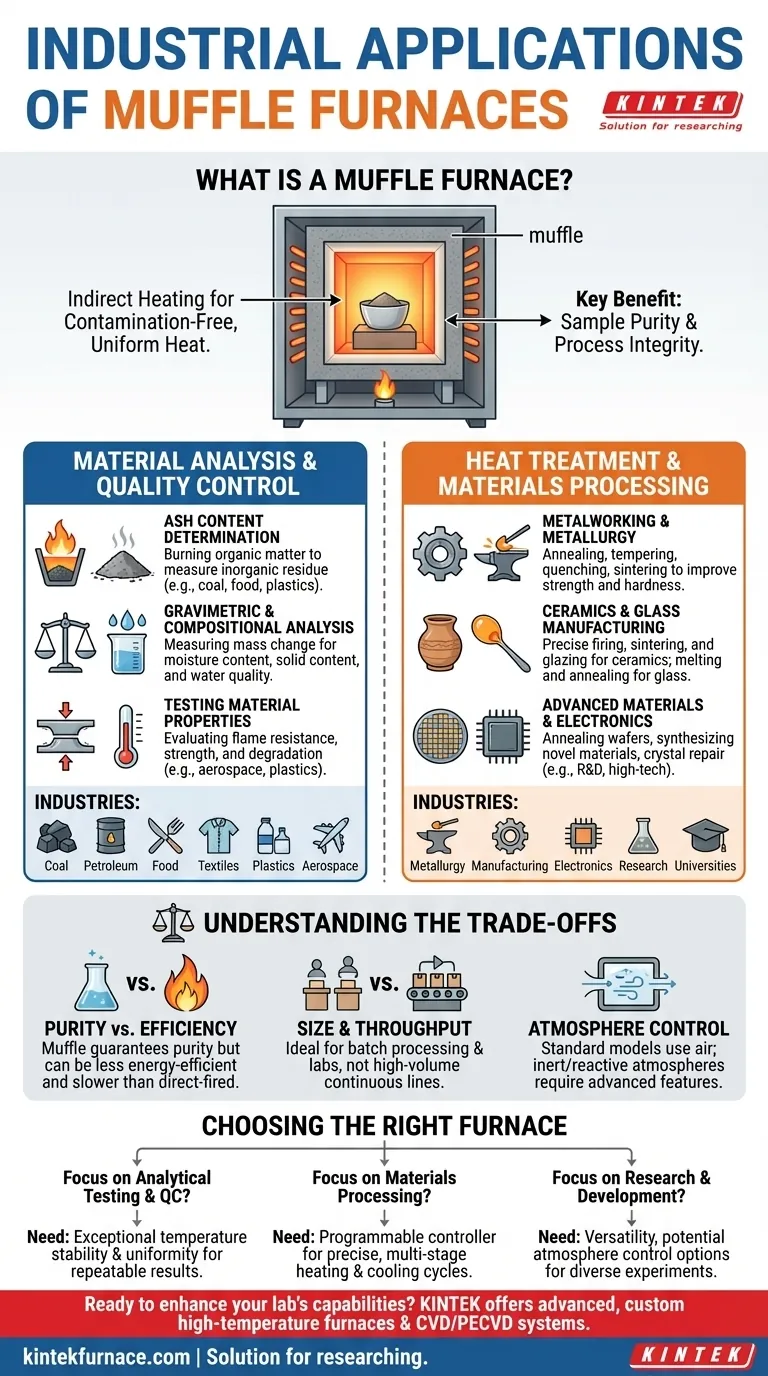

At its core, a muffle furnace is a high-temperature oven used across nearly every industrial sector for processes requiring precise, uniform heat in a contamination-free environment. Its most common applications are in metallurgy for heat-treating metals, in analytical chemistry for determining the ash content of materials, and in manufacturing for firing ceramics and glass. The furnace's defining characteristic is its ability to heat a material without any direct contact from flames or heating elements, which is critical for sample purity and process integrity.

The essential value of a muffle furnace comes from its "muffle"—an insulating chamber that isolates the workpiece from the source of heat. This separation prevents contamination from fuel byproducts and ensures uniform thermal radiation, making it the definitive tool for sensitive analytical testing and high-precision materials processing.

Material Analysis and Quality Control

A primary driver for the widespread adoption of muffle furnaces is their role in testing and verifying material composition. The furnace's controlled environment is non-negotiable for obtaining accurate results.

Ash Content Determination

Ashing is the process of burning a sample at a high temperature to remove all organic and volatile substances, leaving only the non-combustible inorganic residue (ash).

This is a fundamental quality control step in industries like coal and petroleum analysis, food production, textiles, and plastics to determine the percentage of filler or inorganic content. A muffle furnace is ideal because it prevents contaminants from the heating source from being deposited into the sample, which would skew the final weight.

Gravimetric and Compositional Analysis

Beyond ashing, these furnaces are used for other forms of gravimetric analysis where a material's properties are determined by measuring changes in mass after heating.

This includes determining the optimal moisture content in grains, analyzing water quality, or performing drying tests on paints and coatings to measure the solid content.

Testing Material Properties

Exposing materials to controlled high temperatures is a key way to test their performance and durability.

In the aerospace industry, muffle furnaces are used for flame resistance testing on components. In the plastics industry, they help evaluate material strength and degradation under thermal stress.

Heat Treatment and Materials Processing

The second major category of applications involves altering the physical properties of a material through carefully controlled heating and cooling cycles.

Metalworking and Metallurgy

Muffle furnaces are indispensable for the heat treatment of metals to improve their strength, hardness, and ductility.

Key processes include annealing (softening metal), tempering (increasing toughness), quenching (rapid cooling to harden), and sintering (fusing powdered metal into a solid mass). The uniform heat ensures the entire workpiece achieves the desired properties without surface contamination or oxidation from direct flame impingement.

Ceramics and Glass Manufacturing

The production of ceramics, from dental crowns to industrial components, relies on firing processes that require precise temperature control. A muffle furnace provides the slow, programmable temperature ramps and soaking periods needed to properly fire, sinter, and glaze ceramic materials without causing cracks or defects.

Similarly, in glass manufacturing, these furnaces are used for melting, fusing, and annealing to relieve internal stresses.

Advanced Materials and Electronics

In high-tech sectors, cleanliness is paramount. Muffle furnaces are used for processes like annealing semiconductor wafers to repair crystal damage.

Research institutions and universities use them extensively for synthesizing novel materials, processing advanced ceramics, and conducting a wide range of thermal experiments where a pristine environment is critical.

Understanding the Trade-offs

While incredibly versatile, the muffle furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Purity vs. Direct-Fired Efficiency

The muffle's primary benefit is isolating the sample, guaranteeing purity. However, this indirect heating method is often less energy-efficient and can have slower heating rates compared to a direct-fired furnace where the flame makes direct contact with the material.

Size and Throughput Limitations

Most muffle furnaces are designed for batch processing and are typically smaller in scale. They are perfect for laboratories, R&D, and the production of small, high-value parts but are generally not suited for high-volume, continuous manufacturing lines.

Atmosphere Control Complexity

A standard muffle furnace isolates the sample from combustion byproducts, but it does not inherently control the atmosphere inside the chamber (which is typically just air). Creating a specific inert (nitrogen, argon) or reactive atmosphere requires more advanced and costly models equipped with gas ports and sealed chambers.

Making the Right Choice for Your Application

Selecting the right thermal processing equipment depends entirely on your primary goal.

- If your primary focus is analytical testing and quality control: You need a furnace that provides exceptional temperature stability and uniformity to ensure repeatable ashing, drying, or ignition results.

- If your primary focus is materials processing like heat treating or firing: Prioritize a model with a programmable controller that allows for precise, multi-stage temperature ramps and soaking cycles.

- If your primary focus is research and development: Seek a versatile furnace, potentially with options for atmosphere control (e.g., inert gas ports) to accommodate a wide range of experimental needs.

By understanding these core functions and trade-offs, you can see the muffle furnace not just as a piece of equipment, but as a fundamental tool for material transformation and analysis.

Summary Table:

| Application Category | Key Uses | Industries Benefited |

|---|---|---|

| Material Analysis | Ash content determination, gravimetric analysis, material testing | Coal, petroleum, food, textiles, plastics, aerospace |

| Heat Treatment | Annealing, tempering, sintering of metals, ceramics, glass | Metallurgy, manufacturing, electronics, research |

| Advanced Processing | Semiconductor annealing, material synthesis | R&D, universities, high-tech sectors |

Ready to enhance your lab's capabilities with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior performance and reliability. Don't settle for less—contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity