At its core, a box furnace is used for high-temperature thermal processing to fundamentally change the properties of materials. Common applications range from heat-treating metals in industrial manufacturing to synthesizing advanced materials in a research laboratory. These furnaces are essential tools for processes like annealing, sintering, curing, and calcining, where precise temperature control is critical.

A box furnace is not just a high-temperature oven; it is a precision instrument for modifying a material's physical or chemical structure. Its value lies in its ability to create a highly uniform and stable thermal environment, which is essential for achieving specific, repeatable outcomes in both production and research.

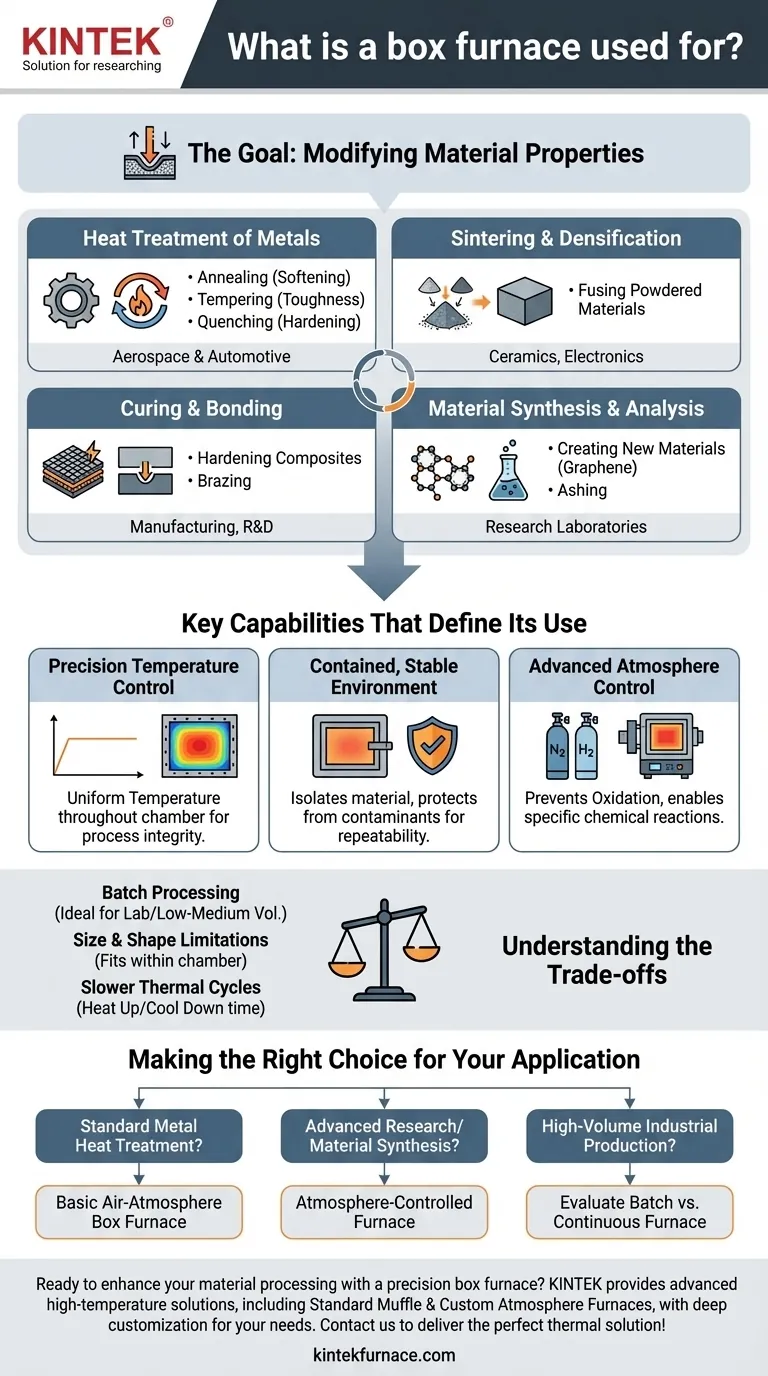

The Goal: Modifying Material Properties

The primary reason to use a box furnace is to subject a material to a controlled thermal cycle. This process is designed to induce specific changes in the material's internal structure, and therefore, its properties.

Heat Treatment of Metals

This is one of the most common industrial applications. Processes like annealing (softening metal), tempering (increasing toughness), and quenching (hardening) all rely on the precise heating and cooling cycles that a box furnace provides.

These treatments are critical in the aerospace and automotive industries for producing strong, durable metal components.

Sintering and Densification

Box furnaces are used to sinter powdered materials, such as ceramics or metals. In this process, the material is heated to a high temperature, just below its melting point, causing the particles to fuse together into a solid, dense object.

This is how many advanced ceramic parts, from dental implants to electronic components, are created.

Curing and Bonding

For composites, adhesives, and coatings, a furnace is used for curing. The heat initiates a chemical reaction that hardens the material, giving it the desired strength and stability.

Similar processes, like brazing, use a furnace to melt a filler metal to join two or more components together.

Material Synthesis and Analysis

In research and development, box furnaces are used to create entirely new materials. By heating elements in a controlled environment, scientists can synthesize materials like graphene or metal nanoparticles.

They are also used for laboratory analysis, such as determining the elemental composition of a sample (ashing) or preparing it for further testing.

Key Capabilities That Define Its Use

A box furnace is chosen over other heating methods because of a few key features that ensure process integrity and repeatability.

Precision Temperature Control

Modern box furnaces have advanced control systems that maintain a highly uniform temperature throughout the chamber. This precision is non-negotiable for sensitive processes where even a few degrees of deviation can compromise the final product.

Contained, Stable Environment

The enclosed chamber of a box furnace isolates the material from the outside environment. This protects the part from contaminants and ensures a stable, consistent heating process, which is vital for achieving repeatable results.

Advanced Atmosphere Control (Specialized Models)

Standard furnaces operate with an air atmosphere. However, atmosphere box furnaces allow you to replace the air with a specific gas, such as nitrogen (inert) or hydrogen (reducing).

This control is critical for preventing oxidation on sensitive metals or enabling specific chemical reactions needed for advanced material synthesis.

Understanding the Trade-offs

While incredibly versatile, the box furnace design has inherent limitations that make it unsuitable for certain applications.

Batch Processing, Not Continuous

A box furnace operates on a batch basis. You load the material, run the heating cycle, cool it down, and then unload it. This is highly effective for labs or low-to-medium volume production.

For high-volume manufacturing, a continuous or "tunnel" furnace, where parts move through on a conveyor, is often a more efficient solution.

Physical Size and Shape Limitations

The "box" design is best suited for parts that can fit comfortably within its chamber. It is not practical for processing exceptionally large components or parts with extremely long, awkward geometries.

Thermal Cycles Can Be Slow

Because they are well-insulated to maintain temperature uniformity, box furnaces can take a significant amount of time to heat up and cool down. This "thermal mass" can impact overall throughput when many batches need to be processed quickly.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your end goal.

- If your primary focus is standard metal heat treatment: A basic air-atmosphere box furnace with reliable temperature control will meet your needs for processes like annealing or tempering.

- If your primary focus is advanced research or material synthesis: You must prioritize an atmosphere-controlled furnace to prevent oxidation and enable specific chemical reactions.

- If your primary focus is high-volume industrial production: You should evaluate if the batch-based nature of a box furnace fits your throughput needs, or if a continuous furnace system is more appropriate.

Understanding these core functions and trade-offs ensures you select the right tool to achieve your material processing goals.

Summary Table:

| Application | Primary Goal | Key Industries |

|---|---|---|

| Heat Treatment | Annealing, Tempering, Hardening | Aerospace, Automotive |

| Sintering | Densifying Powdered Materials | Ceramics, Electronics |

| Curing & Bonding | Hardening Composites, Adhesives | Manufacturing, R&D |

| Material Synthesis | Creating New Materials (e.g., Graphene) | Research Laboratories |

Ready to enhance your material processing with a precision box furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Whether you need a standard Muffle Furnace for heat treatment or a custom Atmosphere Furnace for sensitive material synthesis, our diverse product line and strong deep customization capabilities are designed to meet your unique experimental and production requirements. Contact us today to discuss how we can deliver the perfect thermal solution for your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does the airflow and temperature distribution differ between drying ovens and muffle furnaces? Key Insights for Lab Efficiency

- What is a box furnace and what are its main characteristics? Discover Versatile Batch Heating Solutions

- Why is a high-temperature blackbody furnace required for calibration? Ensure Precision in Tuyere Flame Measurement

- What critical testing environment does a high-temperature muffle furnace provide for resin burn-off analysis?

- Why is heating rate control critical for AA7050 alloy treatment? Master Microstructural Evolution in Lab Furnaces

- What are the key characteristics of box type electric furnaces? Precision Heating for Labs and Industry

- How is a Muffle furnace used in environmental treatment? Essential for Waste Analysis and Small-Scale Incineration

- What role does a muffle furnace play in the synthesis of g-C3N4/TiO2? Essential Thermal Processing for Composites