Setting up a muffle furnace is a methodical process that goes beyond simply plugging it in. It involves three distinct phases: correct physical installation, critical pre-use conditioning, and adherence to strict operational protocols to ensure both safety and the longevity of the equipment.

The core principle of furnace setup is to establish a safe, stable, and accurate operating environment. Neglecting initial steps like proper grounding or the mandatory drying procedure can lead to inaccurate results, equipment damage, or serious safety hazards.

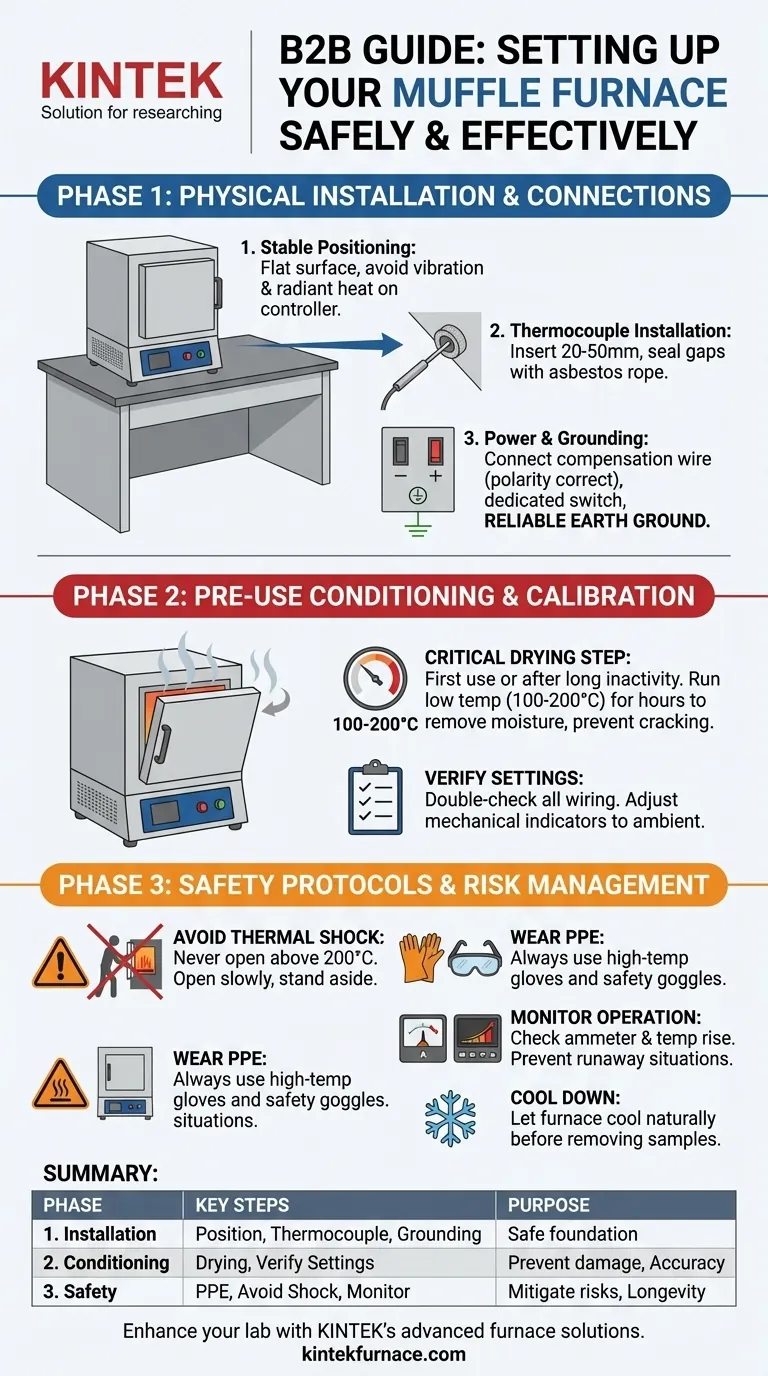

Phase 1: Physical Installation and Electrical Connections

The initial setup creates the foundation for all future work. Getting these physical and electrical connections right is non-negotiable for safe operation.

Position the Furnace Correctly

Place the furnace on a completely flat and stable surface. The temperature controller unit must be positioned to avoid exposure to vibration or radiant heat from the furnace itself, as this can affect its accuracy and lifespan.

Install the Thermocouple

The thermocouple is the furnace's nerve center. Insert its tip approximately 20-50mm into the furnace chamber through the designated port.

Use the provided asbestos rope or similar refractory material to seal any gaps around the thermocouple. This prevents heat loss and ensures an accurate temperature reading of the chamber's interior.

Ensure Safe Power and Grounding

Connect the thermocouple to the controller using the specified compensation wire, paying close attention to the correct polarity (+ and -). An incorrect connection will result in faulty temperature readings.

For safety, the main power line must have a dedicated power switch installed upstream of the furnace. Most importantly, you must verify that the furnace has a reliable earth ground connection to prevent electrical shock hazards.

Phase 2: Pre-Use Conditioning and Calibration

Before you heat your first sample, the furnace itself needs to be prepared. This conditioning phase is crucial for accuracy and preventing damage.

The Critical Drying Step

If you are using the furnace for the first time or after a long period of inactivity, it must be dried. Moisture can accumulate in the refractory lining, and rapid heating can cause this moisture to turn to steam, cracking the insulation.

To dry the furnace, run it at a low temperature (e.g., 100-200°C) for several hours with the door slightly ajar to allow moisture to escape.

Verify Settings and Connections

Before applying power, double-check all wiring connections. If your model has a mechanical thermometer indicator, adjust it to the ambient temperature (or zero) before starting.

Understanding the Risks and Safety Protocols

A muffle furnace is not a simple oven; it operates at extreme temperatures and carries inherent risks if mismanaged.

Risk of Thermal Shock

The refractory materials and heating elements inside the furnace are susceptible to thermal shock. Never open the furnace door when the internal temperature is above 200°C unless absolutely necessary.

When you do open the door, do so slowly and stand to the side. A sudden rush of cool air can crack the hot interior, and a blast of superheated air can cause severe burns.

The Hazard of High Temperatures

Always wear appropriate Personal Protective Equipment (PPE), including high-temperature gloves and safety goggles, when handling items or opening the furnace.

After an experiment is complete, turn off the power and let the furnace cool down naturally. Do not attempt to remove your sample until the temperature has fallen to a safe level.

Monitoring for System Failure

During operation, you should periodically confirm that the furnace is working as expected. A reading on the ammeter and a steadily increasing temperature on the controller are good indicators.

Be aware that automatic temperature controllers can fail. You should remain in the vicinity of an operating furnace to prevent a runaway temperature situation that could destroy the heating elements or the furnace itself.

A Checklist for Safe Operation

Use this guidance to tailor your setup procedure to the situation.

- If this is the very first use: Follow every step meticulously, paying special attention to the physical installation, grounding, and the mandatory initial drying procedure.

- If you are starting a routine daily process: Your primary checks are to ensure the controller is set correctly, the door is closed, and you follow all cooldown and PPE safety rules.

- If the furnace has been inactive for weeks or months: Always perform the pre-use drying step again before running a high-temperature program to protect the internal refractory materials.

Following these deliberate steps will ensure your muffle furnace operates safely, accurately, and reliably for years to come.

Summary Table:

| Phase | Key Steps | Purpose |

|---|---|---|

| 1: Physical Installation | Position on stable surface, install thermocouple, ensure grounding | Establish safe and stable foundation |

| 2: Pre-Use Conditioning | Perform drying step, verify settings and connections | Prevent damage and ensure accuracy |

| 3: Safety Protocols | Wear PPE, avoid thermal shock, monitor operation | Mitigate risks and maintain equipment longevity |

Need a reliable high-temperature furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and safety with our tailored furnace solutions!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the necessity of cleaning and drying activated carbon supports in a muffle furnace? Unlock Peak Catalyst Performance

- What temperature considerations are important for muffle furnaces? Optimize Performance and Longevity

- How is economical operation achieved in Box Furnaces? Cut Costs with Efficient Thermal Engineering

- What materials are used in the construction of muffle furnaces to ensure durability? Discover the Key Components for Long-Lasting Performance

- What is the function of a high-temperature box furnace in the annealing process of AA6061 aluminum alloy?

- What are the advantages of modern muffle furnaces compared to older models? Discover Precision, Efficiency, and Reliability

- Why is precise temperature control important in a muffle furnace? Ensure Reliable Results in Heat Treatment

- What is the most common format for Controlled Atmosphere Continuous Muffle Furnaces? Belt Furnace for High-Throughput Processing