Maintaining a dental lab furnace is crucial for its optimal performance and longevity. Regular professional servicing combined with diligent routine cleaning ensures the equipment operates efficiently, delivers consistent results, and prevents costly malfunctions in dental material processing.

Maintaining a dental lab furnace is not merely about extending its lifespan; it is fundamental to ensuring the precision, consistency, and reliability required for producing high-quality dental prosthetics. Proactive maintenance minimizes downtime, safeguards the investment, and most importantly, guarantees the accurate and repeatable results essential for patient care.

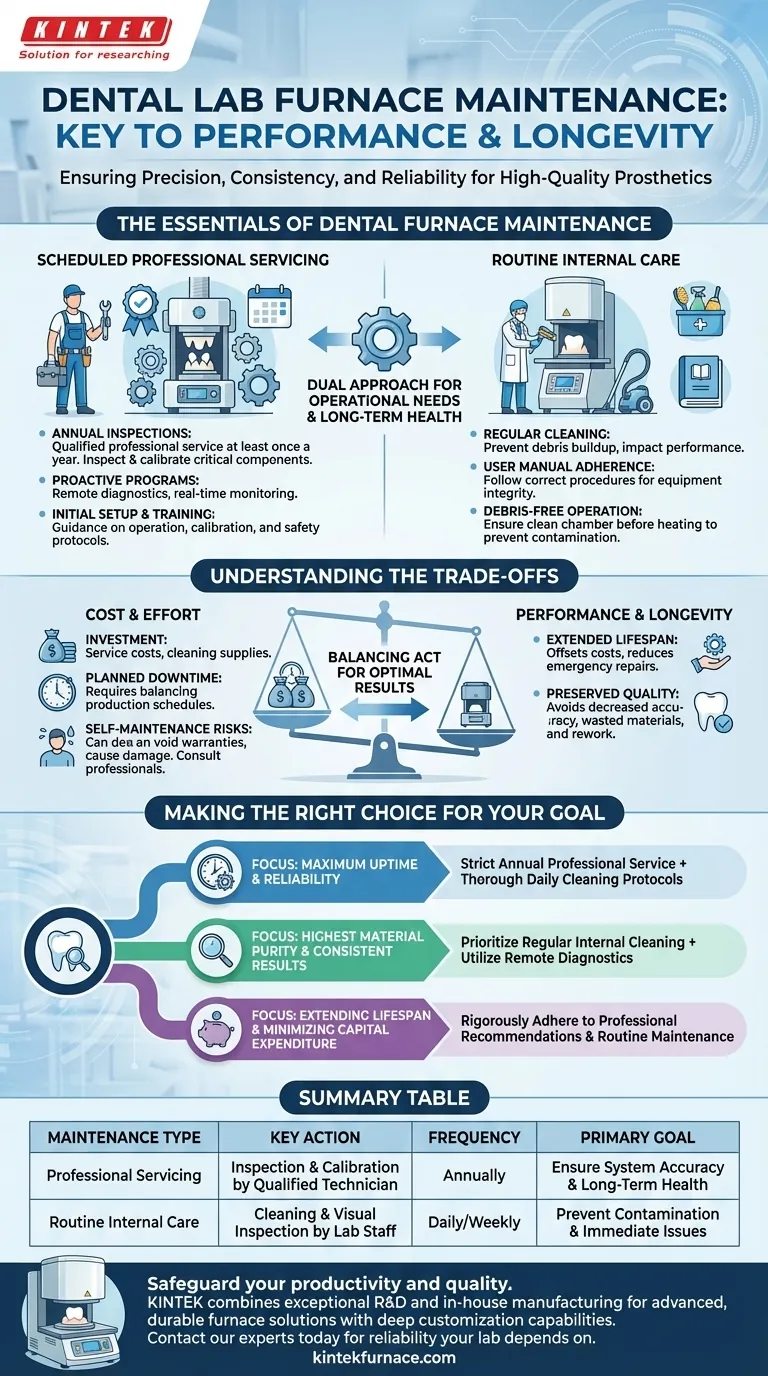

The Essentials of Dental Furnace Maintenance

Effective maintenance for a dental lab furnace encompasses both routine internal care and scheduled professional oversight. This dual approach addresses immediate operational needs and long-term system health.

Scheduled Professional Servicing

Regular professional servicing is paramount for complex laboratory equipment.

Annual Inspections are Key

It is recommended that a dental lab furnace be serviced by a qualified professional at least once a year. This ensures all critical components are inspected and calibrated.

Proactive Maintenance Programs

Some manufacturers offer after-sales service that includes proactive maintenance and calibration. This can involve remote diagnostics to monitor furnace data in real-time.

Initial Setup and Training

The service process often begins with initial setup and training. A technical support team provides guidance on operation, calibration, routine maintenance, and safety protocols.

Routine Internal Care

Beyond professional servicing, daily and weekly attention to the furnace's condition by lab staff significantly contributes to its performance.

Regular Cleaning

Regularly cleaning the furnace and its parts is essential. This helps to prevent the buildup of debris that can impact performance and longevity.

User Manual Adherence

Always review the user manual before operation or maintenance. This ensures correct procedures are followed, preserving equipment integrity.

Debris-Free Operation

Before turning on the furnace, ensure it is clean and free of any debris. This prevents contamination and potential damage during heating cycles.

Understanding the Trade-offs

While maintenance is critical, there are inherent trade-offs between cost, effort, and equipment performance that lab managers must consider.

Cost vs. Longevity

Investing in annual professional servicing and quality cleaning supplies comes with a cost. However, this is typically offset by extended equipment lifespan and reduced emergency repair expenses.

Downtime for Maintenance

Scheduled maintenance, both routine and professional, requires the furnace to be out of service. This planned downtime needs to be balanced against production schedules.

Self-Maintenance Risks

Attempting complex repairs or calibrations without professional training can void warranties or cause further damage. Always consult the user manual or a technician for intricate issues.

Performance Degradation without Maintenance

Neglecting maintenance inevitably leads to decreased accuracy and consistency. This can result in wasted materials, rework, and compromised quality of dental prosthetics.

Making the Right Choice for Your Goal

The approach to dental furnace maintenance should align with your laboratory's priorities, whether focused on uptime, precision, or cost-effectiveness.

- If your primary focus is maximum operational uptime and reliability: Establish a strict annual professional service schedule and empower staff with thorough daily cleaning protocols.

- If your primary focus is ensuring the highest material purity and consistent results: Prioritize regular internal cleaning to prevent contamination and utilize remote diagnostics if available for early detection of performance issues.

- If your primary focus is extending equipment lifespan and minimizing capital expenditure: Adhere rigorously to both professional service recommendations and routine user-level maintenance, viewing maintenance as an investment, not an expense.

Proactive and diligent maintenance is the cornerstone of a high-performing dental lab, safeguarding both your equipment and the quality of your work.

Summary Table:

| Maintenance Type | Key Action | Frequency | Primary Goal |

|---|---|---|---|

| Professional Servicing | Inspection & Calibration by a Qualified Technician | Annually | Ensure System Accuracy & Long-Term Health |

| Routine Internal Care | Cleaning & Visual Inspection by Lab Staff | Daily/Weekly | Prevent Contamination & Immediate Issues |

Safeguard your dental lab's productivity and the quality of your prosthetics. Proper maintenance starts with reliable equipment. At KINTEK, we combine exceptional R&D and in-house manufacturing to provide dental laboratories with advanced, durable furnace solutions. Our product line, including specialized dental furnaces, is backed by strong deep customization capabilities to meet your unique workflow requirements.

Contact our experts today to discuss how our furnaces and support services can provide the reliability and consistency your lab depends on.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations