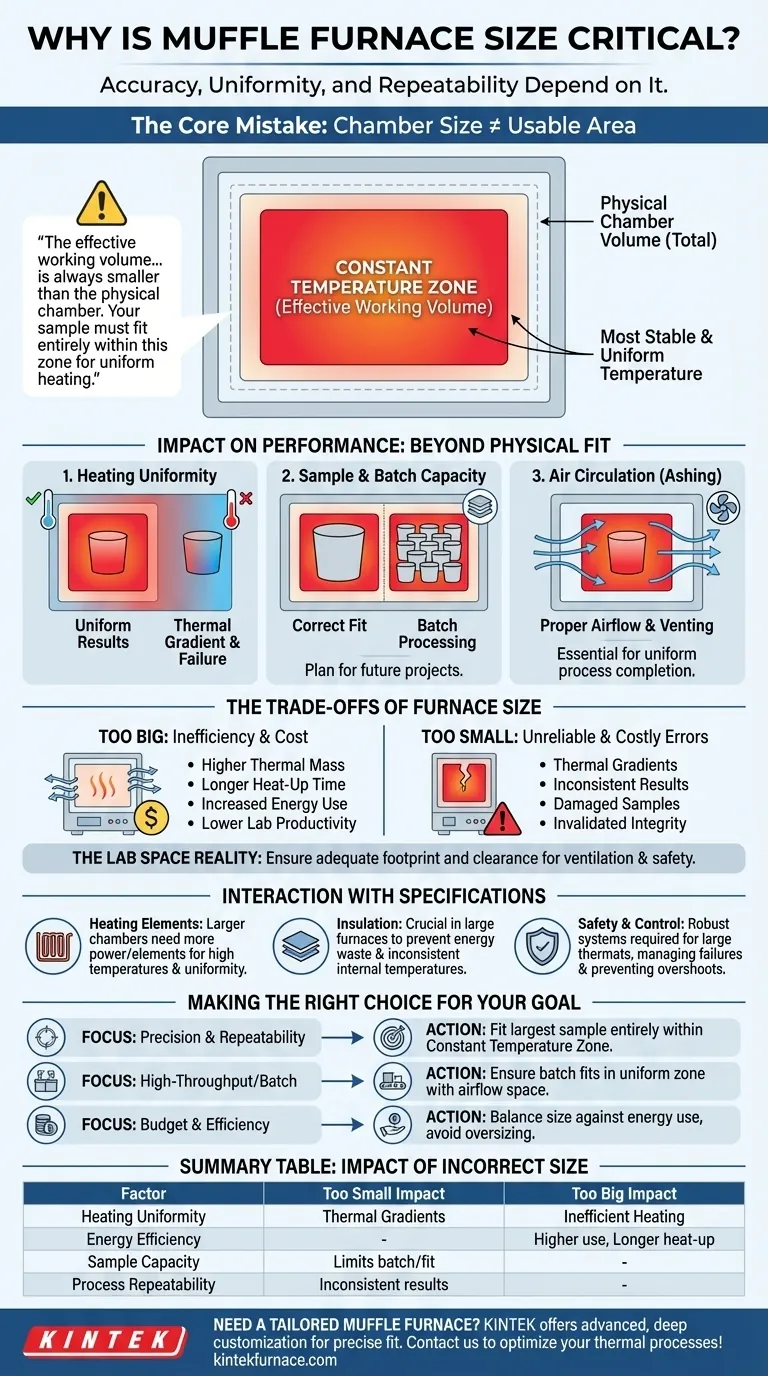

At its core, selecting the right muffle furnace size is a critical decision that goes far beyond simply fitting the unit in your lab space. The internal chamber dimensions directly dictate the accuracy, uniformity, and repeatability of your heating processes. Choosing incorrectly can lead to inconsistent results, damaged samples, and wasted energy.

The most crucial mistake to avoid is equating the furnace's internal chamber size with its usable heating area. The effective working volume, known as the constant temperature zone, is always smaller than the physical chamber, and your sample must fit entirely within this zone to ensure uniform heating.

Beyond Physical Fit: Why Chamber Size Dictates Performance

Understanding the technical implications of furnace volume is the key to making an informed decision. The size is not just a dimension; it's a primary factor in thermal performance.

The Critical Concept: Chamber vs. Constant Temperature Zone

Every muffle furnace has a physical internal chamber, but the temperature is not perfectly uniform from wall to wall. The area in the center of the chamber that maintains the most stable and uniform temperature is called the constant temperature zone.

This effective heating zone is always smaller than the chamber's listed dimensions. Reputable manufacturers will specify the size of this zone, which is the true measure of the furnace's usable capacity.

The Impact on Heating Uniformity

Placing a sample that is too large for the constant temperature zone is a recipe for failure. Any part of the material extending outside this zone will be exposed to a different temperature, creating a thermal gradient.

This inconsistency can ruin experiments, create weak spots in materials, or lead to incomplete ashing. For precise and repeatable results, your workpiece must be significantly smaller than the chamber to fit comfortably within this uniform heating area.

Accommodating Sample Size and Batch Volume

The most obvious consideration is ensuring the furnace can hold your largest sample or a full batch of smaller items. It is essential to plan not only for current needs but also for potential future projects that may require more capacity.

A furnace that is too small will permanently limit the scale and scope of work you can perform.

Air Circulation and Atmosphere

For processes like ashing, where airflow is necessary, the space around the sample is critical. An appropriately sized chamber provides adequate clearance for proper air circulation, ensuring gases are vented efficiently and the process completes uniformly.

Understanding the Trade-offs of Furnace Size

Choosing a furnace size is a balancing act. Both "too big" and "too small" come with significant downsides that affect efficiency, cost, and results.

The Cost of "Too Big"

A larger-than-necessary furnace is inefficient. It has a greater thermal mass, requiring more energy and a longer heat-up time to reach its target temperature. This translates directly to higher operational costs and lower lab productivity.

The Constraints of "Too Small"

As discussed, a furnace that is too small to contain your sample within its constant temperature zone will produce unreliable and non-uniform results. It is the most common and costly sizing error, as it invalidates the integrity of the thermal process.

The Lab Space Reality

Finally, the furnace's external footprint must be considered. Ensure you have adequate physical space in your lab, including necessary clearance on all sides for proper ventilation, user safety, and maintenance access.

How Size Interacts with Other Furnace Specifications

Furnace size does not exist in a vacuum. It is directly linked to other key design features that work together to determine overall performance.

Temperature Range and Heating Elements

Larger chambers require more powerful or more numerous heating elements to achieve high temperatures and maintain uniformity across the entire volume. The placement of these elements is critical to defining the size and shape of the constant temperature zone.

Insulation and Energy Efficiency

The quality of the furnace's insulation becomes exponentially more important as size increases. Poor insulation in a large furnace leads to significant energy waste, inconsistent internal temperatures, and an uncomfortable amount of heat being released into the lab environment.

Safety and Control Systems

A large furnace represents a significant thermal mass. This necessitates robust safety features like over-temperature protection and automatic shut-offs to manage failures safely. The temperature controller must also be sophisticated enough to manage the larger volume without significant temperature overshoots or fluctuations.

Making the Right Choice for Your Goal

To select the correct furnace, anchor your decision in your primary application.

- If your primary focus is process precision and repeatability: Choose a furnace where your largest sample fits comfortably within the manufacturer's specified constant temperature zone, not just the chamber.

- If your primary focus is high-throughput or batch processing: Select a chamber size that accommodates your maximum batch volume while ensuring all items remain within the uniform heating zone, with adequate space for circulation.

- If your primary focus is budget and operational efficiency: Carefully balance chamber size against energy consumption and heat-up times, avoiding an oversized furnace for consistently small-scale work.

By understanding that effective size is about uniform heating, not just physical space, you can select a furnace that delivers reliable and accurate results every time.

Summary Table:

| Factor | Impact of Incorrect Size |

|---|---|

| Heating Uniformity | Too small: Thermal gradients; too big: Inefficient heating |

| Energy Efficiency | Too big: Higher energy use and longer heat-up times |

| Sample Capacity | Too small: Limits batch size and sample fit |

| Process Repeatability | Incorrect size leads to inconsistent results |

Need a muffle furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your experimental requirements, enhancing accuracy and efficiency. Contact us today to discuss how we can optimize your thermal processes!

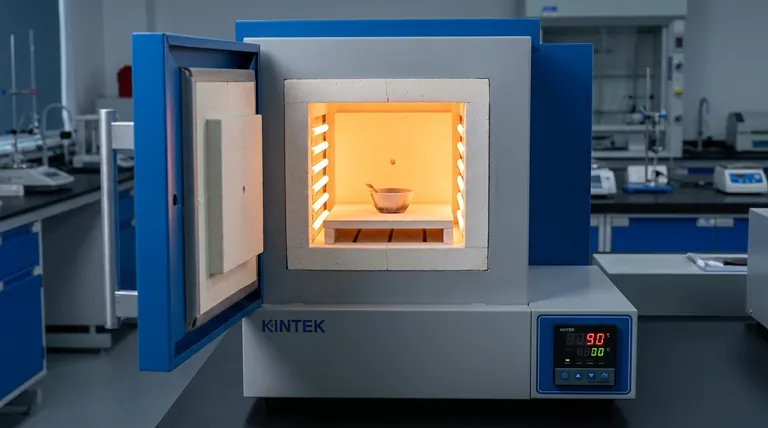

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing