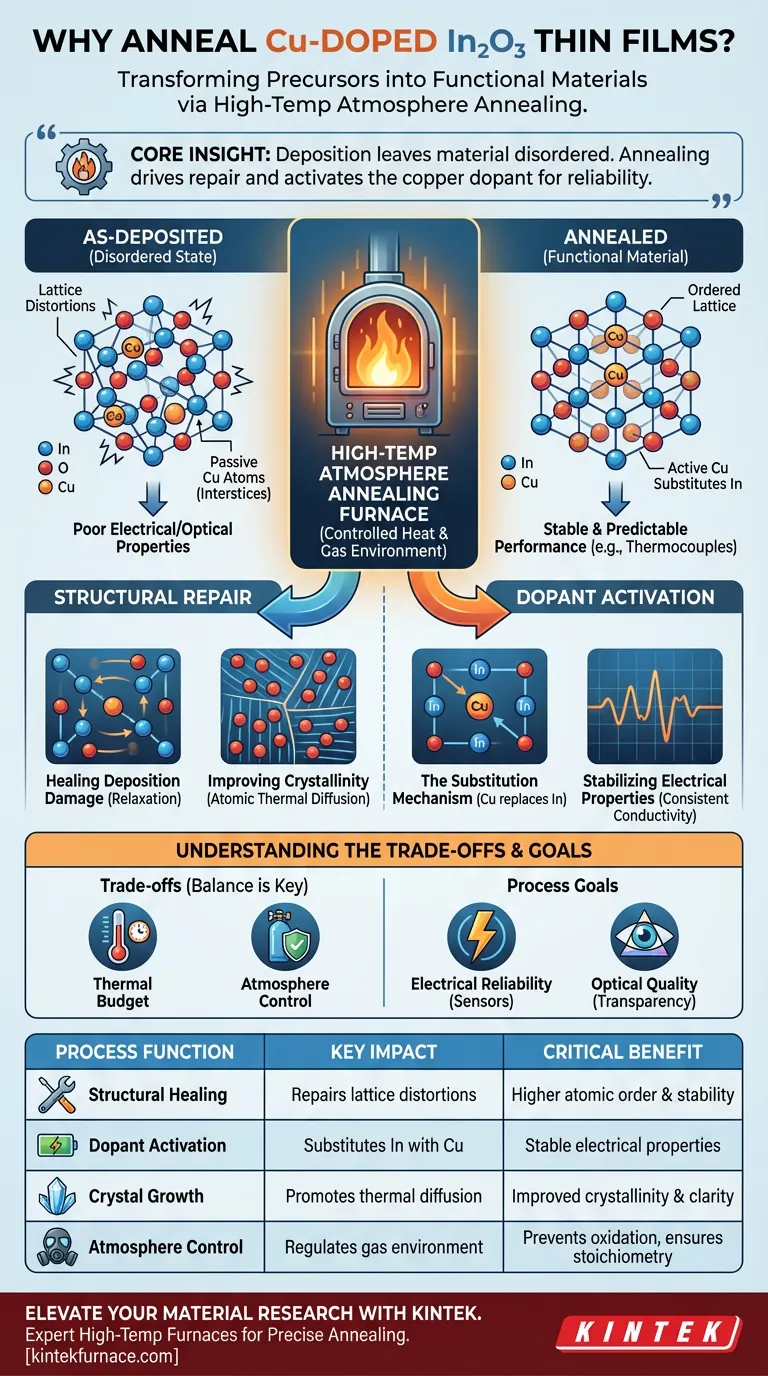

A high-temperature atmosphere annealing furnace acts as the critical activation step that transforms a deposited precursor into a functional material. Its primary purpose for copper-doped indium oxide (Cu-doped In2O3) is to provide the thermal energy required to repair atomic damage caused by deposition and to force copper atoms into the correct structural positions. Without this thermal treatment, the film lacks the necessary electrical stability and optical clarity.

Core Insight: The deposition process leaves the material in a disordered state; annealing is the "fix." It drives atomic diffusion to repair lattice distortions and chemically activates the copper dopant by substituting it into the indium sites, thereby locking in the material's reliability for high-precision uses like thermocouples.

The Mechanics of Structural Repair

Healing Deposition Damage

During sputtering or deposition, high-energy particles impact the substrate, often creating a chaotic atomic structure. This results in lattice distortions—imperfections in the crystal structure that impede electron flow and reduce performance. The furnace provides controlled thermal energy, allowing atoms to relax back into their lowest-energy, ordered states, effectively "healing" the damage.

Improving Crystallinity

A highly crystalline film typically exhibits superior electronic properties compared to an amorphous or disordered one. High-temperature annealing promotes atomic thermal diffusion, which reorganizes the atoms into a cohesive, repeating crystal lattice. This structural alignment is fundamental to ensuring the film behaves consistently under electrical load.

Activating the Dopant

The Substitution Mechanism

For copper doping to be effective, copper atoms cannot simply sit in the gaps (interstices) of the material. They must physically replace indium atoms within the lattice structure. The annealing furnace supplies the precise activation energy needed to facilitate this substitution of indium atoms by copper atoms, turning the copper from a passive impurity into an active functional component.

Stabilizing Electrical Properties

Once the copper is correctly substituted into the lattice, the electronic behavior of the film stabilizes. This process eliminates fluctuations in conductivity that might occur in an unannealed sample. This stability is particularly vital for applications like thermocouple electrodes, where predictable performance under varying conditions is non-negotiable.

Understanding the Trade-offs

Thermal Budget Management

While heat is necessary for repair, it must be carefully balanced. Insufficient heat (time or temperature) will leave the copper inactive and the lattice distorted, resulting in poor conductivity. Conversely, excessive heat can lead to unwanted grain growth or diffusion of atoms between the film and the substrate, potentially degrading the interface.

Atmosphere Control

The "atmosphere" component of the furnace is just as critical as the temperature. The specific gas environment (often controlled to prevent unwanted oxidation or reduction) ensures that the film stoichiometry remains pure during the heating process. Precise regulation is required to prevent surface contamination or the loss of volatile components.

Making the Right Choice for Your Goal

When designing your post-deposition process, focus on the end-use requirements of your thin film.

- If your primary focus is Electrical Reliability: Prioritize annealing schedules that maximize the substitution of Indium with Copper to ensure stable conductivity for sensors or electrodes.

- If your primary focus is Optical Quality: Focus on repairing lattice distortions to minimize scattering and improve the film's transparency and crystallinity.

Ultimately, the annealing furnace is not just a heating tool; it is a reactor that defines the final quality and utility of your thin film.

Summary Table:

| Process Function | Key Impact on Thin Film | Critical Benefit |

|---|---|---|

| Structural Healing | Repairs lattice distortions from sputtering | Higher atomic order and stability |

| Dopant Activation | Substitutes Indium atoms with Copper atoms | Stable and predictable electrical properties |

| Crystal Growth | Promotes atomic thermal diffusion | Improved crystallinity and optical clarity |

| Atmosphere Control | Regulates gas environment during heating | Prevents oxidation and ensures stoichiometry |

Elevate Your Material Research with KINTEK

Precise annealing is the difference between a disordered precursor and a high-performance functional material. At KINTEK, we understand that your thin-film reliability depends on exact thermal and atmospheric control. Backed by expert R&D and manufacturing, we offer high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of dopant activation and lattice repair.

Ready to optimize your thin-film properties? Contact us today to discover how our specialized lab high-temp furnaces can bring superior stability and clarity to your advanced materials.

Visual Guide

References

- Yantao Liu, Sui Chen. Analysis of the Effect of Copper Doping on the Optoelectronic Properties of Indium Oxide Thin Films and the Thermoelectric Properties of an In2O3/Pt Thermocouple. DOI: 10.3390/cryst14010078

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are some examples of inert gases used in inert atmospheres? Optimize Your Process with Nitrogen or Argon

- How do atmosphere control systems contribute to furnace operation? Unlock Precision and Quality in Material Processing

- What are the key benefits of precise temperature control in a controlled atmosphere furnace? Unlock Superior Quality and Efficiency

- Why is a high-precision isothermal furnace required for ADI heat treatment? Ensure High-Performance Microstructures

- How does a box type atmosphere furnace achieve precise atmosphere control? Discover Key Systems for Reliable Heat Treatment

- How does the experimental box type atmosphere furnace ensure accurate atmosphere control? Master Precise Gas Management for Reliable Results

- What role does an atmosphere furnace play in industrial-scale production? Unlock Precision in High-Temperature Processing

- What key conditions does a tube atmosphere furnace provide for nanosheet coatings? Optimize Your Heat Treatment Result