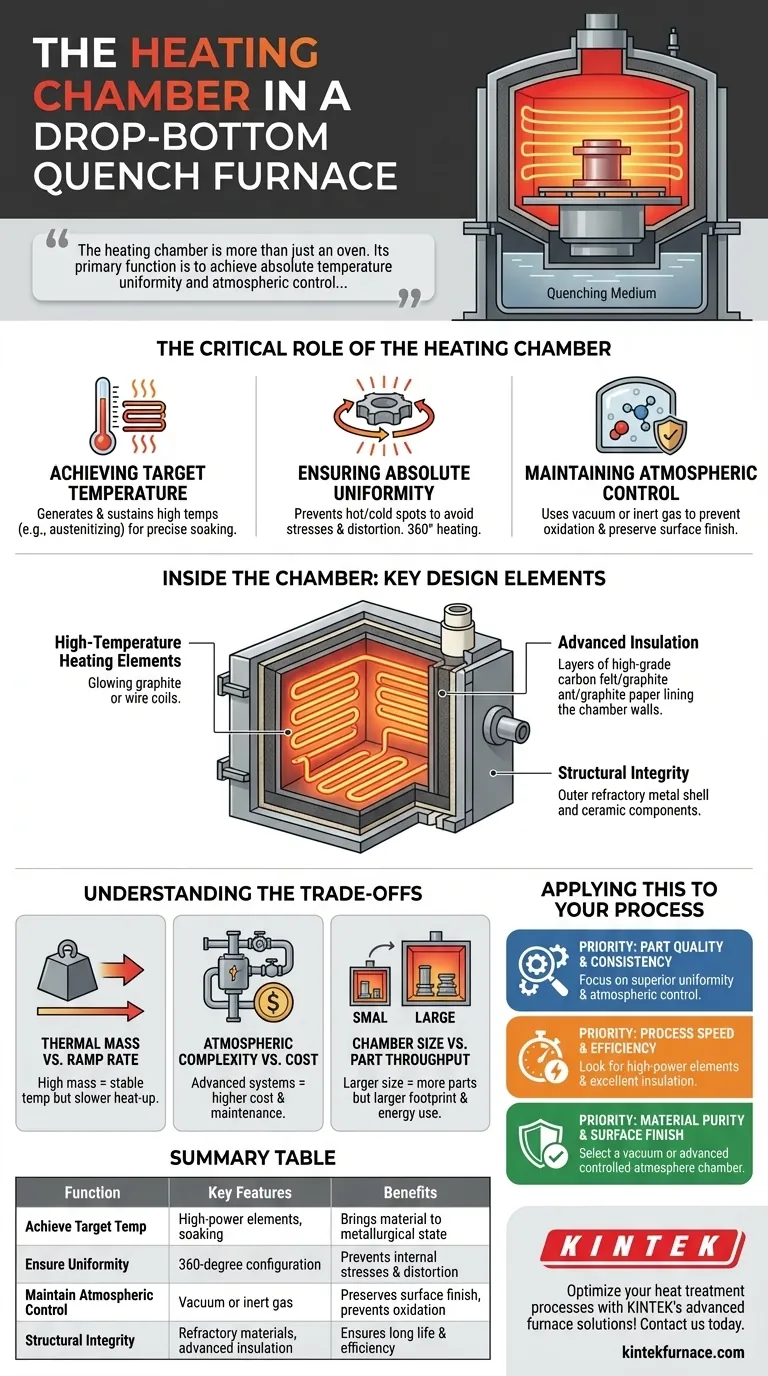

At its core, the heating chamber is the insulated section of a drop-bottom quench furnace where materials are heated to precise, high temperatures. Its essential function is to bring a component to its required metallurgical state through controlled heating before it is rapidly dropped into the quenching medium below.

The heating chamber is more than just an oven. Its primary function is to achieve absolute temperature uniformity and atmospheric control, ensuring every part of the component is perfectly prepared for the critical, rapid transfer into the quench tank.

The Critical Role of the Heating Chamber

The heating chamber is the heart of the heat treatment process. Its design and operation directly determine the final properties of the material being treated.

Achieving Target Temperature

The most fundamental function of the chamber is to generate and sustain the high temperatures required for heat treatment. This is accomplished using powerful, strategically placed heating elements.

The goal is to bring the material to a specific temperature, such as its austenitizing temperature for steels, and hold it there for a precise duration (the "soaking" phase).

Ensuring Absolute Uniformity

For successful heat treatment, the entire component must reach the target temperature evenly. Any hot or cold spots can lead to internal stresses, distortion, or inconsistent material properties.

To prevent this, heating elements and sometimes gas nozzles are often distributed uniformly in a 360-degree configuration around the part, guaranteeing consistent and homogenous heating.

Maintaining Atmospheric Control

Many modern heating chambers are designed to control the atmosphere surrounding the part. This prevents undesirable chemical reactions, such as oxidation (scaling), that can occur at high temperatures.

By using a vacuum or introducing a controlled, inert gas, the chamber isolates the component from oxygen and other contaminants, preserving its surface finish and metallurgical purity.

Inside the Chamber: Key Design Elements

The chamber's ability to perform its function depends on several critical components working in concert.

High-Temperature Heating Elements

These are the core components that generate the heat. Depending on the furnace's design and temperature range, these can be made of materials like graphite tubes or specialized resistance-wire alloys.

Advanced Insulation

To maintain extreme temperatures efficiently and protect the furnace's external structure, the chamber is lined with high-performance insulation.

Materials like high-grade carbon felt, flexible graphite paper, or refractory ceramics are used to minimize heat loss, ensuring temperature stability and operational efficiency.

Structural Integrity

The chamber itself must be constructed from materials that can withstand repeated cycles of extreme heat without degrading. Refractory metals and ceramics are often used to ensure a long operational life and maintain a clean internal environment.

Understanding the Trade-offs

While essential, the design of a heating chamber involves balancing competing factors.

Thermal Mass vs. Ramp Rate

A chamber with thick, heavy insulation (high thermal mass) will be very energy-efficient at holding a stable temperature. However, it may take longer to heat up to the target temperature (a slower "ramp rate").

Atmospheric Complexity vs. Cost

Implementing vacuum or controlled atmosphere systems adds significant complexity and cost to both the initial purchase and ongoing maintenance of the furnace. This feature is a trade-off between the need for material purity and operational budget.

Chamber Size vs. Part Throughput

The internal volume of the heating chamber directly limits the size and number of parts that can be processed in a single batch. Larger chambers increase throughput but also consume more energy and require a larger footprint.

Applying This to Your Process

Your specific heat-treating goal will determine which aspects of the heating chamber are most important for your application.

- If your primary focus is part quality and consistency: Prioritize a chamber design that guarantees superior temperature uniformity and precise atmospheric control.

- If your primary focus is process speed and efficiency: Look for a chamber with high-power heating elements for fast ramp-up times and excellent insulation to reduce energy loss during soaking.

- If your primary focus is material purity and surface finish: Select a furnace with a vacuum or advanced controlled-atmosphere chamber to prevent any oxidation or contamination during heating.

Ultimately, the heating chamber's design directly dictates the quality, consistency, and final properties of your heat-treated components.

Summary Table:

| Function | Key Features | Benefits |

|---|---|---|

| Achieve Target Temperature | High-power heating elements, soaking phase | Brings material to required metallurgical state |

| Ensure Uniformity | 360-degree heating element configuration | Prevents internal stresses and distortion |

| Maintain Atmospheric Control | Vacuum or inert gas systems | Preserves surface finish and prevents oxidation |

| Structural Integrity | Refractory materials, advanced insulation | Ensures long operational life and efficiency |

Optimize your heat treatment processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing quality, consistency, and efficiency. Contact us today to discuss how we can support your metallurgical goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production