In short, box-type high-temperature resistance furnaces are exceptionally versatile, designed to accommodate a wide spectrum of workpieces. Their spacious and regularly shaped interiors allow for the flexible arrangement of everything from small, intricate precision parts to large, bulky molds, making them a flexible solution for many heat treatment applications.

The true value of a box-type furnace is not just its physical capacity but its ability to process a diverse range of materials for demanding applications. This is made possible by its wide operational temperature range and high-precision thermal control.

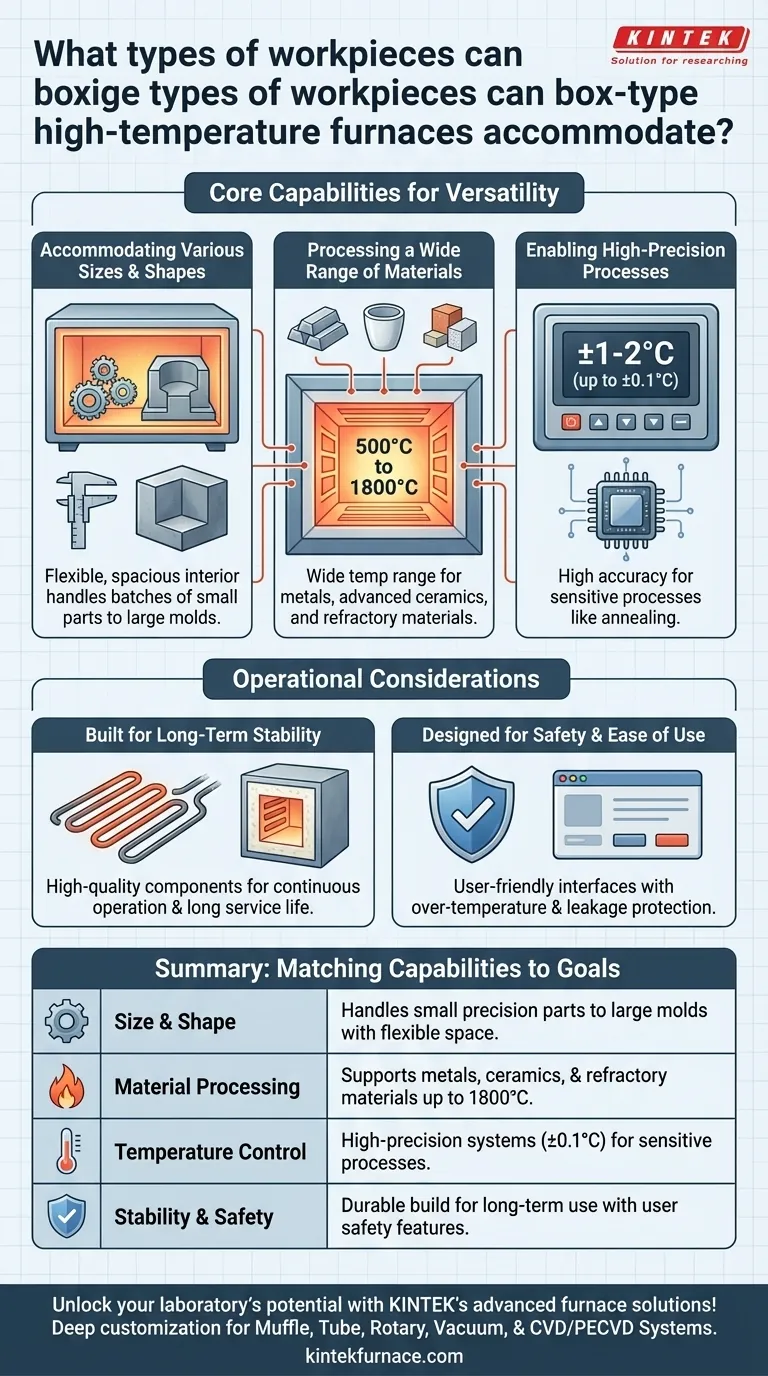

Understanding the Furnace's Core Capabilities

To determine if this furnace is right for your work, you must look beyond simple dimensions and evaluate its performance characteristics. The suitability of a workpiece is defined by its size, material composition, and the specific heat treatment process it requires.

Accommodating Various Sizes and Shapes

The defining physical feature of a box-type furnace is its large and regularly shaped interior space.

This design is intentional, providing maximum flexibility for loading and arranging items. It easily handles batches of small, complex components or single, large workpieces like industrial molds.

Processing a Wide Range of Materials

These furnaces are defined by a wide operational temperature range, generally between 500°C and 1800°C.

This thermal capacity allows them to meet the demanding heat treatment requirements of many different material classes, including ordinary metals, advanced ceramics, and refractory metals.

Enabling High-Precision Processes

Modern box-type furnaces are equipped with high-precision temperature control systems.

With advanced sensors, they can typically achieve a temperature control accuracy of ±1-2°C. Some high-precision models are even capable of maintaining an accuracy of ±0.1°C, which is critical for sensitive processes like semiconductor material annealing.

Key Operational Considerations

A furnace's utility is also measured by its reliability and ease of use in a professional setting. These factors ensure consistent results and a safe working environment.

Built for Long-Term Stability

These furnaces are constructed with high-quality heating elements and insulation materials.

These components feature high temperature and oxidation resistance, ensuring a long service life and the ability to operate continuously for extended periods, which helps reduce production downtime.

Designed for Operator Safety and Ease of Use

Despite their power, these systems feature user-friendly interfaces that simplify operation.

Basic training is all that is required to learn how to start, stop, and set temperatures. Crucially, they include integrated safety protections like over-temperature alarms and leakage protection to ensure both operator safety and equipment reliability.

Making the Right Choice for Your Application

To select the correct furnace, you must align its specifications with your primary operational goal. Consider what aspect of performance is most critical for your work.

- If your primary focus is processing diverse shapes and sizes: Confirm the furnace's internal chamber dimensions provide ample, flexible space for your largest and smallest workpieces.

- If your primary focus is material versatility: Ensure the furnace's maximum temperature (up to 1800°C) is sufficient for all your target materials, from standard metals to special ceramics.

- If your primary focus is high-precision heat treatment: Prioritize a model with documented temperature control accuracy (±1-2°C or better) to meet the strict requirements of processes like annealing.

Ultimately, selecting the right furnace is about matching its capabilities in size, temperature, and control to your precise material processing goals.

Summary Table:

| Feature | Capability |

|---|---|

| Size & Shape Accommodation | Handles small precision parts to large molds with flexible interior space |

| Material Processing | Supports metals, ceramics, and refractory materials up to 1800°C |

| Temperature Control | High-precision systems with accuracy up to ±0.1°C for sensitive processes |

| Operational Stability | Built with durable heating elements and insulation for long-term use |

| Safety & Usability | User-friendly interfaces with over-temperature and leakage protection |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your material processing efficiency and reliability!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability