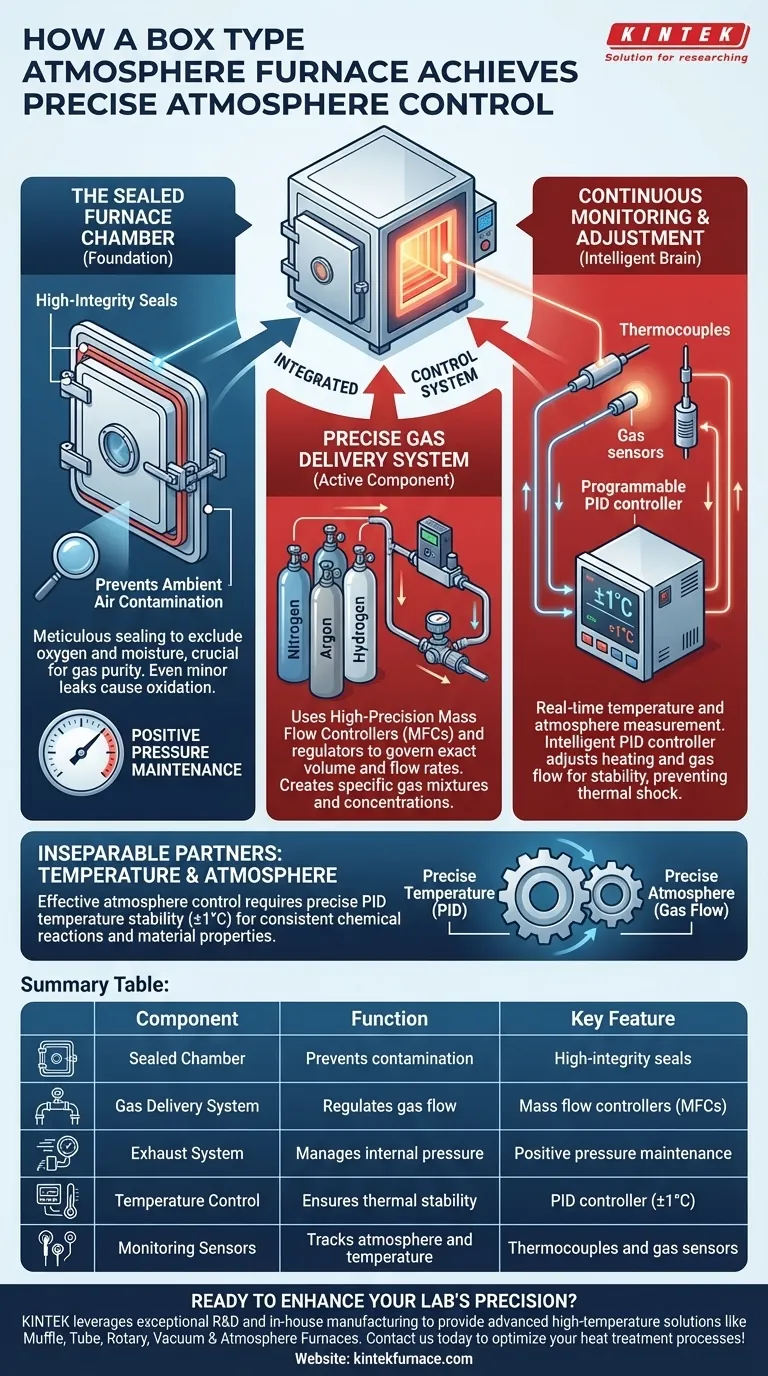

At its core, a box type atmosphere furnace achieves precise atmosphere control through an integrated system that manages three critical factors: the structural integrity of the sealed chamber, the precise delivery of specific gases, and the continuous monitoring and adjustment of the internal environment. By combining high-integrity construction with advanced gas flow hardware and intelligent control loops, the furnace creates a highly stable and repeatable processing environment isolated from outside air.

The precision of an atmosphere furnace is not the result of a single component, but rather a system working in concert. It relies on a physically sealed chamber to prevent contamination, precision hardware to control the gas inputs, and intelligent sensors to maintain a stable internal state.

The Core Components of Atmosphere Control

To understand how precision is achieved, we must look at the key systems that work together. The failure of any one component compromises the entire process.

The Sealed Furnace Chamber

The foundation of atmosphere control is the physical enclosure. The chamber must be meticulously sealed to prevent ambient air, particularly oxygen and moisture, from leaking in and contaminating the process.

This seal integrity is crucial for maintaining the desired gas purity. Even a minor leak can introduce contaminants that lead to unwanted oxidation or failed chemical reactions at high temperatures.

The Gas Delivery System

This system is the active component of atmosphere control. It uses specialized hardware to introduce and regulate the gases inside the chamber.

High-precision mass flow controllers (MFCs) and pressure regulators are used to govern the exact volume and flow rate of each gas, such as nitrogen, argon, or hydrogen. This allows for the creation of specific gas mixtures and concentrations required for the treatment process.

The Exhaust and Pressure Management

Control is not just about pumping gas in. The furnace must also manage its internal pressure and exhaust.

A slight positive pressure is typically maintained inside the chamber. This ensures that if any microscopic leaks exist, the internal atmosphere gas flows outward, preventing ambient air from flowing inward and ensuring a pure environment.

Why Temperature Control is Inseparable from Atmosphere

A perfectly controlled atmosphere is only effective when paired with equally precise temperature control. The chemical reactions and material properties targeted by heat treatment are dependent on both variables.

High-Precision Temperature Sensing

Furnaces use sensitive thermocouples to measure the internal temperature in real-time. The accuracy and placement of these sensors are critical for providing reliable data to the control system.

Intelligent PID Control

This data is fed to a programmable PID (Proportional-Integral-Derivative) controller. A PID controller is an intelligent algorithm that constantly adjusts the power to the heating elements.

Its function is to reach the target temperature smoothly without overshooting and then hold that temperature with minimal fluctuation, often achieving stability as tight as ±1°C. This prevents the thermal shocks and variations that could ruin a sensitive process.

Understanding the Trade-offs and Pitfalls

While highly effective, achieving and maintaining precise atmosphere control involves practical considerations and potential points of failure.

Seal Integrity and Maintenance

The gaskets and seals that ensure the chamber's integrity are consumable parts. They degrade over time with thermal cycling and must be regularly inspected and replaced to prevent atmosphere contamination.

Gas Purity and Cost

The precision of the furnace is rendered useless if the source gas is impure. Using high-purity gases is essential but adds to the operational cost, especially for inert gases like argon.

Purging Time vs. Throughput

Before a heating cycle can begin, the furnace chamber must be purged of ambient air and filled with the desired process gas. This purging cycle takes time and can be a bottleneck in high-throughput production environments.

Making the Right Choice for Your Process

Understanding these systems allows you to align a furnace's capabilities with your specific goal.

- If your primary focus is preventing oxidation (e.g., bright annealing): The key is ensuring excellent seal integrity and maintaining a consistent positive pressure with an inert gas like nitrogen.

- If your primary focus is specific chemical reactions (e.g., carburizing): The critical factor is the accuracy and responsiveness of the gas mixing system, specifically the mass flow controllers.

- If your primary focus is high-repeatability research: The most important aspect is the tight integration of PID temperature stability and atmosphere control, coupled with robust data logging.

By appreciating how these systems work together, you can ensure your heat treatment process is both precise and reliable.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Sealed Chamber | Prevents contamination | High-integrity seals |

| Gas Delivery System | Regulates gas flow | Mass flow controllers (MFCs) |

| Exhaust System | Manages internal pressure | Positive pressure maintenance |

| Temperature Control | Ensures thermal stability | PID controller (±1°C) |

| Monitoring Sensors | Tracks atmosphere and temperature | Thermocouples and gas sensors |

Ready to enhance your lab's precision with a custom atmosphere furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures your unique experimental needs are met. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process