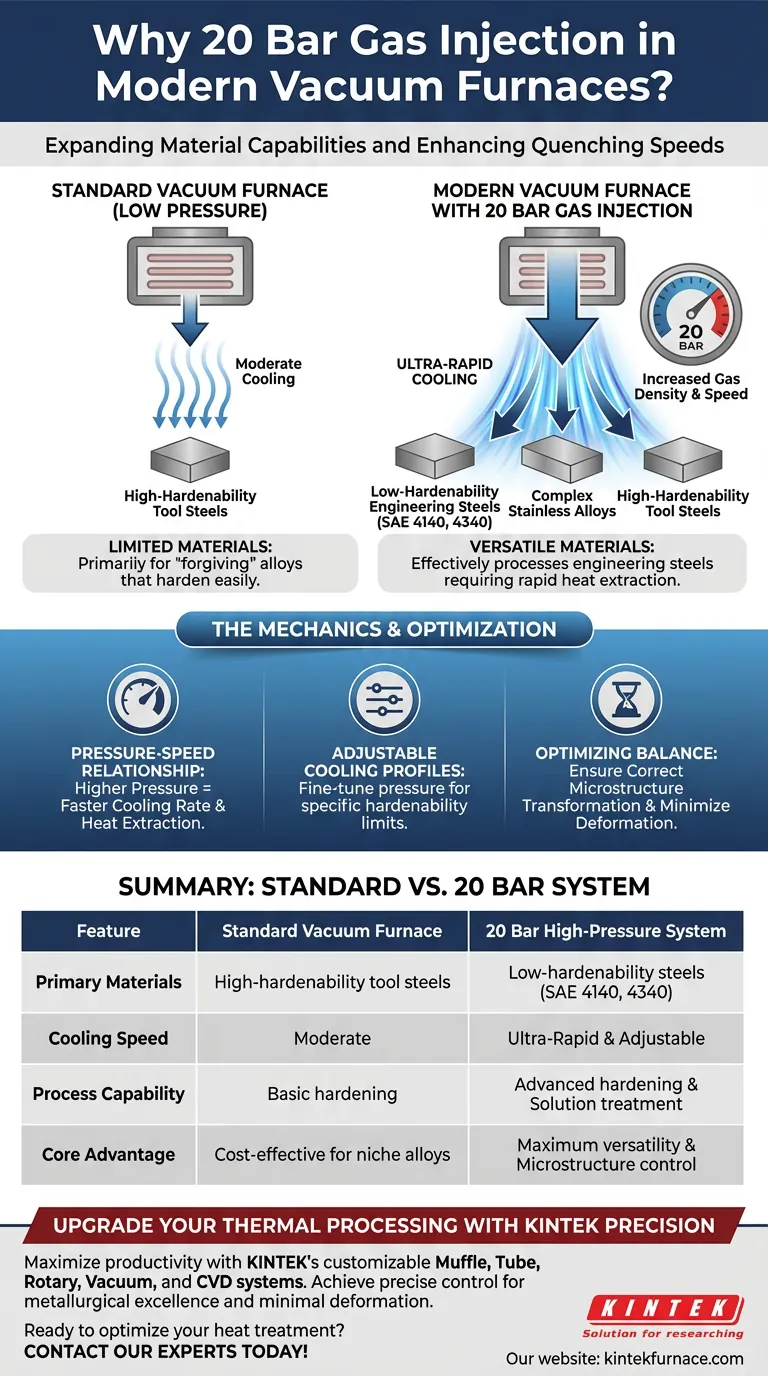

Modern vacuum furnaces utilize 20 bar gas injection systems to significantly increase quenching speeds, thereby expanding the range of treatable materials. While standard vacuum furnaces handle high-hardenability tool steels easily, the increased pressure allows for the effective processing of low-hardenability engineering steels and complex stainless alloys.

By increasing gas injection pressure to 20 bar, operators can drastically accelerate cooling rates. This transforms the vacuum furnace from a niche tool for high-grade alloys into a versatile system capable of hardening common engineering steels like SAE 4140 and 4340.

Expanding Material Capabilities

Moving Beyond Tool Steels

Historically, vacuum furnaces were primarily restricted to high-hardenability tool steels. These materials are "forgiving," meaning they can harden properly even with slower cooling rates.

Processing Engineering Steels

The introduction of 20 bar systems opens the door to low-hardenability engineering steels, such as SAE 4140 and 4340. These materials require rapid heat extraction to achieve the desired hardness. Without high-pressure quenching, these steels would not transform correctly in a vacuum environment.

Solution Treatment for Stainless Alloys

High-pressure capabilities are also essential for the solution treatment of special stainless steels. These alloys often require specific, rapid cooling profiles to maintain corrosion resistance and mechanical strength.

The Mechanics of High-Pressure Quenching

The Pressure-Speed Relationship

There is a direct correlation between gas injection pressure and the quenching rate. As pressure increases to 20 bar, the density of the cooling gas increases, allowing it to extract heat from the workload much faster.

Adjustable Cooling Profiles

A 20 bar system does not force you to always run at maximum pressure. Instead, it provides a higher "ceiling" for performance. Technicians can adjust the pressure to match the specific hardenability limits of the material being treated.

Optimizing the Cooling Balance

Ensuring Microstructure Transformation

The primary goal of the increased pressure is to ensure the steel undergoes the correct microstructural transformation. If the cooling is too slow, the material will not harden; it will remain soft and structurally weak.

Controlling Deformation

While speed is necessary for hardness, uncontrolled rapid cooling can cause warping or cracking. The advantage of a modern 20 bar system is the ability to fine-tune the cooling rate. This allows the operator to cool the part just fast enough to harden it, but slow enough to minimize deformation.

Making the Right Choice for Your Goal

To determine if a 20 bar system is necessary for your operations, consider your specific metallurgical requirements.

- If your primary focus is Operational Versatility: A 20 bar system is essential if you plan to process a mix of high-grade tool steels and common engineering steels like SAE 4140.

- If your primary focus is Dimensional Precision: The adjustable pressure allows you to find the perfect equilibrium between achieving hardness and maintaining the part's shape.

Ultimately, a 20 bar gas injection system offers the critical flexibility needed to treat a wider spectrum of alloys without compromising on metallurgical quality.

Summary Table:

| Feature | Standard Vacuum Furnace | 20 Bar High-Pressure System |

|---|---|---|

| Primary Materials | High-hardenability tool steels | Low-hardenability steels (SAE 4140, 4340) |

| Cooling Speed | Moderate | Ultra-Rapid & Adjustable |

| Process Capability | Basic hardening | Advanced hardening & Solution treatment |

| Core Advantage | Cost-effective for niche alloys | Maximum versatility & Microstructure control |

Upgrade Your Thermal Processing with KINTEK Precision

Maximize your lab's productivity and material versatility with KINTEK’s high-performance vacuum systems. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific high-temperature requirements. Whether you are quenching engineering steels at 20 bar or performing delicate solution treatments, our furnaces deliver the precise control you need to ensure metallurgical excellence and minimal deformation.

Ready to optimize your heat treatment results? Contact our experts today to find your custom solution!

Visual Guide

References

- André Paulo Tschiptschin. PROCESSOS SOB VÁCUO USADOS PARA TRATAMENTOS TÉRMICOS E DE SUPERFÍCIE DE AÇOS E LIGAS ESPECIAIS. DOI: 10.17563/rbav.v43i1.1262

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the function of the condenser within a vacuum distillation furnace used for magnesium recycling? Achieve High-Purity Magnesium Recovery

- What is the function of the heating chamber in a drop-bottom quench furnace? Ensure Precise Heat Treatment for Superior Metallurgy

- What is the maximum temperature a vacuum furnace can reach? Up to 2600°C for Advanced Materials Processing

- What is the purpose of utilizing a high vacuum system and vacuum sealing? Ensure Purity in Alloy Synthesis

- How does the atmosphere in a high vacuum sintering furnace affect 17-4PH properties? Optimize Density and Hardness

- What applications does a vacuum melting furnace have in research? Unlock High-Purity Material Development

- What is the function of a heating furnace in the distillation separation process of a High Vacuum Unit (HVU)?

- What are the key components of a vacuum sintering furnace? Essential Parts for Precision Material Processing