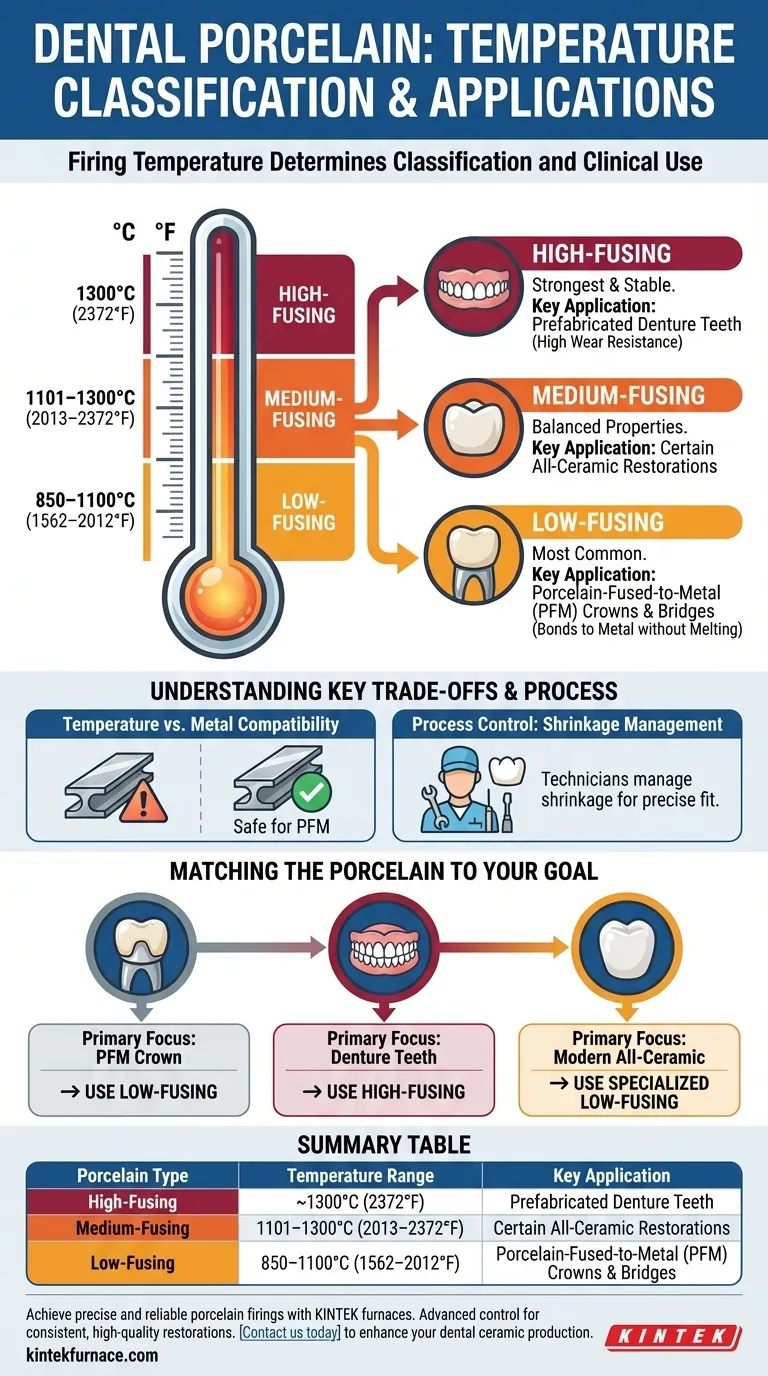

The temperature of dental porcelain is not a single value but a range that defines its classification and use. Dental porcelains are categorized as high-fusing (around 1300°C / 2372°F), medium-fusing (1101-1300°C / 2013-2372°F), or low-fusing (850-1100°C / 1562-2012°F), with each class suited for different clinical applications.

The critical takeaway is that a porcelain's firing temperature is its most important technical property. This temperature dictates not only its classification but, more importantly, what it can be used for—from denture teeth to crowns bonded to a metal substructure.

Why Firing Temperature Dictates Application

In dental technology, the term "porcelain" refers to a family of ceramic materials. The temperature required to fire or "sinter" these materials into a dense, hard restoration is the primary factor that separates them.

This firing process transforms the fine ceramic powder into a solid, glass-like structure. The specific temperature required determines the material's final properties, including its strength, translucency, and compatibility with other materials like metal alloys.

The Standard Classification of Dental Porcelains

Manufacturers classify their porcelains into three distinct groups based on their maturation temperature. Understanding these categories is fundamental to selecting the correct material for a restoration.

High-Fusing: 1300 °C (2372 °F)

High-fusing porcelain is the strongest and most stable of the categories. Its high firing temperature results in a very dense and durable final product.

Historically, this was the primary material for manufacturing prefabricated denture teeth due to its exceptional wear resistance.

Medium-Fusing: 1101–1300 °C (2013–2372 °F)

As the name suggests, medium-fusing porcelains occupy the middle ground. They offer a balance of properties between the high- and low-fusing types.

These materials are often used for certain all-ceramic restorations where a metal substructure is not required.

Low-Fusing: 850–1100 °C (1562–2012 °F)

Low-fusing porcelain is the most commonly used type in modern restorative dentistry. Its primary application is for porcelain-fused-to-metal (PFM) crowns and bridges.

The lower firing temperature is crucial because it allows the porcelain to be bonded to a metal coping without melting or distorting the underlying metal framework.

Understanding the Key Trade-offs

Choosing a porcelain is not just about picking the "strongest" one. The decision is driven by the requirements of the final restoration, which involves critical trade-offs between temperature, strength, and application.

Temperature vs. Metal Compatibility

This is the most significant trade-off. High-fusing porcelains are very stable, but their firing temperature is too high to be safely used with the metal alloys common in dentistry.

Low-fusing porcelains were specifically developed to solve this problem, enabling the creation of strong, aesthetic PFM restorations that remain the standard of care in many situations.

Process Control and Shrinkage

All dental porcelains shrink during firing as the particles fuse together. Dental technicians must expertly manage this shrinkage to ensure the final crown or bridge fits the patient precisely.

While not a direct trade-off for the clinician, the properties associated with each temperature class, including its specific shrinkage percentage, require different handling protocols in the lab.

Matching the Porcelain to Your Goal

Your choice of porcelain must be guided by the clinical objective. The firing temperature is not an arbitrary number but a direct indicator of the material's intended purpose.

- If your primary focus is a Porcelain-Fused-to-Metal (PFM) crown: Low-fusing porcelain is the only appropriate choice to ensure the integrity of the metal substructure.

- If your primary focus is prefabricated denture teeth: High-fusing porcelain provides the best wear resistance and durability for this application.

- If your primary focus is a modern all-ceramic restoration (like Zirconia): You will be using specialized layering ceramics, which are typically in the low-fusing range, designed to bond to the ceramic core material.

Ultimately, understanding these classifications empowers you to communicate effectively with the dental laboratory and ensure the right material is used for the right clinical purpose.

Summary Table:

| Porcelain Type | Temperature Range | Key Application |

|---|---|---|

| High-Fusing | ~1300°C (2372°F) | Prefabricated Denture Teeth |

| Medium-Fusing | 1101–1300°C (2013–2372°F) | Certain All-Ceramic Restorations |

| Low-Fusing | 850–1100°C (1562–2012°F) | Porcelain-Fused-to-Metal (PFM) Crowns & Bridges |

Achieve precise and reliable porcelain firings with KINTEK furnaces. Our advanced Muffle and Vacuum & Atmosphere Furnaces offer the exact temperature control and uniform heating required for consistent, high-quality dental restorations. With our strong deep customization capability, we can tailor a furnace solution to perfectly match your lab's unique workflow and material requirements. Contact us today to discuss how we can enhance your dental ceramic production.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab

- What are the risks of inadequate dental furnace ventilation? Protect Your Lab Quality & Team Safety

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations

- What are some recent innovations in dental lab equipment furnaces? Boost Efficiency with Smart Automation

- What is the step-by-step process for making porcelain dental restorations? Master Precision and Aesthetics