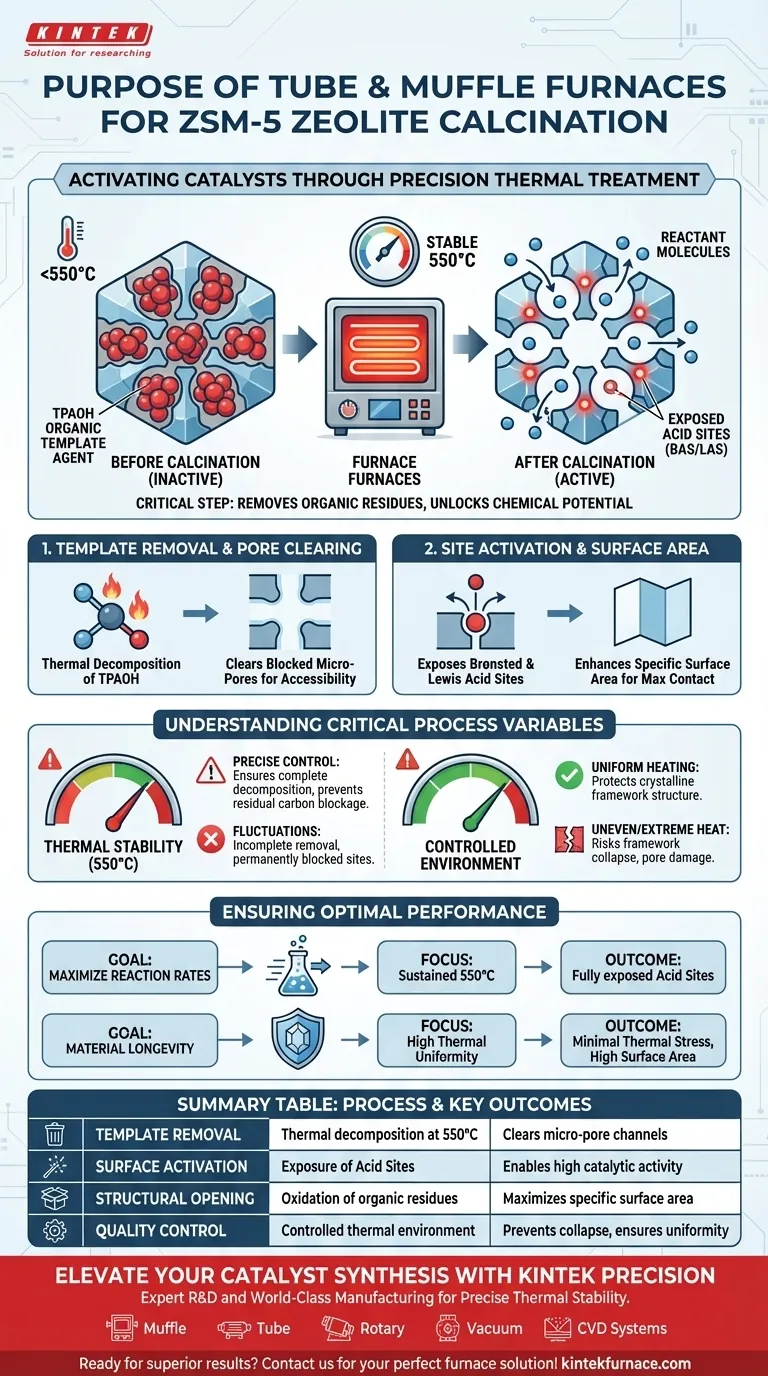

The primary purpose of using a tube or muffle furnace for the calcination of ZSM-5 zeolite catalysts is to provide a stable, high-temperature environment (typically 550 °C) required to activate the material. This thermal treatment is the critical step that transforms the synthesized raw material into a functional catalyst by removing organic residues.

By thermally decomposing the organic template agent, the furnace treatment clears blocked micro-pores and exposes the essential acid sites required for high catalytic activity and surface area.

The Mechanism of Template Removal

Thermal Decomposition of TPAOH

During the synthesis of ZSM-5, an organic template agent known as tetrapropylammonium hydroxide (TPAOH) is used to direct the structure. Once the structure is formed, this agent remains trapped inside the zeolite.

The furnace provides the necessary 550 °C heat to thermally decompose and oxidize this organic molecule. Without this high-temperature treatment, the template would remain, rendering the catalyst inert.

Clearing the Micro-Pore Channels

The physical removal of the TPAOH is essential for accessibility. The organic template acts as a plug, blocking the intricate network of channels within the zeolite.

Calcination burns these "plugs" away, effectively opening the micro-pores. This ensures that reactant molecules can freely enter and exit the catalyst's internal structure during future applications.

Activation of Catalytic Sites

Exposing Acid Sites

The true value of ZSM-5 lies in its chemical properties, specifically its acidity. The furnace treatment does more than just create empty space; it exposes active acid sites.

Specifically, the process reveals Brønsted and Lewis acid sites (BAS/LAS). These sites are the active centers where chemical reactions occur, making their exposure vital for the catalyst's performance.

Enhancing Specific Surface Area

A direct result of clearing the pores and exposing these sites is a dramatic increase in the material's specific surface area.

A large specific surface area allows for maximum contact between the catalyst and reactants. This is the defining characteristic of a high-efficiency ZSM-5 catalyst.

Understanding Critical Process Variables

The Importance of Thermal Stability

While the target temperature is 550 °C, the stability of the furnace environment is just as important as the temperature itself.

Fluctuations in temperature can lead to incomplete decomposition of the TPAOH. Residual carbon or organic matter left in the pores will permanently block active sites and reduce catalytic efficiency.

Preventing Structural Damage

The furnace must provide a controlled environment to ensure the zeolite framework remains intact.

If the temperature is not maintained precisely, or if the heating is uneven, there is a risk of damaging the crystalline structure. This would collapse the very pores you are attempting to clear, negating the benefits of the treatment.

Ensuring Optimal Catalyst Performance

To achieve the best results in ZSM-5 synthesis, align your furnace operation with your specific performance goals:

- If your primary focus is maximizing reaction rates: Ensure the furnace maintains a sustained 550 °C to guarantee the complete removal of TPAOH, fully exposing the Brønsted and Lewis acid sites.

- If your primary focus is material longevity: Prioritize a furnace with high thermal uniformity to clear micro-pores without inducing thermal stress that could degrade the specific surface area.

The furnace is not merely a heating device; it is the tool that unlocks the chemical potential of the ZSM-5 zeolite.

Summary Table:

| Process Objective | Mechanism | Key Outcome |

|---|---|---|

| Template Removal | Thermal decomposition of TPAOH at 550°C | Clears blocked micro-pore channels |

| Surface Activation | Exposure of Brønsted & Lewis acid sites | Enables high catalytic activity |

| Structural Opening | Oxidation of organic residues | Maximizes specific surface area |

| Quality Control | Controlled thermal environment | Prevents framework collapse & ensures uniformity |

Elevate Your Catalyst Synthesis with KINTEK Precision

Don't let temperature fluctuations compromise your ZSM-5 catalyst's activity. At KINTEK, we understand that precise thermal stability is the key to unlocking the full potential of your zeolite frameworks.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temperature furnaces are fully customizable to meet your unique calcination protocols, ensuring uniform heating that protects your material's crystalline structure while maximizing specific surface area.

Ready to achieve superior catalytic results? Contact us today to find the perfect furnace solution for your lab!

Visual Guide

References

- Wei Xiong, Jun Zhao. Acidic Site-Controlled ZSM-5 Catalysts for Fast Molten-Phase Pyrolysis of Plastic Waste with Tunable Product Distribution. DOI: 10.1021/acs.energyfuels.5c02781

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability