In short, economical operation in a box furnace is achieved by minimizing wasted energy and maximizing process efficiency. This is accomplished through a combination of three critical engineering elements: high-quality insulation, precise airflow management, and intelligent control programming.

True furnace economy is not found in the initial purchase price, but in the total cost of ownership. It is a direct result of superior thermal engineering that reduces energy consumption, shortens cycle times, and improves product quality over the furnace's entire lifespan.

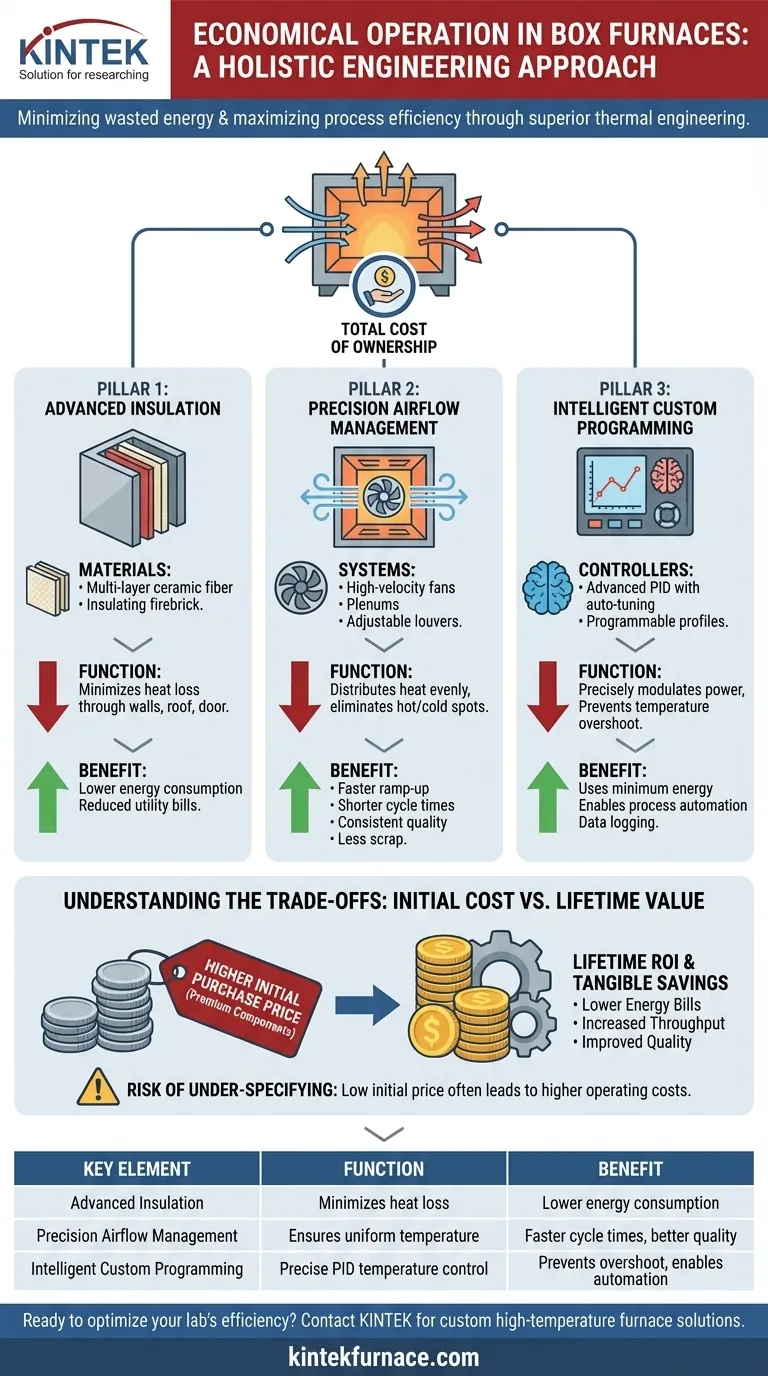

The Three Pillars of Furnace Economy

The phrase "superior thermal process engineering" refers to a holistic design approach. Economical operation isn't a single feature, but the outcome of three core pillars working in unison to control and conserve heat.

Pillar 1: Advanced Insulation

The most significant source of wasted energy in any furnace is heat loss through its walls, roof, and door. Advanced insulation directly combats this loss.

Modern furnaces utilize state-of-the-art materials like multi-layer ceramic fiber insulation and insulating firebrick. These materials have extremely low thermal conductivity, effectively trapping heat inside the chamber.

By minimizing heat leakage, the furnace's heating elements don't have to work as hard or as often to maintain the target temperature. This directly translates to lower energy consumption and reduced utility bills.

Pillar 2: Precision Airflow Management

Heat that is generated must be distributed evenly throughout the chamber. Poor airflow creates hot and cold spots, leading to inconsistent product results and longer cycle times as you wait for the coldest part to reach temperature.

Economical furnaces use sophisticated airflow management systems. This can include high-velocity circulation fans, specially designed plenums, and adjustable louvers or baffles.

The goal is to create high-volume, uniform airflow that ensures temperature uniformity across the entire workload. This leads to faster ramp-up times, shorter soak periods, and a more consistent, higher-quality end product with less scrap.

Pillar 3: Intelligent Custom Programming

How a furnace is controlled is just as important as how it is built. Basic on/off controllers are inefficient, often overshooting the temperature setpoint, which wastes significant energy and can damage sensitive parts.

Modern furnaces use advanced PID controllers (Proportional-Integral-Derivative) with auto-tuning capabilities. These controllers "learn" the thermal characteristics of the furnace and precisely modulate power to the heating elements.

This intelligent control prevents temperature overshoot, allows for programmable ramp and soak profiles, and ensures the process uses the minimum energy required to achieve the desired result. Custom programming also enables process automation and data logging for continuous improvement.

Understanding the Trade-offs: Initial Cost vs. Lifetime Value

While these advanced features are key to economy, they come with important considerations. A furnace is a long-term capital investment, and the decision should be based on lifetime value, not just the upfront price tag.

The Upfront Investment

Furnaces equipped with superior insulation, precision airflow systems, and advanced PID controllers will have a higher initial purchase price than basic models. These are premium components that add to the manufacturing cost.

Calculating the Return on Investment (ROI)

The higher initial cost is an investment that pays dividends over time. The ROI comes from tangible savings:

- Lower Energy Bills: Reduced heat loss and efficient control directly lower monthly electricity or gas costs.

- Increased Throughput: Faster cycle times from uniform heating mean you can process more product in the same amount of time.

- Improved Quality: High temperature uniformity reduces product rejects, rework, and scrap, saving material and labor costs.

The Risk of "Under-Specifying"

Choosing a furnace based solely on the lowest initial price is a common pitfall. A poorly insulated or controlled furnace will have consistently higher operating costs that can quickly surpass any initial savings, ultimately making it the more expensive option over its operational life.

Making the Right Choice for Your Goal

Select a furnace by matching its engineering strengths to your primary operational objective.

- If your primary focus is minimizing long-term operating costs: Prioritize the quality, type, and thickness of the furnace's insulation package above all else.

- If your primary focus is maximum throughput and part consistency: Focus on furnaces with documented temperature uniformity and robust, high-volume airflow management systems.

- If your primary focus is process versatility and precision: The sophistication of the control system and its custom programming capabilities should be your top priority.

Ultimately, an informed furnace purchase is one that balances initial cost against the long-term savings generated by superior engineering.

Summary Table:

| Key Element | Function | Benefit |

|---|---|---|

| Advanced Insulation | Minimizes heat loss with ceramic fiber or firebrick | Lower energy consumption and utility costs |

| Precision Airflow Management | Ensures uniform temperature distribution | Faster cycle times, improved product quality, less scrap |

| Intelligent Custom Programming | Uses PID controllers for precise temperature control | Prevents overshoot, reduces energy use, enables automation |

Ready to optimize your lab's efficiency with a custom high-temperature furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering long-term savings and enhanced performance. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution