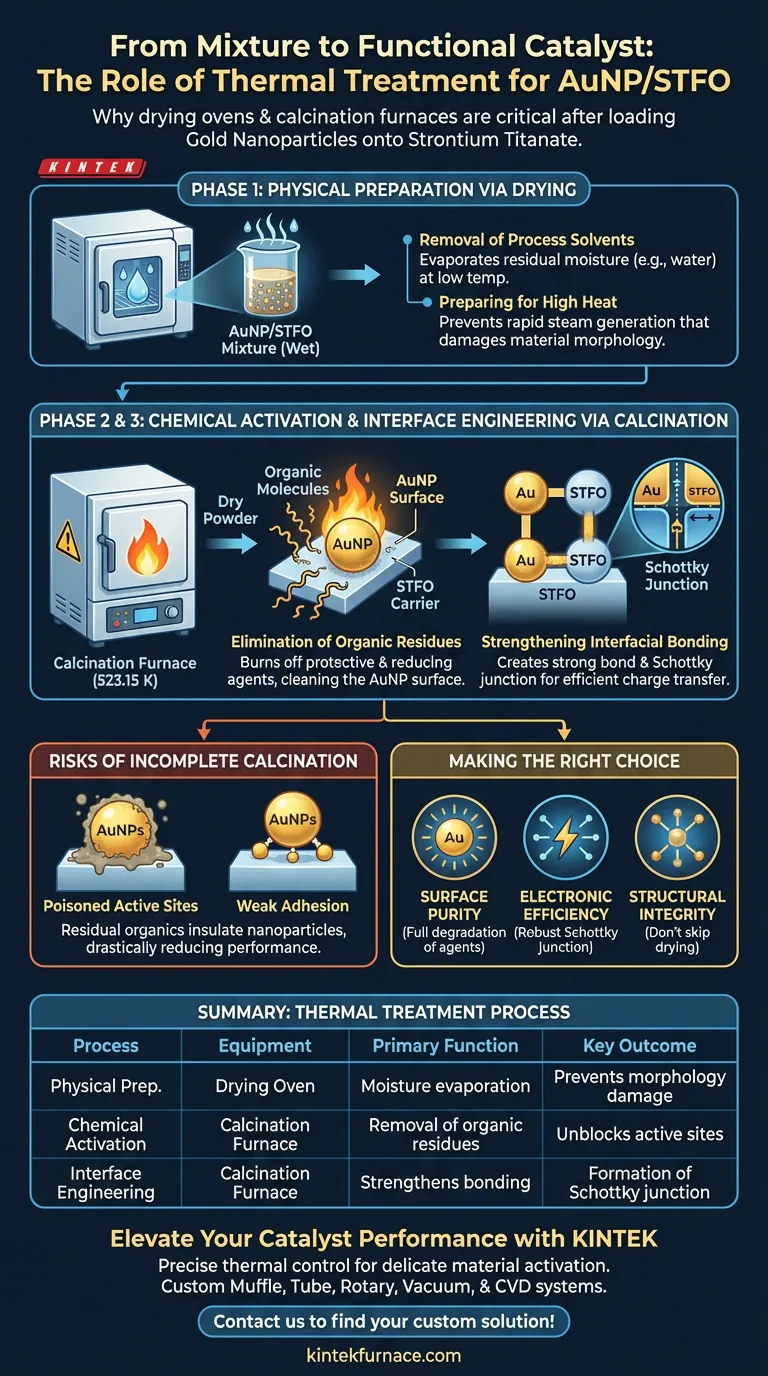

The post-loading thermal treatment is the decisive step that transitions your material from a simple mixture to a functional catalyst. The drying oven is required to evaporate residual moisture remaining from the initial washing process, ensuring the sample is physically dry. The calcination furnace then performs the critical chemical activation, stripping away organic contaminants and structurally bonding the gold nanoparticles (AuNPs) to the Strontium Titanate (STFO) carrier.

While drying ensures the physical readiness of the sample, calcination drives the chemical changes required for performance. It transforms a loosely associated mixture into a unified composite with efficient charge transfer capabilities.

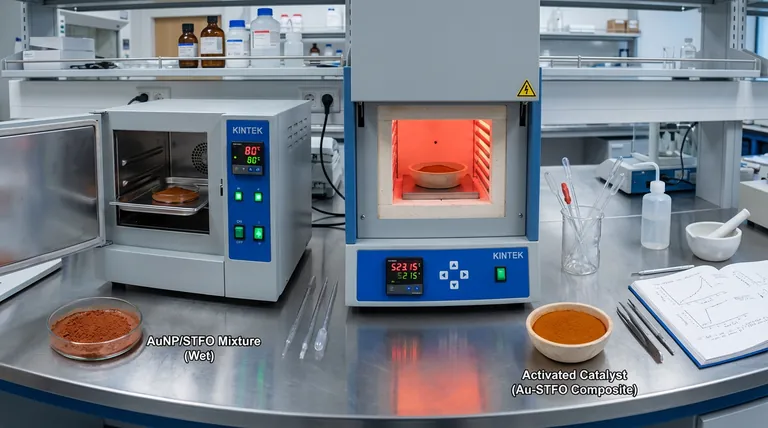

Phase 1: Physical Preparation via Drying

Removal of Process Solvents

The synthesis and loading of AuNPs involve washing steps that leave the material saturated with solvents, typically water.

The drying oven removes this residual moisture. This is a low-temperature physical process designed to dehydrate the powder without altering its chemical structure.

Preparing for High Heat

Removing bulk moisture is a safety and stability prerequisite before subjecting the material to higher temperatures.

Attempting to calcinate a wet sample can lead to rapid steam generation, which may damage the material's morphology.

Phase 2: Chemical Activation via Calcination

Elimination of Organic Residues

The loading process utilizes organic protective agents and reducing agents to stabilize the nanoparticles during synthesis.

Calcination, often performed at temperatures around 523.15 K, burns off these organic remnants. If left on the material, these agents would act as contaminants, blocking the active sites on the gold surface.

Cleaning the Nanoparticle Surface

For a catalyst to function, the surface of the gold nanoparticle must be exposed to the reaction medium.

The high heat of the calcination furnace effectively "cleans" the surface of the AuNPs. This ensures maximum exposure of the metal active sites for future catalytic reactions.

Phase 3: Engineering the Interface

Strengthening Interfacial Bonding

Mere physical deposition of gold onto a carrier is not sufficient for robust performance; the two materials must be electronically linked.

The thermal energy strengthens the bonding between the metal (Au) and the perovskite carrier (STFO). This creates a stable composite structure that can withstand operational stress.

Formation of the Schottky Junction

The ultimate goal of this thermal treatment is the modification of electronic properties.

The strong interfacial bond facilitates the formation of a Schottky junction. This electronic barrier is essential for enhancing charge transfer efficiency, allowing the catalyst to utilize energy effectively.

Understanding the Trade-offs

The Risk of Incomplete Calcination

If the calcination temperature or duration is insufficient, organic agents will remain on the surface.

This results in "poisoned" active sites. The presence of residual organics insulates the nanoparticles, preventing the necessary contact between reactants and the catalyst, thereby drastically reducing performance.

The Necessity of Bond Formation

Skipping the high-temperature step results in weak adhesion between the gold and the carrier.

Without the strong interfacial bonding promoted by calcination, the charge transfer efficiency drops. The material fails to act as a cohesive unit, negating the benefits of the STFO carrier.

Making the Right Choice for Your Goal

To ensure your AuNP/STFO composite performs as intended, consider these distinct objectives during thermal treatment:

- If your primary focus is Surface Purity: Ensure the calcination reaches sufficient temperatures (e.g., 523.15 K) to fully degrade and remove all organic protective and reducing agents.

- If your primary focus is Electronic Efficiency: Prioritize the calcination step to establish a robust Schottky junction, which is the key driver for superior charge transfer.

- If your primary focus is Structural Integrity: Do not skip the drying phase, as gradual moisture removal protects the material morphology before high-heat treatment.

The calcination furnace is not just a drying tool; it is an engineering instrument that builds the electronic bridge between your metal and your carrier.

Summary Table:

| Process Phase | Equipment Used | Primary Function | Key Outcome |

|---|---|---|---|

| Physical Preparation | Drying Oven | Low-temp moisture evaporation | Prevents morphology damage from rapid steam |

| Chemical Activation | Calcination Furnace | Removal of organic residues/stabilizers | Unblocks active sites on gold surface |

| Interface Engineering | Calcination Furnace | Strengthening Au-STFO bonding | Formation of Schottky junction for charge transfer |

Elevate Your Catalyst Performance with KINTEK

Precise thermal control is the difference between a simple mixture and a high-performance functional catalyst. At KINTEK, we provide the specialized heating solutions required for delicate material activation.

Backed by expert R&D and manufacturing, we offer high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the specific temperature profiles of your AuNP/STFO research.

Ready to achieve superior surface purity and electronic efficiency? Contact us today to find your custom furnace solution!

Visual Guide

References

- Jesús Valdés‐Hernández, María de los Ángeles Cuán-Hernandez. Photocatalytic Enhancement for CO<sub>2</sub> Reduction Using Au Nanoparticles Supported on Fe‐Doped SrTiO<sub>3−<i>δ</i></sub> Perovskite. DOI: 10.1002/solr.202300968

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What function does a box-type high-temperature furnace serve in converting precursors? Unlock Phase Homogeneity.

- Why is the size of the furnace important when selecting a muffle furnace? Ensure Precise Heating and Efficiency

- What is the function of a laboratory high-temperature furnace in cook-off synthesis? A Precise Thermal Initiator

- How is economical operation achieved in Box Furnaces? Cut Costs with Efficient Thermal Engineering

- What role do muffle furnaces play in materials research? Unlock Precise Heat Treatment for Your Lab

- What are the common industrial applications of muffle furnaces? Unlock Precision Heating for Your Lab

- What is the role of a high-temperature muffle furnace in treating Mn3O4 nanowires? Optimize Phase Stability

- What are the key considerations when selecting a muffle furnace? Ensure Optimal Performance for Your Lab