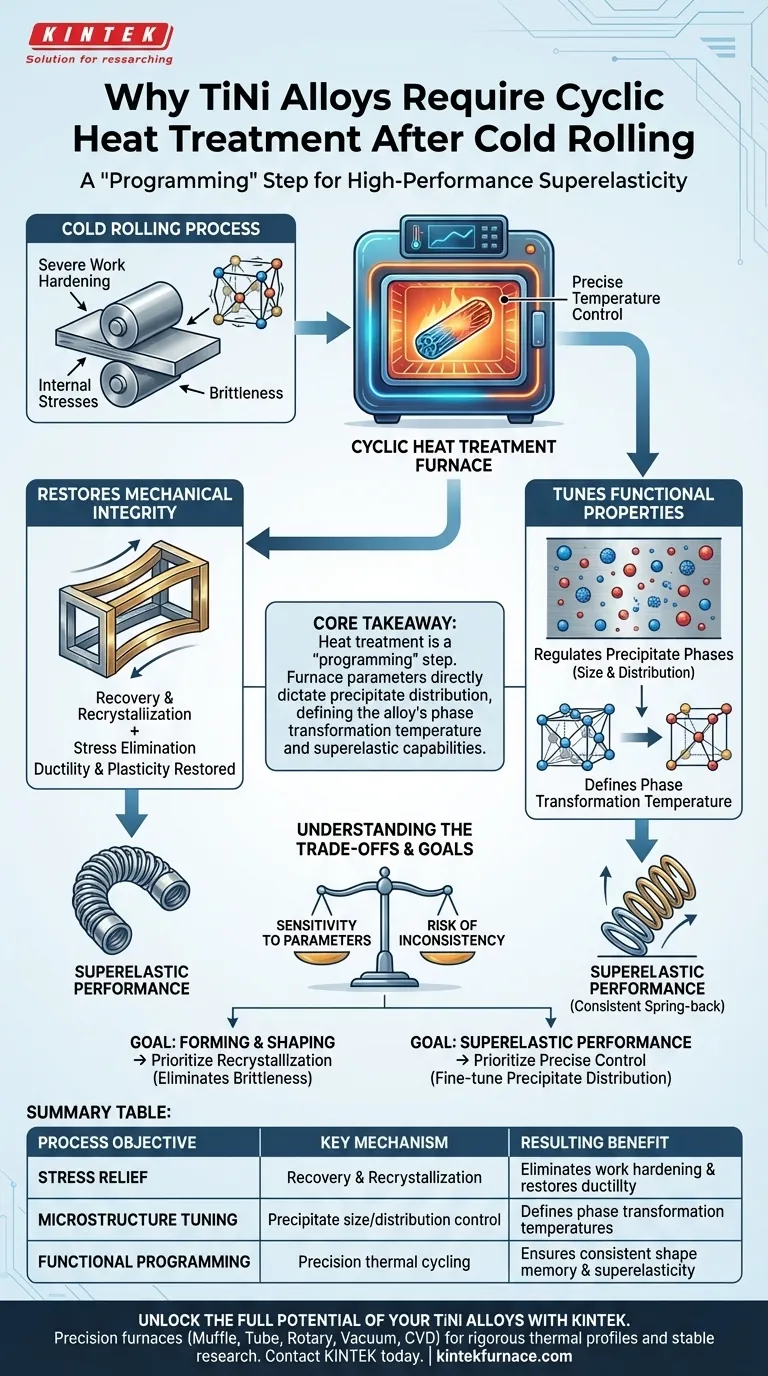

A cyclic heat treatment furnace is required to reverse the severe work hardening and internal stresses that TiNi (Titanium-Nickel) alloys accumulate during cold rolling. This specific equipment provides the precise temperature control necessary to trigger recovery and recrystallization, effectively eliminating stress and restoring the material's plasticity.

Core Takeaway Heat treatment for TiNi alloys is not merely about softening the metal; it is a "programming" step. The furnace parameters directly dictate the size and distribution of precipitates, which defines the alloy's phase transformation temperature and its resulting superelastic capabilities.

The Dual Role of Heat Treatment

Processing TiNi alloys involves more than just shaping the metal; it involves managing its internal microstructure to ensure it functions correctly.

Restoring Mechanical Integrity

Cold rolling significantly alters the physical state of the alloy, leading to work hardening. This process makes the material brittle and introduces high levels of internal residual stress.

The cyclic heat treatment furnace creates the environment needed for recovery and recrystallization. By carefully controlling the heat, the internal structure relaxes, eliminating the residual stress and restoring the ductility (plasticity) needed for further use.

Tuning Functional Properties

TiNi is valued for its functional properties, specifically shape memory and superelasticity. These properties are not inherent to the raw shape but are engineered during heat treatment.

The furnace allows for the precise regulation of temperature and time parameters. These parameters determine the size and distribution of precipitate phases within the alloy's matrix.

Regulating Phase Transformation

The behavior of these precipitates is critical. They directly regulate the phase transformation temperature—the specific point at which the alloy changes from one crystal structure to another.

This structural change is the mechanism behind the alloy's superelastic performance. Without precise control in the furnace, the alloy would not exhibit the consistent spring-back (superelasticity) required for advanced applications.

Understanding the Trade-offs

While the primary goal is restoring plasticity and tuning performance, the process requires a delicate balance.

Sensitivity to Parameters

TiNi alloys are highly sensitive to thermal history. If the temperature or duration in the furnace deviates even slightly, the precipitate distribution changes.

The Risk of Inconsistency

Incorrect parameters can lead to an alloy that is either too soft (loss of functional strength) or one that transforms at the wrong temperature. This renders the superelastic effect useless for its intended operating environment.

Making the Right Choice for Your Goal

The settings you choose within the cyclic heat treatment furnace depend heavily on the final application of the alloy.

- If your primary focus is Forming and Shaping: Prioritize parameters that maximize recrystallization to fully restore plasticity and eliminate brittleness.

- If your primary focus is Superelastic Performance: Prioritize precise control over time and temperature to fine-tune precipitate distribution, ensuring the correct phase transformation temperature.

Summary: The cyclic heat treatment furnace is the bridge between a work-hardened piece of metal and a functional, superelastic component tailored to specific engineering needs.

Summary Table:

| Process Objective | Key Mechanism | Resulting Benefit |

|---|---|---|

| Stress Relief | Recovery & Recrystallization | Eliminates work hardening & restores ductility |

| Microstructure Tuning | Precipitate size/distribution control | Defines phase transformation temperatures |

| Functional Programming | Precision thermal cycling | Ensures consistent shape memory & superelasticity |

Unlock the Full Potential of Your TiNi Alloys with KINTEK

Precision is the difference between a brittle metal and a high-performance superelastic component. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to meet the rigorous thermal profiles required for TiNi processing.

Whether you are focusing on deep recrystallization for forming or fine-tuning precipitate phases for medical-grade superelasticity, our lab high-temp furnaces provide the stability and control your research demands.

Ready to elevate your material science? Contact KINTEK today to find the perfect furnace solution for your unique needs.

Visual Guide

References

- Jiajing Sun. Development of TiNi Alloy Superelastic Guidewire Needle for New Type of Medical Arthroscopic Surgery. DOI: 10.54097/mcmv2h54

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the overall benefits of using vacuum heat treatment furnaces? Achieve Superior Material Purity and Performance

- What is the typical working vacuum degree for most heat treatment vacuum furnaces? Optimize Your Process with the Right Vacuum Level

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What was the traditional insulation setup in vacuum furnaces, and how has it changed? Discover the Modern All-Felt System

- Why are vacuum furnaces important for stainless steel processing? Ensure Corrosion Resistance and Pristine Finishes

- How do vacuum furnaces contribute to energy efficiency and environmental protection? Boost Your Green Manufacturing Today

- What is the mechanism of a high-temperature vacuum furnace in SiC-Al infiltration? Master the Process for Composites

- How is temperature controlled during the heating process in a vacuum furnace? Unlock Precision for High-Integrity Processes