Operating a benchtop furnace requires a clear understanding of its inherent risks. The primary hazards you must manage are significant: extreme temperatures causing severe burns and fires, high-voltage electrical systems posing shock risks, and the potential release of toxic fumes or harmful gases from the materials being processed. Failing to respect any one of these can lead to serious injury or catastrophic facility damage.

A benchtop furnace concentrates immense energy into a small space. While its power is its purpose, the associated thermal, electrical, and atmospheric hazards are not side effects—they are fundamental operational realities that must be actively managed, not just acknowledged.

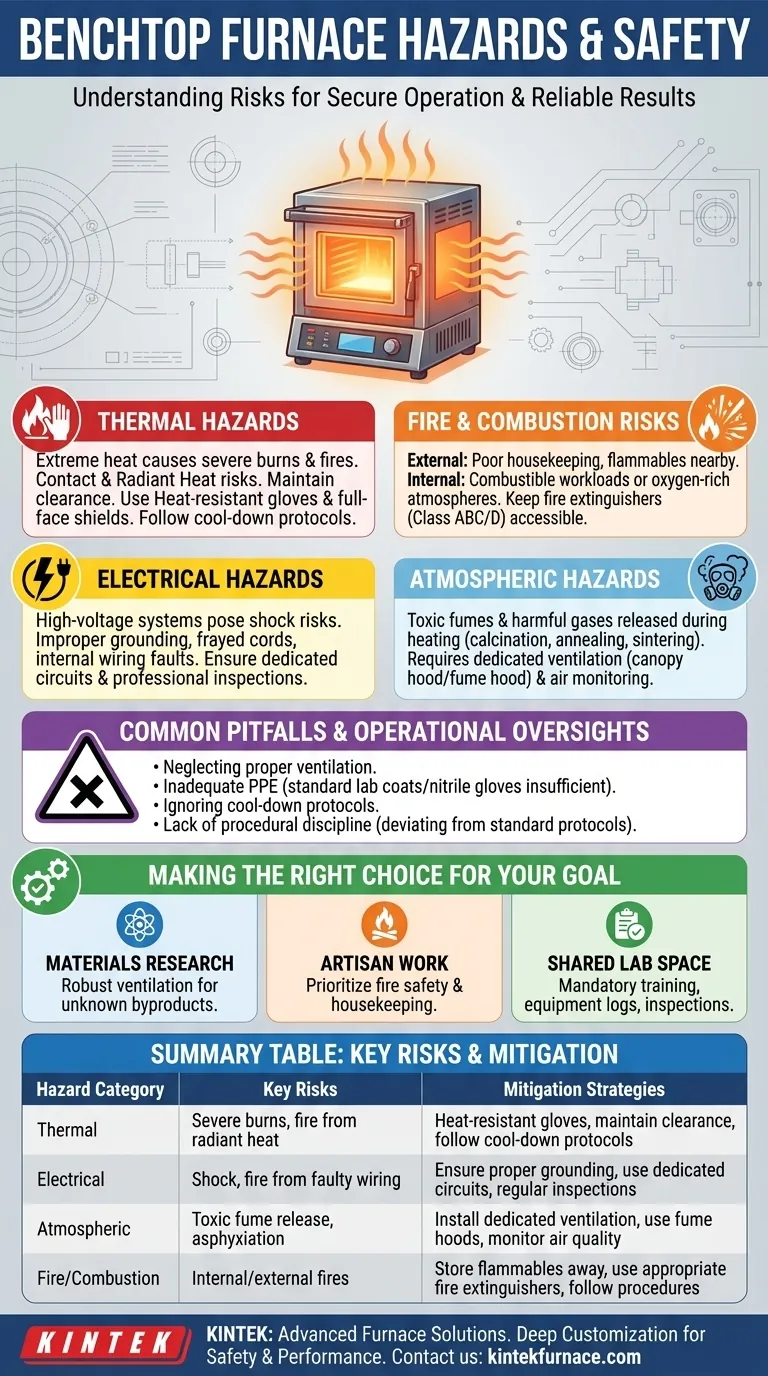

The Primary Hazard Categories

To operate a furnace safely, you must understand the distinct nature of each risk. They often overlap, but each requires specific mitigation strategies.

Thermal Hazards: Beyond the Obvious Burn

The most apparent danger is the extreme heat. The exterior surfaces of a furnace can reach temperatures capable of causing immediate, severe burns even after the unit is turned off.

However, the risk extends beyond direct contact. Radiant heat can damage nearby equipment and, more importantly, poses a fire risk by igniting flammable materials like paper, solvents, or wood that are stored too close to the unit. Always maintain the manufacturer's specified clearance zone.

Fire and Combustion Risks

Fire can originate from external or internal sources. Externally, poor housekeeping and storing flammable materials near the furnace are the most common causes.

Internally, the material being heated (the "workload") can pose a risk. If you are heating materials with combustible binders or processing in an oxygen-rich atmosphere, you risk combustion inside the furnace, which can lead to over-pressurization and catastrophic failure.

Electrical Hazards: Shock and Fire Ignition

Benchtop furnaces are high-power devices, often requiring dedicated, high-amperage circuits. An improperly grounded unit or one with a frayed power cord creates a severe risk of electrical shock.

Furthermore, a fault in the internal wiring or heating elements can serve as an ignition source, potentially starting a fire. All electrical maintenance and inspection should be performed by qualified personnel.

Atmospheric Hazards: What You Can't See

This is often the most overlooked hazard. Heating materials—a process known as calcination, annealing, or sintering—can cause them to release gases or fumes as part of a chemical reaction or as binders burn off.

These emissions can range from irritating to highly toxic or asphyxiating. Without proper and dedicated ventilation, such as a canopy hood ducted to the outside, these gases can accumulate in the workspace, posing a severe health risk to anyone in the area.

Common Pitfalls and Operational Oversights

Most furnace-related incidents are not caused by equipment failure, but by human error. Recognizing these common mistakes is critical for prevention.

Neglecting Proper Ventilation

Assuming a large room provides enough dilution for furnace off-gassing is a dangerous mistake. Many harmful gases are colorless and odorless. The only safe method is to capture fumes at the source with an engineered ventilation system.

Inadequate Personal Protective Equipment (PPE)

Standard lab coats and nitrile gloves offer zero protection from the thermal hazards of a furnace. Proper PPE is non-negotiable and includes:

- Heat-resistant gloves for handling items removed from the furnace.

- Safety glasses at a minimum, with a full-face shield being preferable to protect from radiant heat and potential projectiles.

Ignoring Cool-Down Protocols

A furnace remains a significant thermal hazard long after it has been powered down. Rushing the cool-down process or attempting to remove a workload when it is still too hot can lead to severe burns and thermal shock damage to the material or crucible.

Lack of Procedural Discipline

Every furnace operation should follow a standard procedure, including pre-use inspection, adherence to programmed heating/cooling rates, and proper logging. Deviating from established protocols, especially when leaving a high-temperature process unattended, introduces unnecessary risk.

Making the Right Choice for Your Goal

Your safety strategy should be tailored to your specific application.

- If your primary focus is materials research: Assume your sample will off-gas and ensure your ventilation system is robust enough to handle unknown byproducts.

- If your primary focus is artisan work (e.g., jewelry, enameling): Prioritize fire safety by maintaining rigorous housekeeping and ensuring a Class ABC or Class D fire extinguisher is accessible and you are trained to use it.

- If your primary focus is managing a shared lab space: Implement mandatory user training, a formal equipment logbook, and a schedule for periodic electrical safety inspections by qualified technicians.

A disciplined and safety-conscious approach is the foundation of achieving reliable and repeatable results with any high-temperature equipment.

Summary Table:

| Hazard Category | Key Risks | Mitigation Strategies |

|---|---|---|

| Thermal | Severe burns, fire from radiant heat | Use heat-resistant gloves, maintain clearance, follow cool-down protocols |

| Electrical | Shock, fire from faulty wiring | Ensure proper grounding, use dedicated circuits, regular inspections |

| Atmospheric | Toxic fume release, asphyxiation | Install dedicated ventilation, use fume hoods, monitor air quality |

| Fire/Combustion | Internal/external fires | Store flammables away, use appropriate fire extinguishers, follow procedures |

Ensure your lab's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, minimizing hazards and maximizing performance. Contact us today to discuss how we can support your specific applications and enhance your operational safety!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity