 400°C | Ensures complete decomposition of organic binders |

| Mechanism | Thermal Annealing | Isolates inorganic talc from ethyl cellulose templates |

| Thermal Uniformity | Box Furnace Design | Prevents localized residue and ensures batch consistency |

| Atmosphere | Air/Oxidizing | Efficiently burns off organic stabilizers |

| End Result | High Chemical Purity | Optimizes nanosheets for ionogel electrolyte performance |

Elevate Your Material Purity with KINTEK

Precise temperature control is the difference between a contaminated sample and a high-performance nanosheet. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are performing delicate annealing or complex thermal decomposition, our laboratory high-temp furnaces are fully customizable to meet your unique research needs.

Ready to optimize your powder post-processing? Contact our technical experts today to find the perfect furnace solution for your lab.

Visual Guide

References

- Size‐Controlled Talc Nanosheet Ionogel Electrolytes for Dendrite Suppression in Solid‐State Sodium Metal Batteries. DOI: 10.1002/smsc.202500399

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why might a muffle furnace consume high energy? Tips to Cut Costs and Boost Efficiency

- What is the purpose of using a tube or muffle furnace for ZSM-5 zeolite calcination? Activate Your Catalyst Performance

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- How should alkaline substances be handled in a muffle furnace? Protect Your Equipment from Corrosion

- What are the common applications of benchtop furnaces? Unlock Precision in Materials Science and More

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- Why is it necessary to use a preheating furnace for SiC and B4C? Ensure Safety and Quality in Magnesium Composites

- What functions do muffle furnaces serve in the petrochemical industry? Essential Catalyst Prep and Quality Control