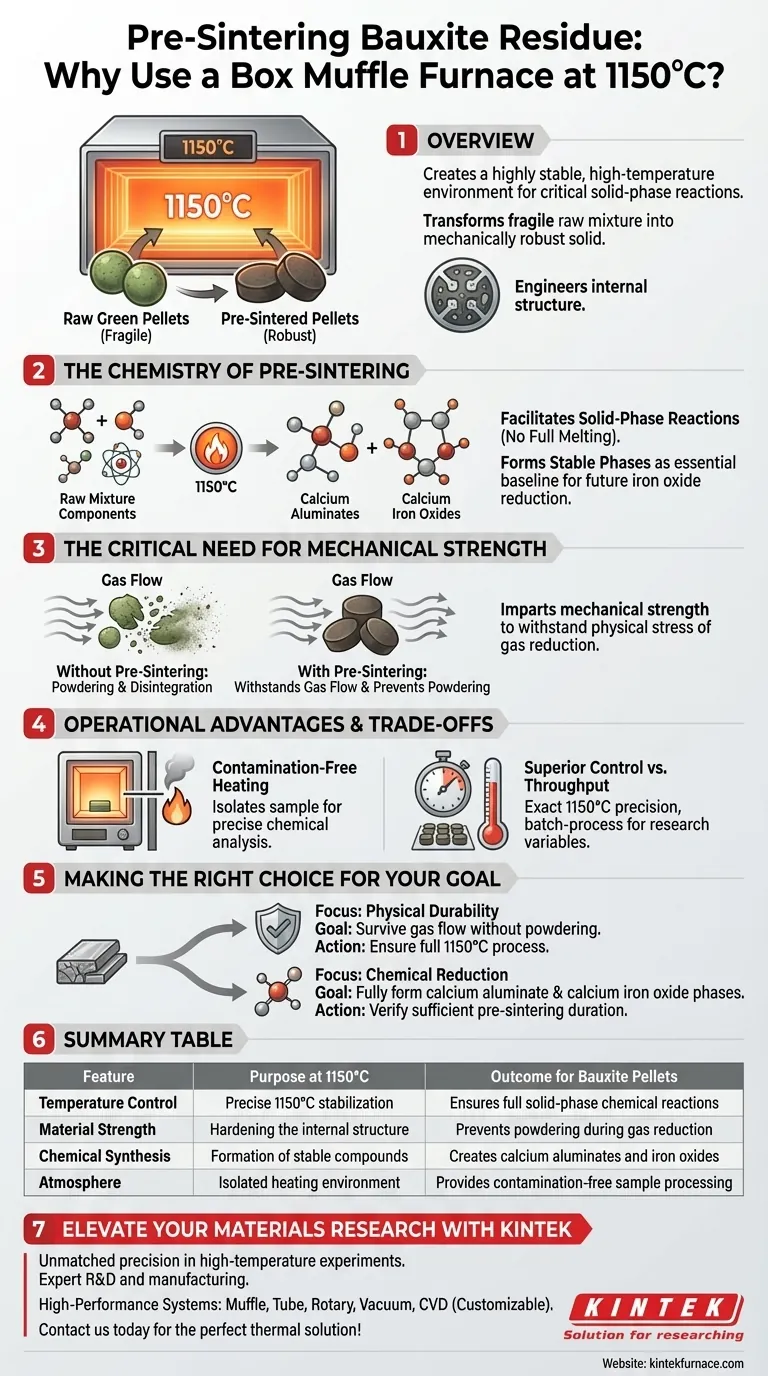

A box muffle furnace is utilized primarily to create a highly stable, high-temperature environment necessary for critical solid-phase reactions. At 1150°C, this apparatus ensures the bauxite residue green pellets undergo specific chemical changes that harden the material, preventing disintegration during later experimental stages.

The core purpose of this process is to engineer the internal structure of the pellet. By pre-sintering in a controlled furnace, you are converting a fragile raw mixture into a mechanically robust solid capable of withstanding the physical stress of gas reduction.

The Chemistry of Pre-Sintering

Facilitating Solid-Phase Reactions

The primary function of the furnace at 1150°C is to drive solid-phase reactions. These are chemical changes that occur within the solid state without the material fully melting.

Creating Stable Phases

Within this thermal environment, the components of the bauxite residue react to form new, stable compounds. Specifically, the process results in the formation of calcium aluminates and calcium iron oxides.

Establishing the Phase Foundation

These new compounds are not arbitrary; they act as the essential baseline for the future. This step establishes the initial phase foundation required for the subsequent iron oxide reduction process.

The Critical Need for Mechanical Strength

Preventing Powdering

The most practical reason for pre-sintering is to impart mechanical strength to the particles. Without this hardening step, the pellets would remain fragile.

Withstanding Gas Flow

Subsequent experiments involve subjecting these pellets to reducing gases. The pre-sintering ensures the pellets are strong enough to withstand the impact of this gas flow without turning into powder (powdering).

Operational Advantages and Trade-offs

Precision and Contamination Control

In laboratory settings, muffle furnaces are favored because they isolate the sample from fuel and combustion byproducts. This allows for contamination-free heating, which is critical when analyzing specific chemical compositions.

Thermal Stability vs. Throughput

These furnaces are equipped with digital controls to maintain the exact 1150°C required for scientific accuracy. However, a common trade-off is that box muffle furnaces are typically batch-process units, meaning they may offer lower throughput compared to continuous industrial kilns, but provide superior control for research variables.

Making the Right Choice for Your Goal

To maximize the effectiveness of your pre-sintering process, consider your specific experimental objectives:

- If your primary focus is Physical Durability: Ensure your process reaches the full 1150°C to guarantee the pellets can survive gas flow without powdering.

- If your primary focus is Chemical Reduction: Verify that the pre-sintering duration is sufficient to fully form the calcium aluminate and calcium iron oxide phases before moving to the reduction stage.

Pre-sintering is the critical bridge that transforms a raw mixture into a viable experimental sample.

Summary Table:

| Feature | Purpose at 1150°C | Outcome for Bauxite Pellets |

|---|---|---|

| Temperature Control | Precise 1150°C stabilization | Ensures full solid-phase chemical reactions |

| Material Strength | Hardening the internal structure | Prevents powdering during gas reduction |

| Chemical Synthesis | Formation of stable compounds | Creates calcium aluminates and iron oxides |

| Atmosphere | Isolated heating environment | Provides contamination-free sample processing |

Elevate Your Materials Research with KINTEK

Ready to achieve unmatched precision in your high-temperature experiments? Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique laboratory needs. Whether you are pre-sintering bauxite residue or developing advanced ceramics, our furnaces provide the thermal stability and contamination control your work demands.

Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Dali Hariswijaya, Jafar Safarian. Studying the Sintering Behavior of H2-Reduced Bauxite Residue Pellets Using High-Temperature Thermal Analysis. DOI: 10.3390/ma18102378

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is a box furnace used for? Achieve Precise Thermal Processing for Your Materials

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What function does a high-temperature muffle furnace serve for Ni/Co catalysts? Transform Salts into Active Metal Oxides

- What is the function of a Muffle Furnace in simulated friction and wear testing? Optimize Your Industrial Tool Coatings

- What materials are used in a box type resistance furnace's structure? Discover the Key Materials for Durability and Efficiency

- Why must ceramic shells undergo high-temperature sintering? Ensure Integrity for High-Melting-Point Alloys

- What are the typical temperature ranges for muffle furnaces and their applications? Optimize Your Lab's Thermal Processes

- What potential hazards are associated with benchtop furnaces? Essential Safety Guide for Lab Users