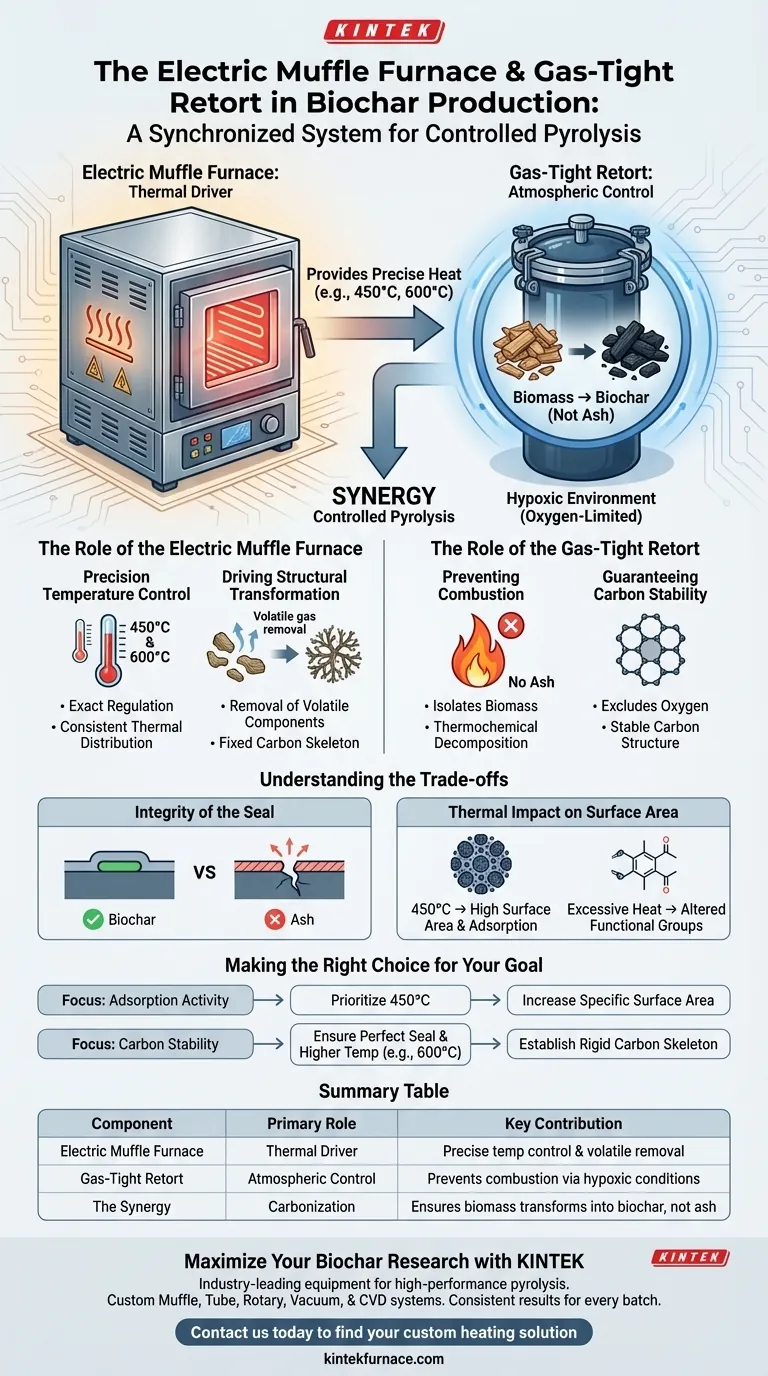

The electric muffle furnace and gas-tight retort function as a synchronized system to enable controlled pyrolysis. The furnace serves as the precise heat source that drives thermal decomposition, while the retort acts as a protective barrier, isolating the biomass from oxygen to ensure it carbonizes into biochar rather than burning into ash.

The synergy between these two components is critical: the furnace supplies the energy to restructure the biomass, but the retort's maintenance of a hypoxic environment is what ultimately guarantees carbon stability and biochar quality.

The Role of the Electric Muffle Furnace: Thermal Driver

The primary function of the electric muffle furnace is to provide a precise high-temperature environment. It acts as the engine of the process, supplying the thermal energy required to break down the chemical bonds within the raw biomass.

Precision Temperature Control

Biochar quality relies heavily on specific temperature parameters, such as maintaining 600°C for volatile removal or 450°C for surface area development. The muffle furnace allows for exact regulation of these temperatures, ensuring a consistent thermal distribution throughout the process.

Driving Structural Transformation

The heat generated by the furnace facilitates the removal of volatile components from plant residues. This process transforms the biomass into a fixed carbon skeleton, creating the preliminary porous structure essential for the biochar's final utility.

The Role of the Gas-Tight Retort: Atmospheric Control

While the furnace provides heat, the gas-tight retort creates an oxygen-limited (hypoxic) atmosphere. This component is responsible for isolating the raw material from external air during the heating phase.

Preventing Combustion

Without the retort, the high temperatures of the furnace would cause the biomass to combust and turn into ash. By isolating the material, the retort ensures that thermochemical decomposition occurs instead of burning, preserving the material's mass.

Guaranteeing Carbon Stability

The retort’s ability to exclude oxygen is the deciding factor in determining the chemical stability of the final product. It controls the pyrolysis conditions to guarantee that the resulting biochar possesses a stable carbon structure and high quality.

Understanding the Trade-offs

When operating this equipment, understanding the relationship between temperature and containment is vital for avoiding common production pitfalls.

The Integrity of the Seal

The effectiveness of the process is entirely dependent on the integrity of the retort's seal. Even a minor breach in the gas-tight environment allows oxygen infiltration, which degrades the carbon structure and reduces the yield to ash.

Thermal Impact on Surface Area

While higher temperatures in the furnace drive carbonization, they must be balanced against the desired properties of the biochar. For example, specific temperature distributions (such as 450°C) are better suited for preserving biomass integrity and increasing specific surface area and adsorption activity, whereas excessive heat might alter these functional groups.

Making the Right Choice for Your Goal

To maximize the effectiveness of your biochar production, you must tune your furnace and retort usage to your specific objectives.

- If your primary focus is Adsorption Activity: Prioritize precise lower-temperature settings (around 450°C) in the furnace to increase specific surface area and promote surface functional groups.

- If your primary focus is Carbon Stability: Ensure the retort is perfectly sealed to maintain strict hypoxic conditions, allowing for higher temperature processing (around 600°C) to establish a rigid carbon skeleton.

Success in biochar production is not just about heating biomass; it is about mastering the balance between energy application and atmospheric isolation.

Summary Table:

| Component | Primary Role | Key Contribution |

|---|---|---|

| Electric Muffle Furnace | Thermal Driver | Precise temperature control & volatile removal |

| Gas-Tight Retort | Atmospheric Control | Prevents combustion by maintaining hypoxic conditions |

| The Synergy | Carbonization | Ensures biomass transforms into biochar rather than ash |

Maximize Your Biochar Research with KINTEK

Ready to achieve superior carbon stability and precise adsorption properties? KINTEK provides the industry-leading laboratory equipment necessary for high-performance pyrolysis. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique biochar production needs.

Whether you are focusing on surface area development or structural carbonization, our precision furnaces ensure consistent results for every batch. Contact us today to find your custom heating solution and elevate your material science research.

Visual Guide

References

- João Arthur Antonângelo, Hailin Zhang. Fertilizer potential of biochar and ryegrass productivity in metal-contaminated soil. DOI: 10.3389/fpls.2024.1475939

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the significance of muffle furnaces in materials science? Unlock Pure, High-Temperature Processing

- What should be done if the silicon carbon rod in the muffle furnace's resistance furnace ages or underperforms? Expert Tips for Optimal Performance

- Why is it necessary to control the heating rate of a muffle furnace during calcination? Optimize Bioactive Glass Quality

- What is the function of a laboratory box resistance furnace at 150°C? Mastering Self-Combustion Synthesis

- How is a high-temperature box furnace utilized during the calcination and sintering stages of SrVO3 precursors?

- What customization options are available for muffle furnaces? Tailor Your Furnace for Peak Performance

- What is the function of a high-temperature lift furnace in the sintering process of SSZ electrolyte pellets?

- What are the disadvantages of using a muffle furnace? Key Limitations and Better Alternatives