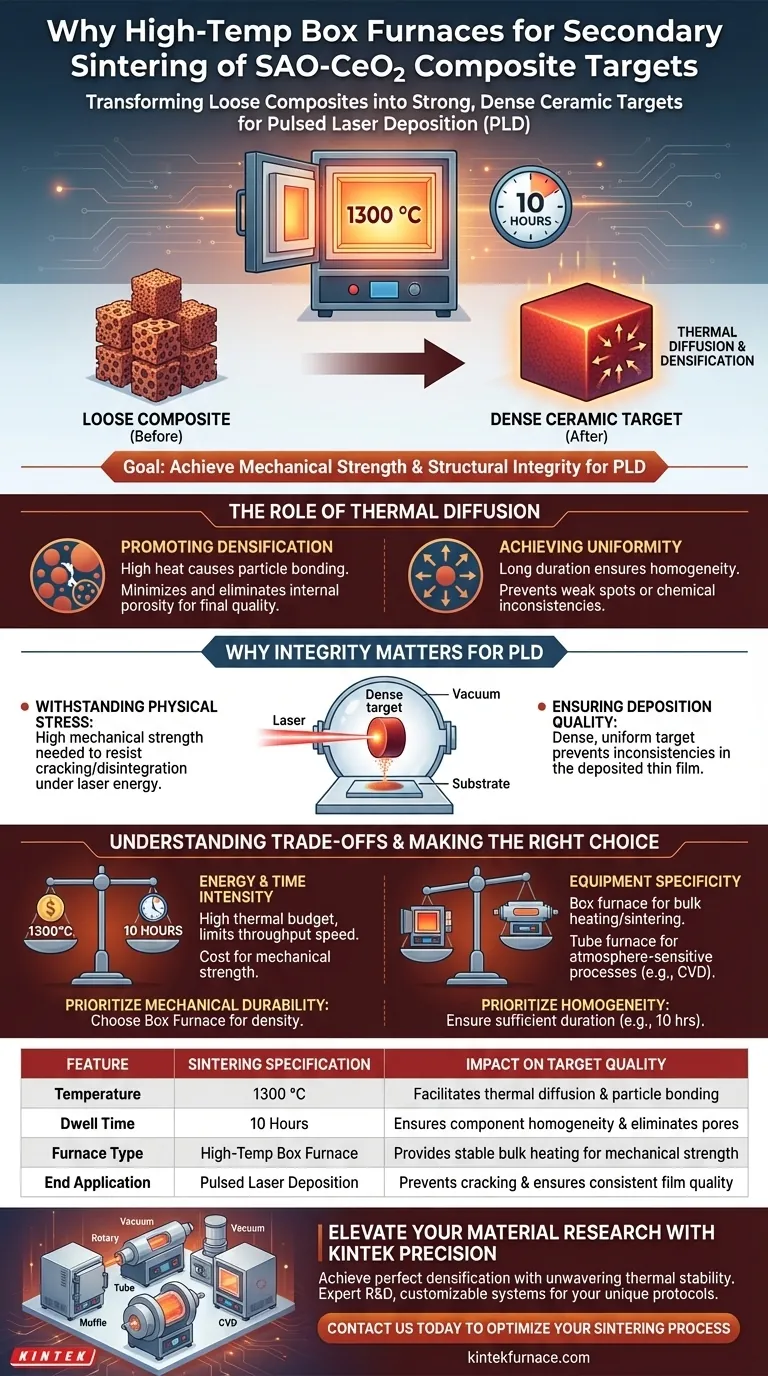

A high-temperature box furnace is utilized for the secondary sintering of SAO-CeO2 composite targets primarily to drive densification and structural uniformity through sustained heat. By maintaining a temperature of 1300 °C for 10 hours, the furnace facilitates thermal diffusion, effectively eliminating internal pores and ensuring the ceramic components are evenly distributed.

The core purpose of using this furnace is to transform a loose composite into a mechanically strong, dense ceramic target capable of withstanding the rigors of Pulsed Laser Deposition (PLD) processes.

The Role of Thermal Diffusion in Sintering

Promoting Densification

The primary function of the high-temperature box furnace in this context is to create a dense material.

Through the mechanism of thermal diffusion, the high heat causes the particles within the SAO-CeO2 composite to bond closer together. This process systematically minimizes and eliminates internal porosity, which is critical for the target's final quality.

Achieving Component Uniformity

Beyond simple densification, the long duration of the sinter (10 hours) ensures homogeneity.

The sustained heat allows the ceramic components to distribute uniformly throughout the target. This prevents weak spots or chemical inconsistencies that could degrade the performance of the material during subsequent applications.

Why Material Integrity Matters for PLD

Withstanding Physical Stress

The end goal of this sintering process is to produce a target suitable for Pulsed Laser Deposition (PLD).

PLD is a physically demanding process that requires the source material to possess high mechanical strength. Without the deep sintering provided by the box furnace, the target could crack or disintegrate under the laser's energy.

Ensuring Deposition Quality

The quality of the thin film produced by PLD is directly dependent on the quality of the target.

A target with internal pores or uneven component distribution can lead to inconsistencies in the deposited film. The box furnace ensures the target is dense and uniform enough to yield a high-quality deposition.

Understanding the Trade-offs

Energy and Time Intensity

While the box furnace is essential for densification, it is a resource-intensive method.

Running a cycle at 1300 °C for 10 hours requires significant energy and limits the throughput speed of manufacturing. This high thermal budget is the cost of achieving the necessary mechanical strength.

Equipment Specificity

It is important to distinguish the utility of the box furnace from other high-temperature equipment.

While a box furnace is ideal for the bulk heating and sintering required here, it differs from equipment like tube furnaces, which are typically used for atmosphere-sensitive processes like Chemical Vapor Deposition (CVD). Selecting the wrong furnace type can lead to poor atmosphere control or uneven heating for large bulk targets.

Making the Right Choice for Your Goal

When preparing composite targets, the equipment must match the desired material properties.

- If your primary focus is mechanical durability: Prioritize a high-temperature box furnace cycle to maximize density and prevent fracturing during PLD.

- If your primary focus is material homogeneity: Ensure the sintering duration is sufficient (e.g., 10 hours) to allow for complete thermal diffusion of the ceramic components.

By leveraging the sustained, high-heat environment of a box furnace, you ensure your SAO-CeO2 targets achieve the structural integrity required for high-performance applications.

Summary Table:

| Feature | Sintering Specification | Impact on Target Quality |

|---|---|---|

| Temperature | 1300 °C | Facilitates thermal diffusion and particle bonding |

| Dwell Time | 10 Hours | Ensures component homogeneity and eliminates pores |

| Furnace Type | High-Temp Box Furnace | Provides stable bulk heating for mechanical strength |

| End Application | Pulsed Laser Deposition | Prevents cracking and ensures consistent film quality |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect densification for SAO-CeO2 targets requires equipment that delivers unwavering thermal stability. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered to meet the rigorous demands of modern material science.

Whether you need standard high-temperature box furnaces or fully customizable systems tailored to your unique sintering protocols, our expert R&D and manufacturing teams are here to support your laboratory's success. Ensure your targets withstand the rigors of PLD with KINTEK’s reliable heating technology.

Ready to optimize your sintering process? Contact us today to consult with our technical experts!

Visual Guide

References

- Benson Kunhung Tsai, Haiyan Wang. CeO<sub>2</sub> Nanostructures Prepared by Selective Water‐Soluble Sr<sub>3</sub>Al<sub>2</sub>O<sub>6</sub>(SAO)‐CeO<sub>2</sub> Vertically Aligned Nanocomposite. DOI: 10.1002/adem.202500530

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does heating rate control within a muffle furnace impact activated carbon? Optimize Yield and Pore Structure

- How does muffle furnace calcination at 900°C for 13 hours form P2-type cathode structures?

- How does a muffle furnace ensure precise temperature control? Discover the Key Components for Accurate Heating

- What should be considered regarding the controller when purchasing a muffle furnace? Choose the Right Controller for Precision

- What are the steps for setting up a muffle furnace before use? Ensure Safety and Accuracy in Your Lab

- How does Spark Plasma Sintering (SPS) compare to traditional muffle furnace sintering? Achieve Fine-Grained Ceramics

- How are muffle furnaces used in glassmaking? Achieve Clean, Controlled Heat for Superior Glass Quality

- Why are muffle furnaces considered indispensable in laboratory and industrial settings? Discover Their Key Benefits for Clean, Controlled Heating