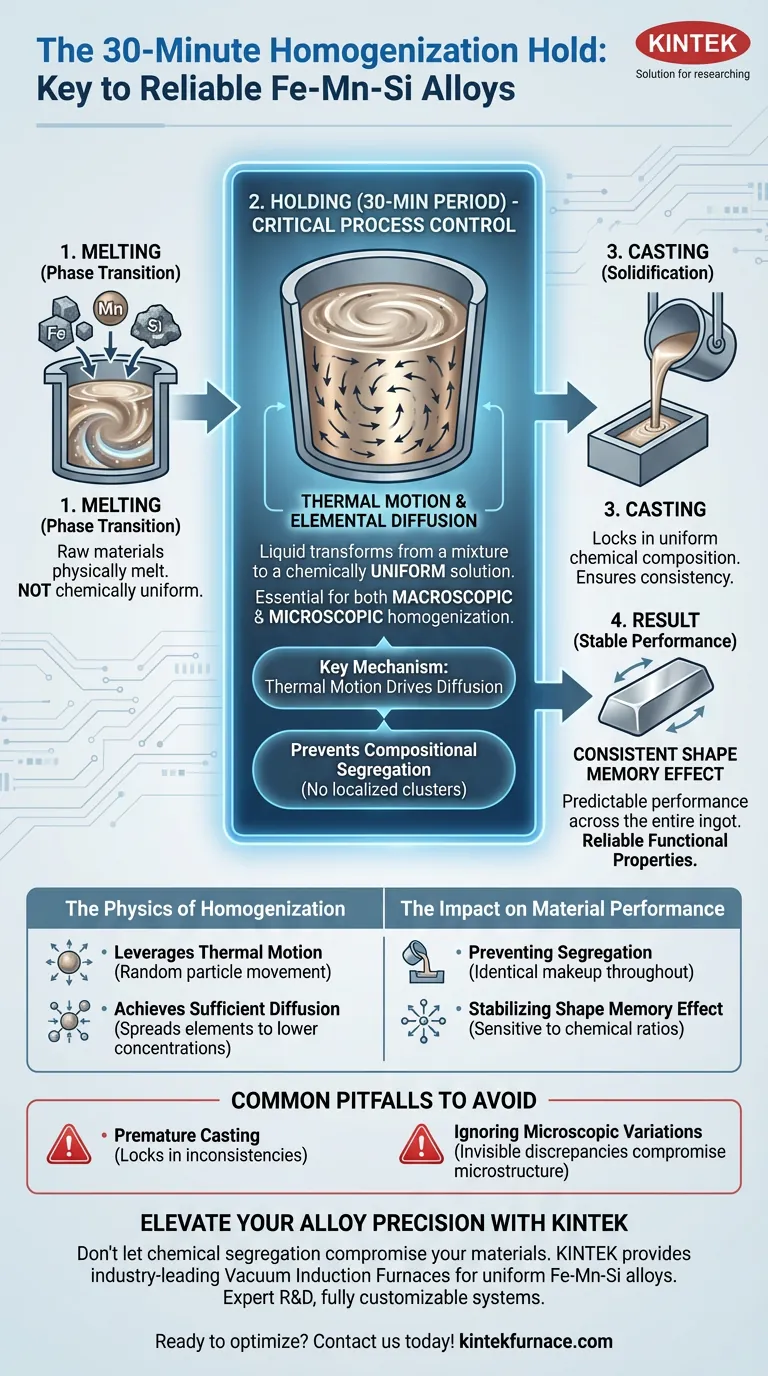

The 30-minute holding period is a critical process control for chemical homogenization. Once the raw materials for Fe-Mn-Si alloys have physically melted, this specific duration allows thermal motion to drive the necessary diffusion of elements throughout the crucible. Simply melting the metal is not enough; this dwell time ensures the liquid transforms from a mixture of ingredients into a chemically uniform solution before it is cast.

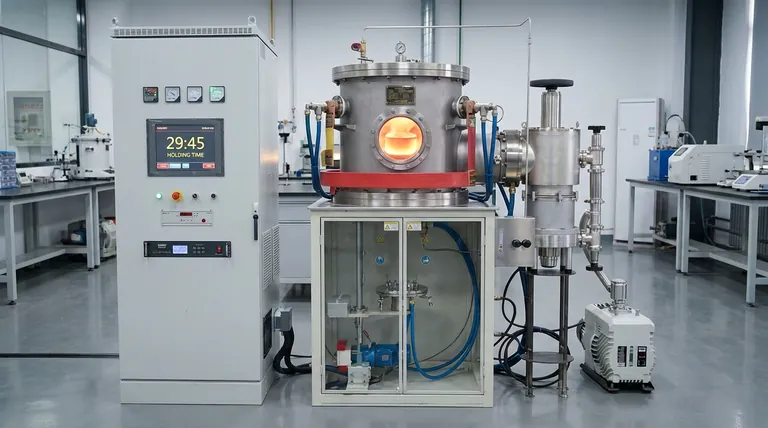

By maintaining the melt in a vacuum induction furnace for 30 minutes, you allow sufficient time for elemental diffusion to occur. This ensures a consistent composition on both macroscopic and microscopic scales, which is the foundational requirement for stable shape memory effect performance.

The Physics of Homogenization

Leveraging Thermal Motion

Melting is a physical phase change, but it does not guarantee immediate chemical uniformity. Even after the raw materials turn to liquid, the heavy elements and lighter elements may not be evenly distributed.

The 30-minute hold utilizes thermal motion—the random movement of particles driven by heat—to naturally mix the alloy. This period allows the kinetics of the liquid to stabilize.

Achieving Sufficient Diffusion

Diffusion is the mechanism by which high concentrations of specific elements spread out into areas of lower concentration. In Fe-Mn-Si alloys, ensuring that Manganese and Silicon are perfectly intermixed with the Iron matrix is vital.

Without this specific window of time, the diffusion process remains incomplete. The resulting ingot would contain localized areas rich or poor in specific alloying elements.

The Impact on Material Performance

Preventing Compositional Segregation

The primary adversary in casting complex alloys is segregation. This occurs when chemical components separate or cluster rather than remaining in a solid solution.

A holding period acts as a countermeasure to segregation. It ensures that the chemical makeup of the melt is identical at the bottom, middle, and top of the crucible before the pour begins.

Stabilizing the Shape Memory Effect

Fe-Mn-Si alloys are prized for their shape memory effect, a functional property that is highly sensitive to chemical ratios.

If the composition fluctuates on a microscopic or macroscopic scale, the material's ability to return to its original shape will vary unpredictably across the ingot. Homogeneity ensures that every section of the cast metal performs consistently under stress.

Common Pitfalls to Avoid

The Risk of Premature Casting

A common error in vacuum induction melting is assuming that "liquid" equals "ready." Casting immediately after the charge melts is a critical mistake.

Rushing this step locks in chemical inconsistencies. Once the metal solidifies in the mold, any segregation present in the melt becomes permanent, leading to a high rejection rate for the final components due to unreliable performance.

Ignoring Microscopic Variations

It is possible for an alloy to appear mixed to the naked eye while still suffering from microscopic segregation.

The 30-minute standard is specifically designed to address these invisible discrepancies. It provides the necessary soak time to resolve compositional gradients that could otherwise compromise the microstructure of the finished alloy.

Making the Right Choice for Your Goal

To maximize the quality of your Fe-Mn-Si alloy castings, adhere to the following guidelines:

- If your primary focus is Reliability: Strictly enforce the 30-minute holding time to guarantee that compositional segregation is eliminated prior to casting.

- If your primary focus is Functional Performance: Prioritize melt homogeneity to ensure the shape memory effect is consistent throughout the entire ingot.

Uniform chemistry is the absolute prerequisite for predictable physical behavior in functional alloys.

Summary Table:

| Process Phase | Primary Mechanism | Core Objective |

|---|---|---|

| Melting | Phase Transition | Solid to liquid conversion |

| Holding (30 min) | Thermal Diffusion | Macroscopic & microscopic homogenization |

| Casting | Solidification | Locking in uniform chemical composition |

| Result | Shape Memory Stability | Consistent material performance across the ingot |

Elevate Your Alloy Precision with KINTEK

Don't let chemical segregation compromise your materials. KINTEK provides industry-leading Vacuum Induction Furnaces designed for the rigorous demands of functional alloy production. Backed by expert R&D and manufacturing, we offer fully customizable Muffle, Tube, Rotary, Vacuum, and CVD systems to ensure your Fe-Mn-Si alloys achieve perfect homogeneity and reliable shape memory effects every time.

Ready to optimize your high-temperature processes? Contact us today for a custom solution!

Visual Guide

References

- Haojie Niu, Chengxin Lin. Study on the Effect of Solid Solution Treatment on the Bending Fatigue Property of Fe-Mn-Si Shape Memory Alloys. DOI: 10.3390/met14040441

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do induction furnaces generate heat for smelting precious metals? Discover Fast, Pure Melting Solutions

- What are the advantages of using a vacuum induction melting furnace? Achieve Unmatched Purity and Control

- What is the role of a Vacuum Induction Melting Furnace? Essential Purity for Amorphous Nanocrystalline Materials

- What role does a vacuum induction melting furnace play in the K439B superalloy? Ensure High-Purity Casting Outcomes

- What are the cost implications of using electric crucible furnaces? Uncover the True Total Cost of Ownership

- How is brazing performed using induction heating? Achieve Fast, Precise Metal Joining

- What is the role of frequency in melting PGM powders in an induction furnace? Essential for efficient heating and melting.

- What is Joule heating and how does it relate to induction furnaces? Master Efficient Metal Melting