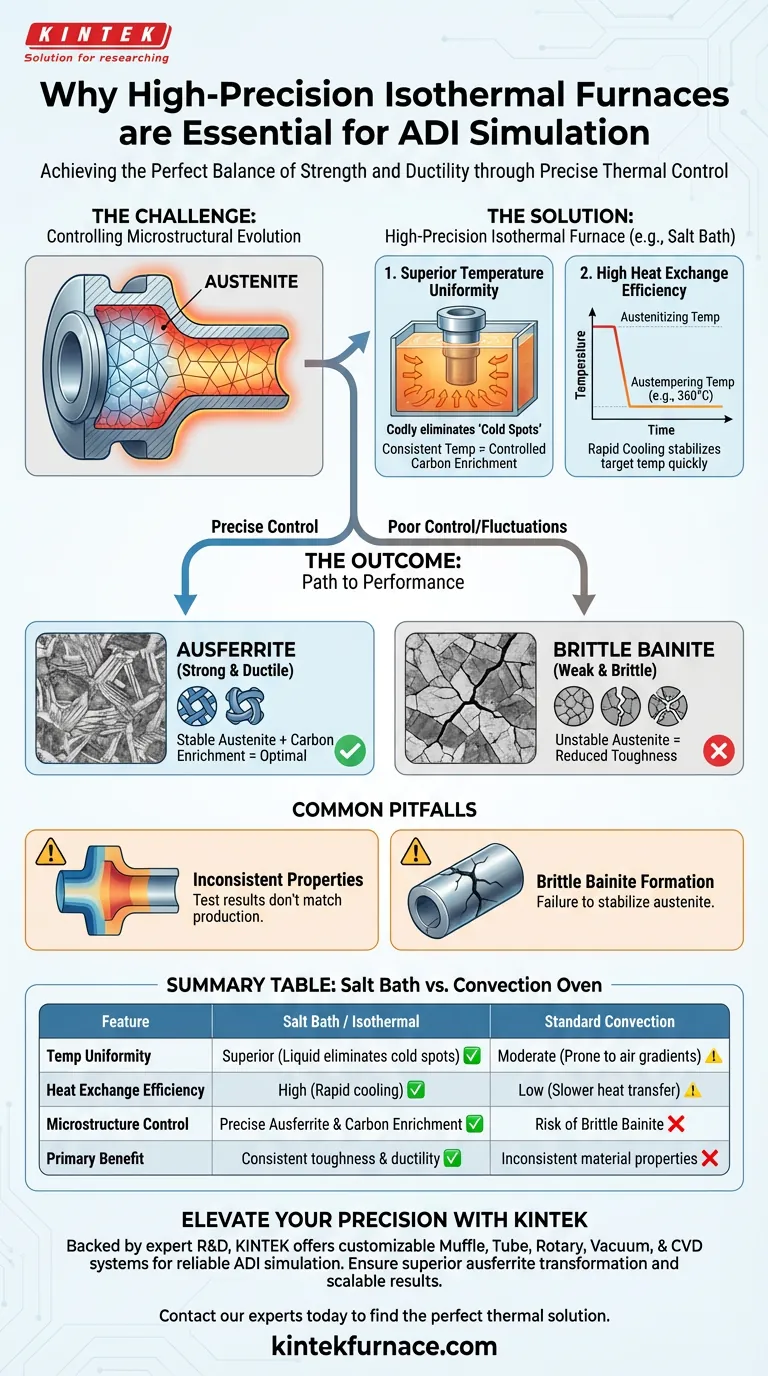

A high-precision isothermal furnace, particularly an industrial salt bath, is required for simulating Austempered Ductile Iron (ADI) heat treatment because it delivers superior temperature uniformity and high heat exchange efficiency. This precise thermal environment is the only way to accurately control the transformation of the metal's microstructure, ensuring the material achieves the specific balance of strength and ductility rather than becoming brittle.

The core capability of an isothermal furnace is its ability to lock in a specific temperature, such as 360 °C, without fluctuation. This stability controls the carbon enrichment of austenite, which is the defining factor in preventing brittle bainite and successfully forming high-performance ausferrite.

The Physics of Precision Heat Treatment

Achieving Superior Temperature Uniformity

In ADI processing, the entire component must be held at the exact same temperature simultaneously.

An industrial salt bath excels at this because the liquid medium surrounds the part completely. This eliminates "cold spots" or gradients that often occur in standard convection ovens.

High Heat Exchange Efficiency

Speed is as critical as stability. The transition from the austenitizing temperature to the austempering temperature must happen rapidly.

Salt baths provide high heat exchange efficiency, rapidly extracting heat from the part to stabilize it at the target temperature. This rapid cooling creates the necessary conditions for the desired phase transformation to begin.

Controlling Microstructural Evolution

Determining the Degree of Transformation

The ultimate goal of this process is to convert the metal's structure from austenite to ausferrite.

The degree of this transformation is dictated entirely by how well the isothermal conditions are maintained. Precision equipment ensures the transformation stops exactly when the optimal properties are reached.

Regulating Carbon Enrichment

During the hold time at a constant temperature (e.g., 360 °C), carbon diffuses into the remaining austenite.

This carbon enrichment stabilizes the austenite, making it tough and ductile. If the temperature fluctuates, this diffusion becomes unpredictable, compromising the material's integrity.

Common Pitfalls to Avoid

The Formation of Brittle Bainite

If the furnace cannot maintain strict isothermal control, the process fails to stabilize the austenite correctly.

This failure allows the formation of brittle bainite, a microstructure that significantly reduces the toughness of the iron.

Inconsistent Mechanical Properties

Without a high-precision furnace, you risk achieving different properties in different areas of the same part.

This inconsistency renders the simulation useless, as the test results will not accurately reflect how a production-grade component would perform.

Ensuring Process Reliability

To achieve a valid simulation of ADI heat treatment, your equipment choice must align with your metallurgical goals.

- If your primary focus is mechanical toughness: Prioritize a furnace with high heat exchange efficiency to prevent early bainite formation during cooling.

- If your primary focus is microstructural consistency: Ensure your equipment offers absolute temperature uniformity to guarantee even carbon enrichment throughout the part.

Precision in the austempering step is not a luxury; it is the prerequisite for high-performance ductile iron.

Summary Table:

| Feature | Salt Bath / Isothermal Furnace | Standard Convection Oven |

|---|---|---|

| Temperature Uniformity | Superior (Liquid medium eliminates cold spots) | Moderate (Prone to air gradients) |

| Heat Exchange Efficiency | High (Rapid cooling to target temp) | Low (Slower heat transfer) |

| Microstructure Control | Precise Ausferrite & Carbon Enrichment | Risk of Brittle Bainite formation |

| Primary Benefit | Consistent mechanical toughness & ductility | Inconsistent material properties |

Elevate Your Metallurgical Precision with KINTEK

Don't let temperature fluctuations compromise your material integrity. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique ADI simulation needs.

Whether you require high heat exchange efficiency to prevent brittle bainite or absolute uniformity for carbon enrichment, our precision equipment ensures your heat treatment results are reliable and scalable.

Ready to achieve superior ausferrite transformation? Contact our experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- P. Lachart, Rainer Masendorf. Prediction of Cross-Section-Dependent ADI Microstructures by Experimental Heat Treatment Simulation. DOI: 10.1007/s40962-023-01246-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does an industrial high-temperature furnace simulate the blast furnace reduction environment? Achieve 30% Reduction

- What processing conditions must a high-temperature homogenization furnace provide? Eliminate Dendritic Segregation

- What methods are used to implement inert atmospheres? Master Purge, Evacuation, and Sealing Techniques

- What are the functions of sample ports and flame curtains in atmospheric furnaces? Ensure Control and Safety in Heat Treatment

- How is a high-temperature resistance furnace used to evaluate TiN coatings? Ensure Reliability for Aerospace Parts

- Why is a reducing atmosphere important? Prevent Oxidation for Superior Material Processing

- What are the two main purposes of furnace atmospheres? Achieve Superior Material Protection and Surface Engineering

- Why is temperature and atmosphere monitoring critical in furnace operations? Ensure Safety and Quality in Heat Treatment