In material processing, the core benefits of a vacuum heat treatment furnace are the complete prevention of surface reactions, an exceptionally clean processing environment, and unparalleled control over temperature. This technology allows for the creation of materials with superior, highly consistent properties that are often impossible to achieve with conventional atmospheric heating methods.

The true value of vacuum heat treatment is not merely avoiding contamination; it is about creating an ultra-pure, stable environment that unlocks superior material properties and process repeatability unattainable with furnaces that operate in air.

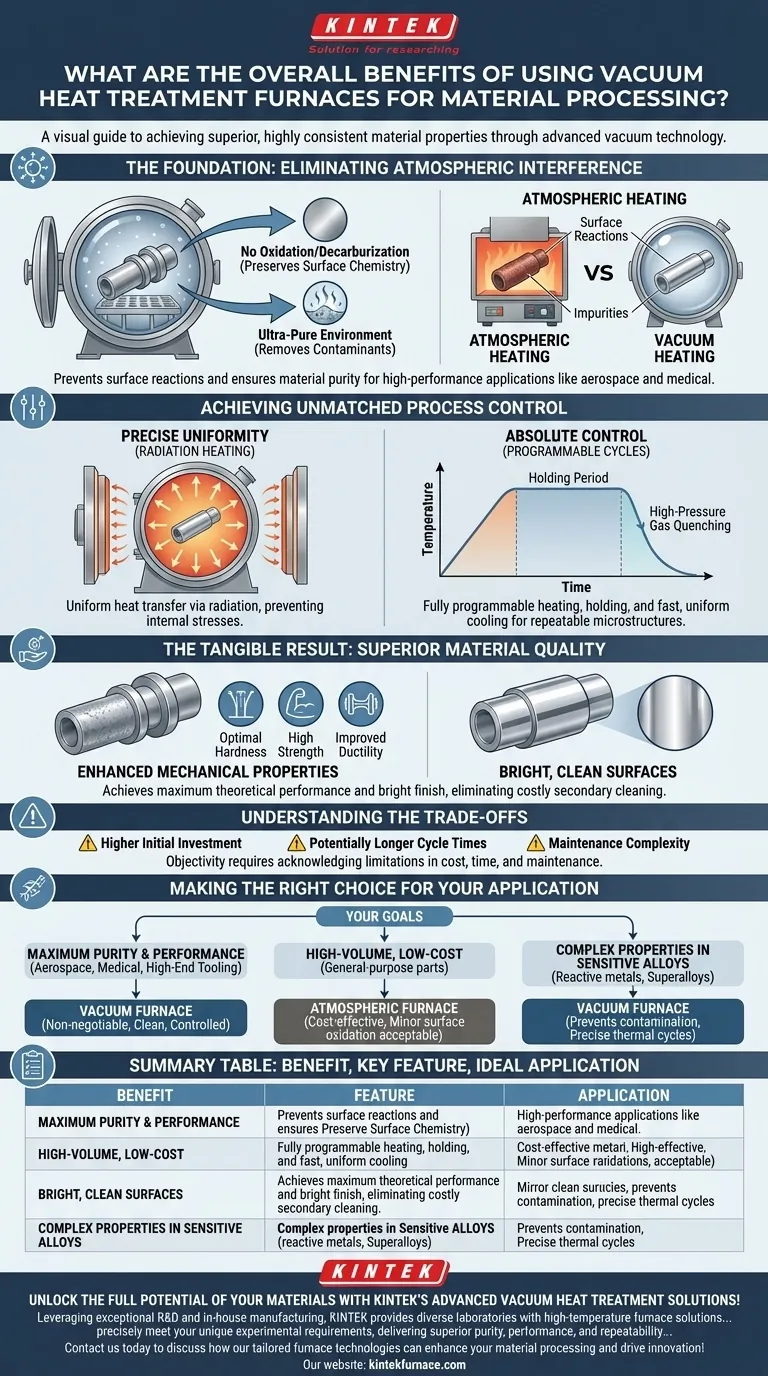

The Foundation: Eliminating Atmospheric Interference

The defining feature of a vacuum furnace is the removal of the atmosphere. This single act solves проблемы inherent to heating materials in the presence of air.

Preventing Oxidation and Decarburization

When metals are heated in air, the oxygen reacts with the surface, forming an oxide layer or scale. This oxidation can alter a part's dimensions and weaken its surface.

Similarly, reactive gases can pull carbon atoms from the surface of steel, a process called decarburization. This softens the steel, compromising its intended hardness and wear resistance. A vacuum environment, by removing these reactive gases, preserves the material's original surface chemistry.

Ensuring Material Purity

A vacuum is the ultimate clean environment. It not only removes reactive gases but also vaporizes and extracts surface contaminants like oils or cleaning fluids early in the heating cycle.

This level of cleanliness is critical for high-performance applications in aerospace, medical, and electronics, where even microscopic impurities can cause a component to fail.

Achieving Unmatched Process Control

Removing the atmosphere fundamentally changes how heat is managed, enabling a level of precision that defines modern material science.

Precise Temperature Uniformity

In a conventional furnace, heat is transferred unevenly by air currents (convection). In a vacuum, heat is transferred primarily through radiation, which is far more uniform.

This ensures the entire workpiece, regardless of its complexity, reaches the target temperature at the same time, preventing internal stresses and inconsistent properties.

Absolute Control Over Heating and Cooling

Vacuum furnaces allow for fully programmable heating and cooling cycles. Operators can precisely manage the ramp-up speed, holding times, and quenching rates.

High-pressure gas quenching, where inert gas is rapidly introduced to cool the part, provides fast, uniform cooling without the distortion risks associated with liquid quenching. This control is key to achieving specific, repeatable microstructures and material properties.

The Tangible Result: Superior Material Quality

The superior environment and control ઓફ a vacuum furnace translate directly into a higher quality final product.

Enhanced Mechanical Properties

By preventing surface flaws and enabling precise thermal cycles, vacuum treatment allows materials to achieve their maximum theoretical performance. This means optimal hardness, strength, and ductility without the compromises of atmospheric processing.

Bright, Clean Surfaces

Parts emerge from a vacuum furnace with a bright, clean, and often shiny finish. Because no oxides form, a vacuum furnace can eliminate the need for costly and time-consuming secondary cleaning processes like sandblasting or acid pickling.

Understanding the Trade-offs

While powerful, vacuum furnace technology is not the universal solution. Objectivity requires acknowledging its limitations.

Higher Initial Investment

Vacuum furnaces and their associated pumping systems represent a significantly higher capital cost compared to conventional atmospheric furnaces.

Potentially Longer Cycle Times

The process of pumping the chamber down to a deep vacuum مستوى can add considerable time to the overall treatment cycle, which can impact throughput for high-volume production.

Maintenance Complexity

Vacuum systems, including pumps, seals, and instrumentation, require specialized knowledge for routine maintenance and troubleshooting, adding to the operational overhead.

Making the Right Choice for Your Application

Selecting the right heat treatment technology depends entirely on your material, your performance requirements, and your production goals.

- If your primary focus is maximum material purity and performance: For mission-critical components in aerospace, medical, or high-end tooling, the clean, controlled environment of a vacuum furnace is non-negotiable.

- If your primary focus is high-volume, low-cost processing: For general-purpose parts where minor surface oxidation is acceptable, a conventional atmospheric furnace is often the more cost-effective choice.

- If your primary focus is achieving complex properties in sensitive alloys: For reactive metals like titanium or advanced superalloys, a vacuum furnace is the only way to prevent contamination and execute the precise thermal cycles required.

Ultimately, investing in a vacuum furnace is a strategic decision to prioritize material integrity and process repeatability above all else.

Summary Table:

| Benefit | Key Feature | Ideal Application |

|---|---|---|

| Prevention of Surface Reactions | Eliminates oxidation and decarburization | Aerospace, Medical, Electronics |

| Clean Processing Environment | Removes contaminants for high purity | Critical components requiring no impurities |

| Precise Temperature Control | Uniform heating via radiation, programmable cycles | Sensitive alloys like titanium and superalloys |

| Enhanced Mechanical Properties | Optimal hardness, strength, and ductility | High-performance tooling and parts |

| Bright, Clean Surfaces | No secondary cleaning needed, cost-saving | Applications where surface finish is critical |

Unlock the full potential of your materials with KINTEK's advanced vacuum heat treatment solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior purity, performance, and repeatability for industries like aerospace and medical.

Contact us today to discuss how our tailored furnace technologies can enhance your material processing and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance