In materials science, the significance of a muffle furnace lies in its ability to create an extremely controlled, high-temperature environment that is completely isolated from heating elements and their byproducts. This combination of precise temperature control and a non-contaminating atmosphere is essential for developing, testing, and preparing a vast range of materials, from advanced alloys to medical samples.

The core value of a muffle furnace is not just heat, but purity of process. By separating the material being tested from the source of heat, it ensures that experimental results are a true reflection of the material's properties, free from outside contamination.

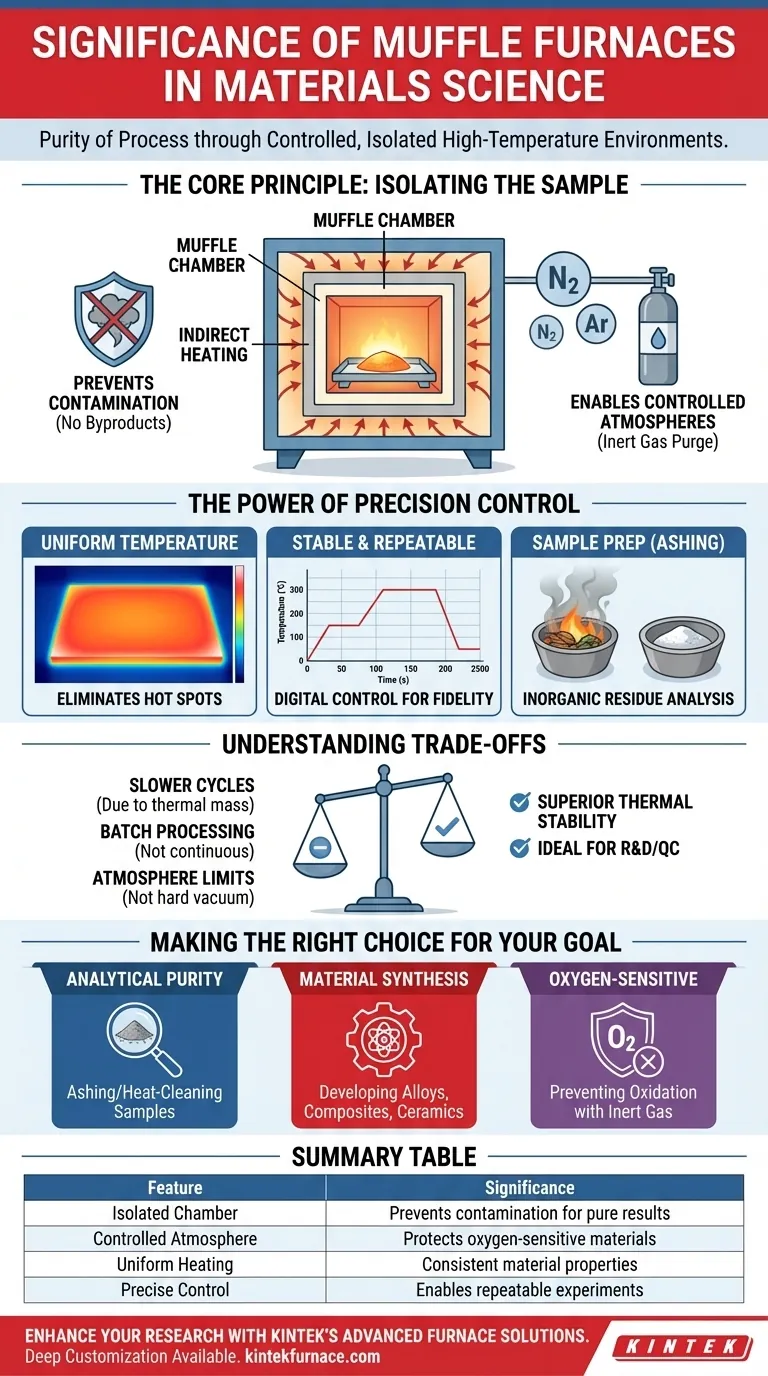

The Core Principle: Isolating the Sample

The defining feature of a muffle furnace is its design, which is the source of its most critical advantages in a research or quality control setting.

The 'Muffle' Chamber

A muffle furnace contains an inner chamber, or "muffle," that holds the sample. The heating elements are positioned outside this chamber.

This design creates an indirect heating system. The elements heat the chamber, and the chamber, in turn, radiates heat uniformly onto the material inside.

Preventing Contamination

The primary benefit of this separation is the prevention of contamination. In a direct-fired furnace, byproducts of combustion (like gases and soot) can directly interact with the sample.

A muffle furnace ensures that the material is only exposed to the intended heat and atmosphere inside the chamber, which is critical for achieving pure, repeatable results. Materials like high-temperature alloys or specialized ceramics are used to construct the muffle, providing resistance to aggressive gases.

Enabling Controlled Atmospheres

Because the inner chamber is isolated, the atmosphere within it can be controlled. Some models allow for the introduction of inert gases, such as nitrogen or argon.

This is indispensable when heat-treating materials that oxidize easily at high temperatures. By displacing oxygen, the furnace prevents unwanted chemical reactions that would alter the material's fundamental properties.

The Power of Precision Control

Beyond isolation, muffle furnaces are valued for their ability to deliver stable and uniform temperatures, which is a non-negotiable requirement for serious materials research.

Uniform Temperature Distribution

The indirect heating method naturally promotes a highly uniform temperature environment. It eliminates "hot spots" that can occur with direct heating, ensuring the entire sample experiences the same thermal conditions.

This uniformity is vital for processes like firing ceramics or annealing metals, where even small temperature variations across the material can lead to defects, internal stresses, or inconsistent properties.

Stable and Repeatable Processes

Modern muffle furnaces offer precise digital control over temperature ramps, soaks, and cooling rates. This stability ensures that experiments can be repeated with a high degree of fidelity.

When developing new materials like nanomaterials or composites, the ability to replicate the exact thermal cycle is the only way to reliably correlate process variables with final material performance.

Sample Preparation (Ashing)

A common application is the ashing of samples, particularly in pharmaceutical or medical research. In this process, a sample is heated to a high temperature to burn off all organic material.

What remains is an inorganic residue (ash) that can be analyzed without interference from the organic components. The controlled, contaminant-free environment of the muffle furnace is perfect for this type of sample pretreatment before techniques like spectroscopy.

Understanding the Trade-offs

While indispensable, muffle furnaces are not the universal solution for all heating applications. Understanding their limitations is key to using them effectively.

Heat-Up and Cool-Down Rates

Due to the significant thermal mass of the insulating materials and the muffle itself, these furnaces can have slower heating and cooling cycles compared to other methods like induction or direct-resistance furnaces. This is the trade-off for superior thermal stability.

Atmosphere Limitations

While many muffle furnaces can operate with inert gas purges, they are not a replacement for a dedicated vacuum furnace. Achieving and maintaining a high-purity, hard vacuum is a different engineering challenge and requires specialized equipment.

Batch Processing vs. Continuous Flow

Most laboratory muffle furnaces are designed for batch processing. They are ideal for research, development, and quality control on individual samples or small lots, but less suited for high-throughput, continuous industrial production lines.

Making the Right Choice for Your Goal

Selecting the right thermal processing tool depends entirely on your primary objective.

- If your primary focus is analytical purity: A muffle furnace is the ideal choice for ashing or heat-cleaning samples, as it prevents contamination from combustion byproducts.

- If your primary focus is material synthesis: The precise, uniform, and repeatable temperature control of a muffle furnace is critical for developing new alloys, composites, and ceramics.

- If your primary focus is processing oxygen-sensitive materials: A muffle furnace with inert gas capability provides a controlled, low-oxygen environment essential for preventing oxidation during heat treatment.

Ultimately, the muffle furnace remains a foundational tool in materials science because it provides a reliable and uncontaminated environment to discover how materials truly behave under heat.

Summary Table:

| Feature | Significance |

|---|---|

| Isolated Chamber | Prevents contamination from heating elements, ensuring pure results |

| Controlled Atmosphere | Allows inert gas use to protect oxygen-sensitive materials |

| Uniform Heating | Eliminates hot spots for consistent material properties |

| Precise Temperature Control | Enables repeatable experiments and stable thermal cycles |

| Common Applications | Ashing, annealing, synthesis of alloys, ceramics, and composites |

Ready to enhance your materials research with pure, high-temperature processing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can drive your innovations forward!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing