At its core, an experimental box type atmosphere furnace ensures accuracy by treating the internal atmosphere as a complete, managed system. This is achieved by first creating a perfectly sealed environment and then using high-precision components to precisely dose, mix, and regulate the flow and pressure of specific gases like argon, nitrogen, or reducing mixtures.

The accuracy of an atmosphere furnace is not a single feature but the result of a coordinated system. It depends on the integrity of the furnace seal, the precision of its gas flow and pressure controllers, and the stability of its temperature management system working in unison.

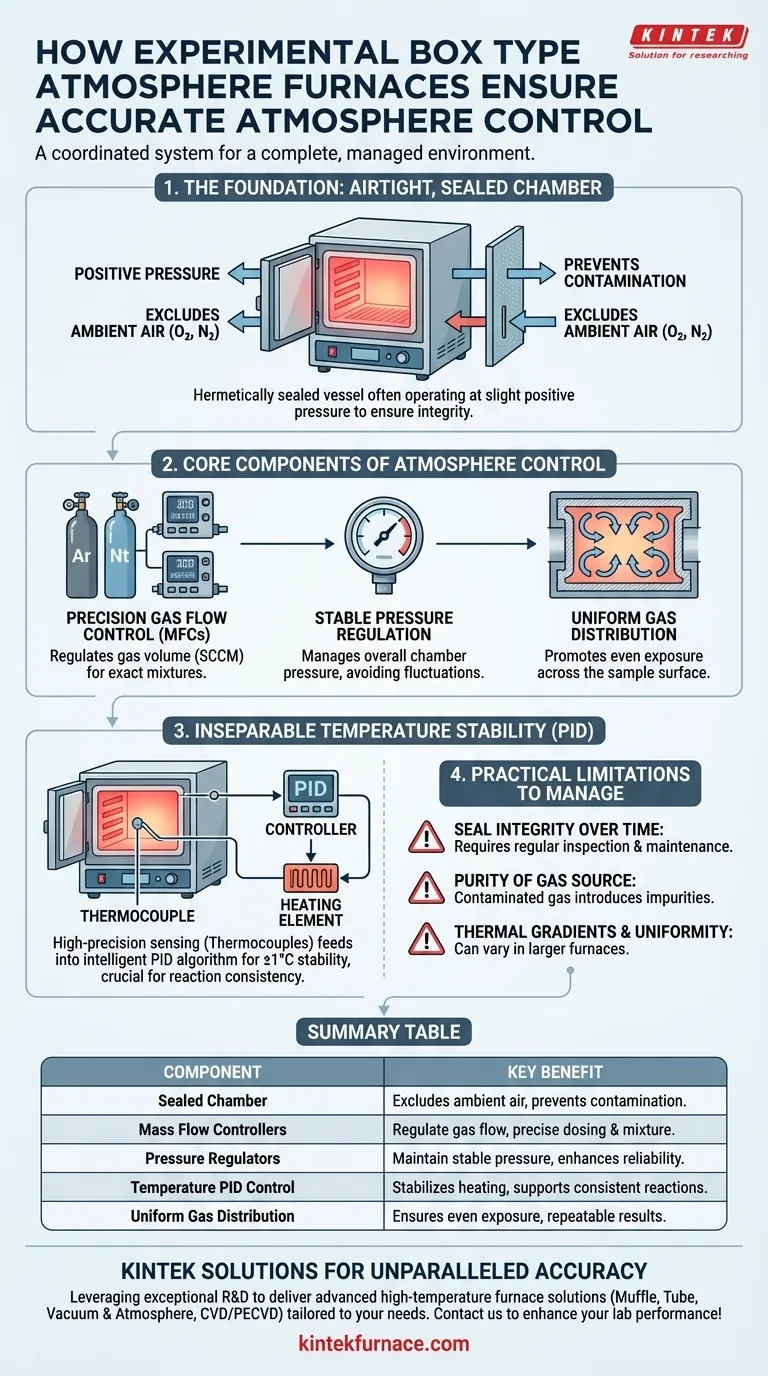

The Foundation: An Airtight, Sealed Chamber

Before any atmosphere can be controlled, the outside atmosphere must be completely excluded. This is the non-negotiable first principle of atmospheric control.

The Importance of the Seal

The furnace chamber is engineered to be a hermetically sealed vessel. This prevents ambient air, primarily oxygen and nitrogen, from leaking into the chamber at high temperatures and contaminating the process.

Without a perfect seal, any gas you introduce would be compromised, leading to unwanted oxidation or unpredictable chemical reactions.

Achieving a Positive Pressure Environment

To further guarantee against contamination, these furnaces often operate at a slight positive pressure. By maintaining an internal pressure slightly higher than the outside air, any potential micro-leaks will cause the controlled atmosphere to flow out, rather than allowing air to seep in.

The Core Components of Atmosphere Control

Once the chamber is sealed, a set of precision components works to create and maintain the desired gas environment.

Precision Gas Flow Control

The system uses high-precision mass flow controllers (MFCs) or gas flow meters. These devices are critical for accurately regulating the volume of gas entering the furnace, measured in units like Standard Cubic Centimeters per Minute (SCCM).

This allows you to control not only the type of gas but also its exact concentration and flow rate, which is essential for processes that rely on specific gas mixtures or purge cycles.

Stable Pressure Regulation

In tandem with flow controllers, pressure regulating devices ensure the stability of the internal atmosphere. They manage the overall pressure within the chamber, preventing fluctuations that could affect reaction rates or the physical integrity of the sample.

Uniform Gas Distribution

A well-designed furnace includes an inlet and outlet system that promotes uniform gas distribution. The goal is to avoid static pockets and ensure the entire sample is exposed to the same atmospheric conditions, ensuring consistent and repeatable results across its surface.

Why Temperature Control is Inseparable from Atmosphere Control

While your question focuses on atmosphere, it's impossible to discuss it without acknowledging the role of temperature. Chemical reactions and material phase changes are dependent on both.

High-Precision Temperature Sensing

The furnace uses sensitive thermocouples to measure the internal temperature in real-time. This raw data is the basis for all temperature regulation.

Intelligent PID Adjustment

The temperature signal is fed to an intelligent controller that uses a Proportional-Integral-Derivative (PID) algorithm. This algorithm continuously calculates the difference between the setpoint and the actual temperature, precisely adjusting the heating element's power to maintain exceptional stability, often within ±1°C.

This stability is crucial because even minor temperature fluctuations can dramatically alter the rate of atmospheric reactions, rendering precise gas control ineffective.

Understanding the Practical Limitations

Achieving a perfect atmosphere is a technical challenge, and it's important to understand the potential points of failure.

Seal Integrity Over Time

Door seals, gaskets, and feedthroughs for sensors can degrade over time with thermal cycling. Regular inspection and maintenance are critical to prevent leaks that would compromise the entire system.

Purity of the Gas Source

The control system is only as good as the gas you supply it with. Using a low-purity gas source or having contaminated gas lines will introduce impurities directly into your process, regardless of how precise the furnace controllers are.

Thermal Gradients and Uniformity

In larger furnaces, achieving perfect atmospheric and thermal uniformity can be difficult. The center of the furnace may have slightly different conditions than the areas near the walls or door, which can be a factor in highly sensitive processes.

Making the Right Choice for Your Goal

To select the right system, you must match the furnace's capabilities to your experimental or production requirements.

- If your primary focus is preventing oxidation (e.g., bright annealing): Prioritize a furnace with a certified low leak rate and the ability to maintain stable, positive pressure with an inert gas.

- If your primary focus is driving specific surface reactions (e.g., carburizing): You need a system with high-precision mass flow controllers for multiple gases to create and hold exact mixture ratios.

- If your primary focus is general research with various materials: A furnace with a good seal and reliable, single-gas flow control provides the best balance of capability and operational simplicity.

Understanding how these systems work together empowers you to control your process environment, ensuring the reliability and repeatability of your results.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Sealed Chamber | Excludes ambient air | Prevents contamination and ensures purity |

| Mass Flow Controllers | Regulate gas flow and concentration | Enables precise dosing and mixture control |

| Pressure Regulators | Maintain stable internal pressure | Avoids fluctuations and enhances reliability |

| Temperature PID Control | Stabilizes heating | Supports consistent atmospheric reactions |

| Uniform Gas Distribution | Ensures even exposure | Provides repeatable results across samples |

Ready to achieve unparalleled accuracy in your experiments? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on preventing oxidation, driving specific reactions, or general research, our furnaces ensure reliable atmosphere control for consistent outcomes. Contact us today to discuss how we can enhance your laboratory's performance!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality