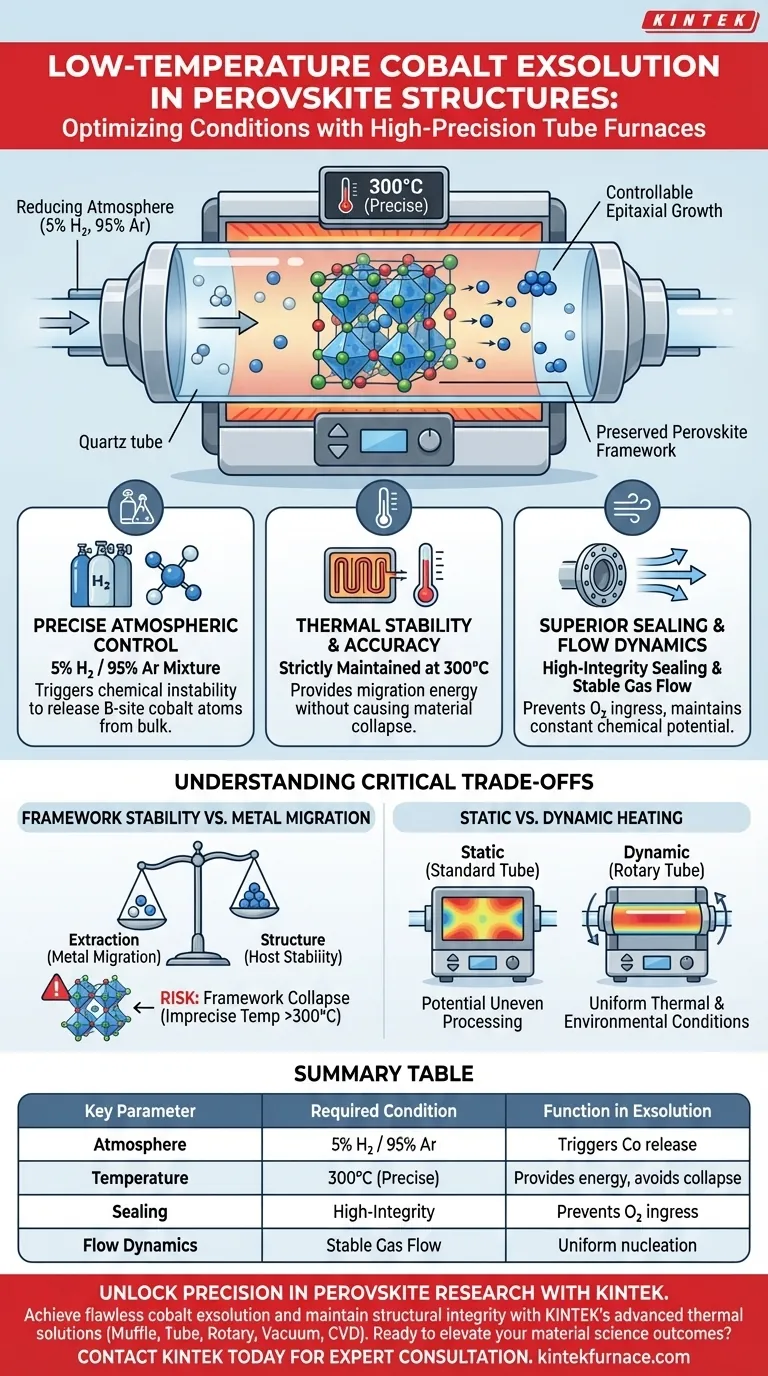

A high-precision tube furnace creates a strictly controlled reducing environment, typically utilizing a mixture of 5% hydrogen and 95% argon, to facilitate the low-temperature exsolution of cobalt. By maintaining a precise temperature of 300 degrees Celsius and a stable gas flow, the system enables the migration of cobalt atoms to the surface while preserving the structural integrity of the perovskite material.

The critical value of the tube furnace lies in its superior sealing and thermal accuracy, which allow for controllable epitaxial growth of metal atoms without causing the collapse of the underlying perovskite framework.

Optimizing the Environment for Exsolution

Precise Atmospheric Control

The fundamental requirement for exsolution is a reducing atmosphere. The tube furnace provides this by maintaining a specific gas mixture, such as 5% hydrogen and 95% argon.

This reducing environment is essential for triggering the chemical instability required to release B-site metal atoms (cobalt) from the bulk crystal lattice.

Thermal Stability and Accuracy

Low-temperature exsolution relies on maintaining a specific thermal window, cited as 300 degrees Celsius in this context.

High-precision furnaces ensure that this temperature is held constant. This accuracy provides the necessary energy for metal migration and nucleation while avoiding the higher temperatures that would degrade the material.

Sealing and Flow Dynamics

Superior sealing is a non-negotiable feature of the tube furnace for this application. It prevents the ingress of oxygen, which would inhibit the reduction process.

Furthermore, a stable flow of reducing gas ensures that the chemical potential at the surface of the perovskite remains constant, driving continuous and uniform exsolution.

Understanding the Critical Trade-offs

Framework Stability vs. Metal Migration

The process involves a delicate balance between extracting metal atoms and maintaining the host structure. The primary risk in this process is the collapse of the underlying perovskite framework.

If the temperature controls lack precision or overshoot the 300-degree target, the lattice may destabilize completely rather than supporting controlled epitaxial growth.

Static vs. Dynamic Heating

While a standard tube furnace provides excellent atmosphere control, static heating can sometimes lead to uneven processing in larger batches.

A rotary tube furnace can address this by utilizing a rotating tube to tumble the material. This ensures that every particle is exposed to uniform thermal and environmental conditions, preventing localized hotspots or incomplete reactions.

Making the Right Choice for Your Goal

To achieve successful cobalt exsolution without damaging your material, you must prioritize specific equipment capabilities based on your primary outcome.

- If your primary focus is preserving structural integrity: Prioritize a furnace with high thermal accuracy to maintain the temperature strictly at 300°C, avoiding framework collapse.

- If your primary focus is maximizing nucleation efficiency: Ensure your system supports a precise, stable flow of the 5% H2 / 95% Ar mixture to drive consistent migration from the bulk to the surface.

Precise control over the thermal and chemical environment is the only way to achieve controllable epitaxial growth in these advanced materials.

Summary Table:

| Key Parameter | Required Condition | Function in Exsolution |

|---|---|---|

| Atmosphere | 5% H₂ / 95% Ar | Triggers chemical instability to release B-site cobalt atoms |

| Temperature | 300°C (Precise) | Provides migration energy without collapsing the perovskite framework |

| Sealing | High-Integrity Vacuum/Gas Tight | Prevents oxygen ingress to maintain a reducing environment |

| Flow Dynamics | Stable Gas Flow | Maintains constant chemical potential for uniform nucleation |

Unlock Precision in Perovskite Research with KINTEK

Achieve flawless cobalt exsolution and maintain structural integrity with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, we provide Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for your most sensitive lab applications. Whether you require high thermal accuracy for epitaxial growth or uniform processing via rotary tube furnaces, our customizable systems are designed to meet your unique research needs.

Ready to elevate your material science outcomes?

Contact KINTEK Today for a Expert Consultation

Visual Guide

References

- Sang‐Mun Jung, Yong‐Tae Kim. Low‐Temperature Exsolution of Cobalt From Perovskite Nanoparticles via Bead Milling for Enhanced Electrocatalytic Oxygen Evolution Reaction. DOI: 10.1002/adfm.202506227

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- When did tube furnaces originate and what drove their development? Discover the Engineered Solution for Precise Heat

- What is the primary role of a tube furnace during pre-carbonization? Optimize Biomass-to-Hard-Carbon Conversion

- What makes a vertical tube furnace efficient and energy-saving? Unlock Superior Thermal Control & Cost Savings

- What technical conditions does a vacuum tube furnace provide for carbon xerogel? Master High-Performance Carbonization

- What are the main applications of drop tube furnaces? Unlock Precision in High-Temperature Processes

- Why is a tube furnace essential for the reduction treatment of Y-NiMo/MoO2-x? Master Precision Synthesis

- How do three-zone tube furnaces support scalability? Bridge Lab to Industrial Production Seamlessly

- What are the advantages of using industrial aluminum profiles for tube furnaces? Achieve Modular Lab Efficiency