In modern dentistry, the dental porcelain furnace is the critical instrument that transforms raw ceramic materials into strong, durable, and lifelike dental restorations. These furnaces are not merely ovens; they are sophisticated, programmable devices that provide the precise control over temperature, time, and atmosphere necessary to achieve the specific physical and aesthetic properties required for crowns, bridges, and veneers.

The importance of a dental porcelain furnace lies not just in its ability to heat materials, but in its function as a tool of material science. It enables the precise manipulation of ceramic structures at a microscopic level, ensuring the final restoration is both strong enough for daily function and aesthetically indistinguishable from a natural tooth.

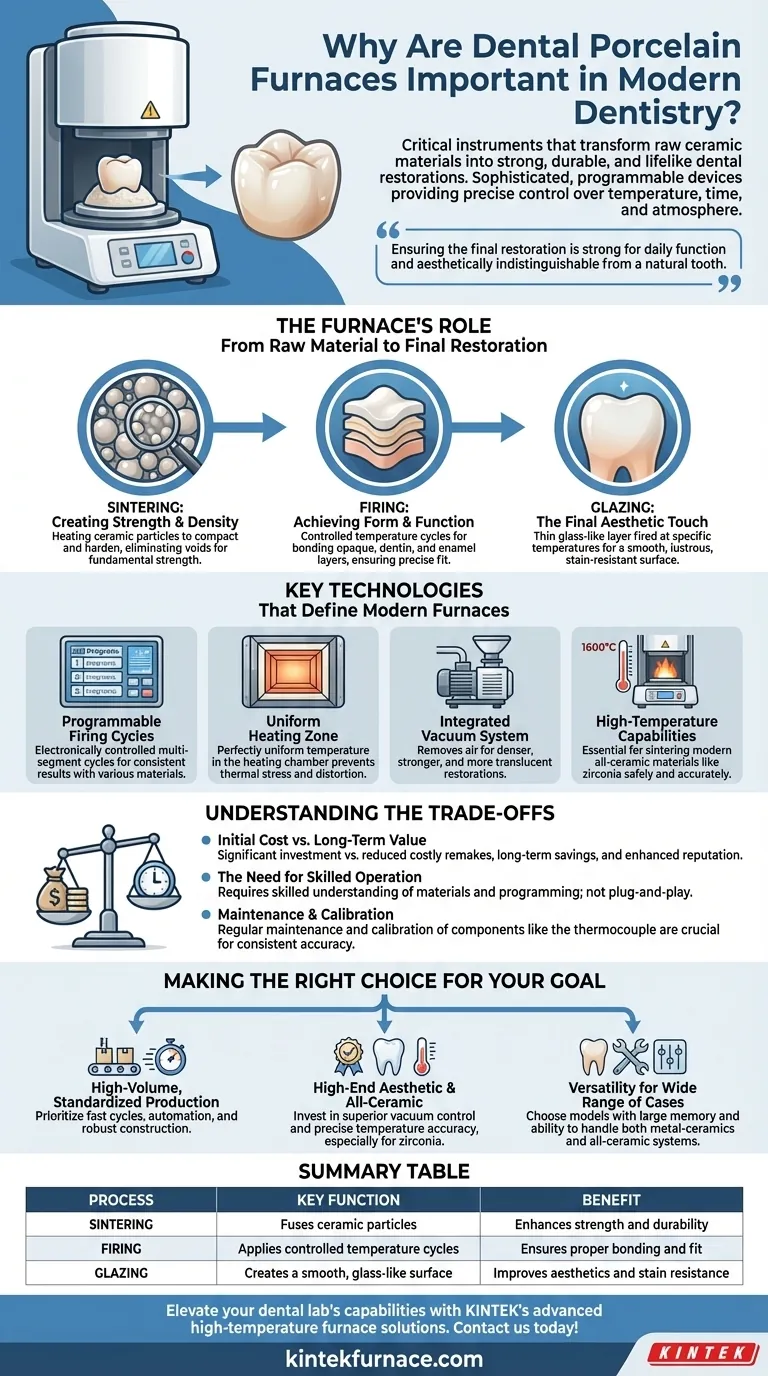

The Furnace's Role: From Raw Material to Final Restoration

A dental furnace is where the artistry of a dental technician meets the science of ceramics. It facilitates several key processes that are non-negotiable for producing high-quality work.

Sintering: Creating Strength and Density

Sintering is the process of heating ceramic particles to a temperature just below their melting point.

This causes the particles to fuse, compacting the material, eliminating voids, and creating a dense, hardened structure. This step is what gives a restoration its fundamental strength and durability.

Firing: Achieving Form and Function

Firing cycles involve carefully controlled temperature ramps and holds. Different stages of firing are used to build up layers of porcelain, such as opaque, dentin, and enamel layers, mimicking the structure of a natural tooth.

Each layer requires a specific firing program to bond correctly without warping or cracking, ensuring the final restoration fits the patient's mouth perfectly.

Glazing: The Final Aesthetic Touch

The final step is often a glaze fire. A thin layer of glass-like porcelain is applied and fired at a specific temperature.

This creates a smooth, lustrous, and non-porous surface that not only looks natural but also resists staining and plaque accumulation, contributing to better oral hygiene.

Key Technologies That Define Modern Furnaces

The effectiveness of a dental furnace comes down to specific technological features that provide absolute control over the firing process.

Programmable Firing Cycles

Modern furnaces are electronically controlled and allow technicians to program, save, and execute multi-segment firing cycles.

Because different materials like zirconia, lithium disilicate, and metal-ceramics each require unique heating rates, hold times, and cooling periods, this programmability is essential for achieving consistent, predictable results.

Uniform Heating Zone

A high-quality muffle (the heating chamber) provides a zone of perfectly uniform temperature.

This ensures the entire restoration, regardless of its position on the firing tray, is heated evenly. This uniformity is critical for preventing thermal stress, distortion, and ensuring a precise fit.

Integrated Vacuum System

Many firing processes are performed under a vacuum. The vacuum pump removes air from the muffle before and during the heating cycle.

This eliminates air bubbles and impurities from within the porcelain, resulting in a denser, stronger, and more translucent restoration that better mimics the vitality of a natural tooth.

High-Temperature Capabilities

The rise of all-ceramic materials, particularly zirconia, has made high-temperature capabilities essential. Sintering zirconia requires temperatures up to 1600°C.

A furnace's ability to safely and accurately reach these temperatures determines its suitability for a modern, all-ceramic workflow.

Understanding the Trade-offs

While indispensable, investing in and operating a dental furnace involves important considerations that impact a dental laboratory's workflow and finances.

Initial Cost vs. Long-Term Value

Advanced dental furnaces represent a significant capital investment. However, their precision drastically reduces the rate of costly remakes.

By producing durable and accurate restorations the first time, a reliable furnace provides significant long-term cost savings and enhances the lab's reputation.

The Need for Skilled Operation

These are not "plug-and-play" devices. A skilled dental technician must understand the properties of each ceramic material and how to program the furnace accordingly.

Incorrect programming can easily ruin a restoration, wasting both time and expensive materials. Consistent training is key to leveraging the furnace's full potential.

Maintenance and Calibration

To maintain accuracy, furnaces require regular maintenance and calibration. The thermocouple, which measures temperature, can degrade over time and must be checked or replaced.

Failure to maintain the furnace can lead to inaccurate firing temperatures, compromising the quality and consistency of every restoration produced.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the primary focus of your dental lab or practice.

- If your primary focus is high-volume, standardized production: Prioritize a furnace known for its fast firing cycles, automation features, and robust, reliable construction.

- If your primary focus is high-end aesthetic and all-ceramic restorations: Invest in a furnace with superior vacuum control and precise temperature accuracy, especially in the high ranges required for zirconia.

- If your primary focus is versatility for a wide range of cases: Choose a model with a large memory for programmable cycles and a proven ability to handle both metal-ceramics and various all-ceramic systems.

Ultimately, the dental porcelain furnace empowers the modern dental professional to deliver on the highest promise of restorative dentistry: to create replacements that perfectly restore both function and confidence.

Summary Table:

| Process | Key Function | Benefit |

|---|---|---|

| Sintering | Fuses ceramic particles | Enhances strength and durability |

| Firing | Applies controlled temperature cycles | Ensures proper bonding and fit |

| Glazing | Creates a smooth, glass-like surface | Improves aesthetics and stain resistance |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs for precise, efficient restorations. Contact us today to discuss how we can enhance your workflow and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations