At its core, a vacuum furnace is essential for stainless steel processing because it protects the very properties that make the material "stainless." By removing oxygen and other atmospheric contaminants during high-temperature heat treatment, a vacuum furnace prevents oxidation, discoloration, and decarburization. This ensures the steel retains its corrosion resistance, mechanical strength, and a pristine, bright surface finish without the need for secondary cleaning operations.

The decision to use a vacuum furnace is not just about heat treatment; it is a strategic choice to control the material's chemistry atसेवा level. It guarantees that the final component μαύρη the full, designed-in potential of the stainless steel alloy.

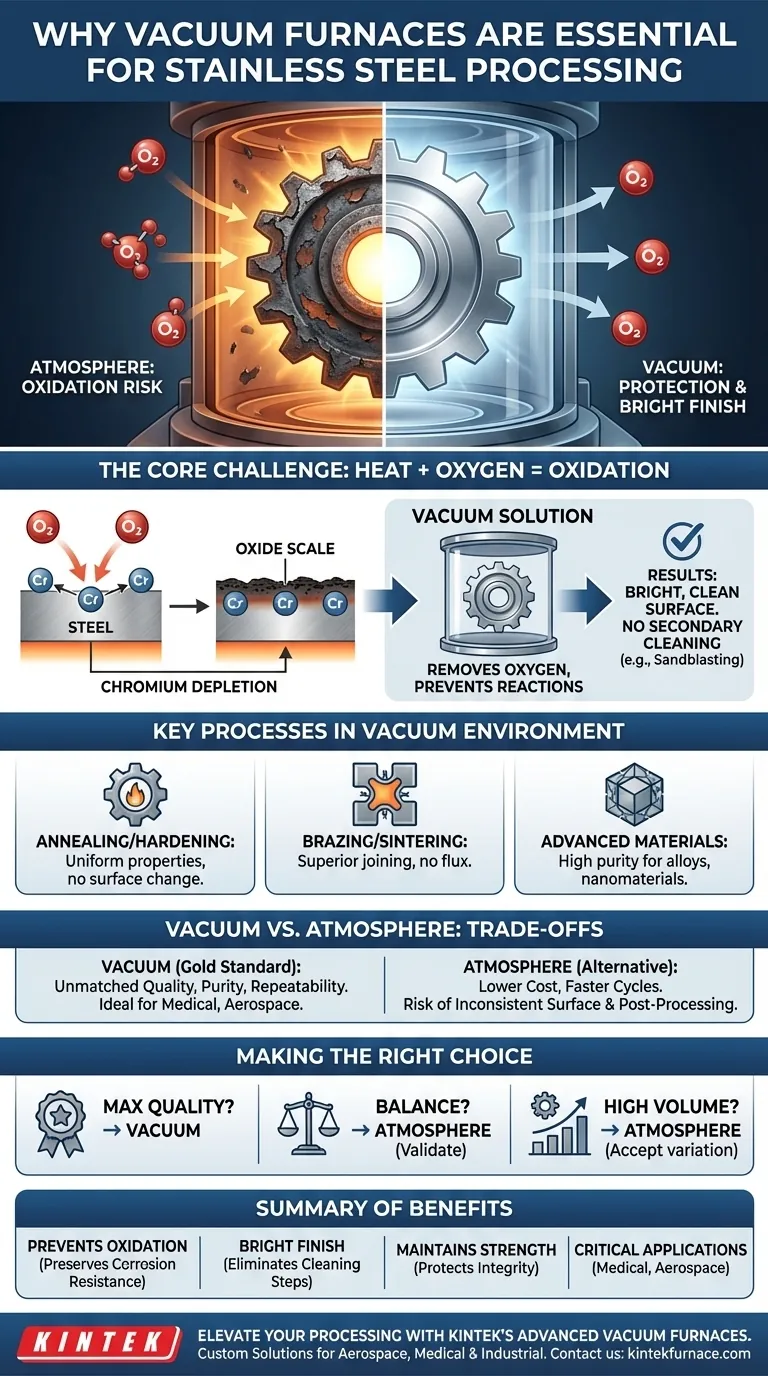

The Core Challenge: Stainless Steel and Oxygen

Why High Temperatures Are a Problem

Stainless steel's defining characteristic is its corrosion resistance, which comes from a high chromium content (typically over 10.5%). This chromium forms a thin, invisible, and passive layer of chromium oxide on the surface that protects the iron from rusting.

However, when you heat stainless steel for processes like annealing, hardening, or brazing, this delicate balance Veränderungen. At high temperatures, the steel becomes highly reactive with any oxygen present in the environment.

The Threat of Oxidation

Without a controlled environment, heating will cause the formation of a thick, dark, and non-protective oxide scale on the surface. This scale ruins the aesthetic finish and, more importantly, can deplete the chromium from the surface layer, compromising the part's corrosion resistance.

A vacuum furnace directly solves this by removing the oxygen, creating an inert environment where these unwanted chemical reactions cannot occur.

The Benefit: A "Bright" Finish

The result of processing in a vacuum is a clean, bright, and scale-free surface. Parts exit the furnace in a finished or near-finished state, often eliminating the need for costly and hazardous post-processing steps like sandblasting or acid pickling to remove scale.

Key Processes That Demand a Vacuum Environment

Annealing and Hardening

For annealing (softening) or through-hardening, the vacuum itself acts as the perfect "atmosphere." It prevents surface reactions, ensuring uniform properties throughout the material without altering the surface chemistry.

Brazing and Sintering

Vacuum brazing is a superior method for joining complex stainless steel assemblies. The vacuum pulls the molten brazing alloy into the tightest joints and eliminates the need for corrosive fluxes, which can become trapped and cause failures later. Similarly, vacuum sintering is used to create dense, strong parts from metal powders.

Advanced Material Processing

The purity of a vacuum environment is critical for developing new materials. It provides an ideal, contamination-free space for the formation of high-purity alloys, superconducting materials, and nanomaterials where even trace impurities can alter the final properties.

Understanding the Trade-offs: Vacuum vs. Atmosphere

While highly effective, vacuum furnaces are not the only option for preventing oxidation. Atmosphere furnaces, which use a protective or "reducing" gas, are another common method.

The Case for Vacuum: Unmatched Quality

A vacuum provides the purest possible environment. It is the gold standard for applications where surface integrity, cleanliness, and process repeatability are non-negotiable. This is especially true for medical, aerospace, and high-purity components.

The Case for Atmosphere: Cost and Throughput

Atmosphere furnaces, which use gases like argon, nitrogen, or hydrogen, can also prevent oxidation effectively. They are often less expensive to purchase and can have faster cycle times than vacuum furnaces, making them suitable for high-volume production of less critical components.

The Hidden Costs of Alternatives

While an atmosphere furnace may have a lower initial cost, it's crucial to evaluate the total cost of production. A seemingly cheaper process can lead to higher expenses from secondary cleaning operations, increased inspection, and higher scrap rates due to inconsistent surface quality.

Making the Right Choice for Your Application

Choosing the correct thermal processing environment is a critical decision that directly impacts part quality, cost, and performance.

- If your primary focus is maximum surface quality, purity, and performance: A vacuum furnace is the unambiguous choice, especially for medical, aerospace, or critical industrial parts.

- If your primary focus is balancing good results with production cost: A high-quality atmosphere furnace with precise gas control can be a viable alternative, but you must validate that it meets your surface finish and cleanliness requirements.

- If your primary focus is high-volume production of less-critical components: An atmosphere furnace is often the more economical and faster solution, provided some surface variation is acceptable.

Ultimately, selecting the right furnace is about preserving the inherent value of the material you are working with.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation | Removes oxygen to avoid scale formation and chromium depletion, preserving corrosion resistance. |

| Ensures Bright Finish | Produces clean, scale-free surfaces, reducing the need for secondary cleaning operations. |

| Maintains Mechanical Strength | Protects material integrity during high-temperature processes like annealing and hardening. |

| Ideal for Critical Applications | Essential for medical, aerospace, and high-purity components where surface quality is non-negotiable. |

Elevate Your Stainless Steel Processing with KINTEK's Advanced Vacuum Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, medical, or industrial sectors, our vacuum furnaces ensure superior corrosion resistance, pristine finishes, and enhanced efficiency for your stainless steel applications.

Contact us today to discuss how we can tailor a solution for your specific needs and unlock the full potential of your materials!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance